155

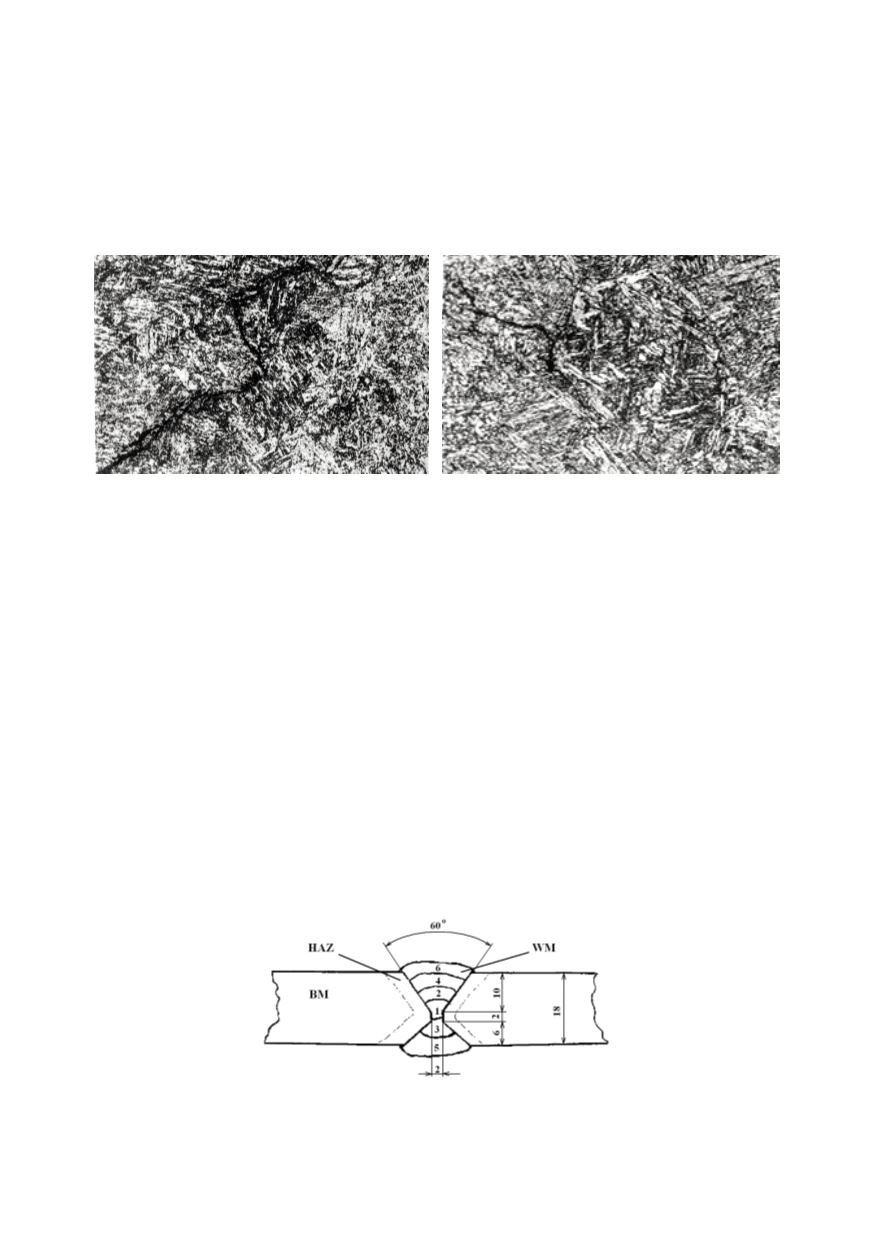

grained microstructure, where the development was trans crystal line. The occurrence of

these cracks required the application of empirical formulae for weldability assessment

and numerous technological tests (FISCO, CTS, Window, Tanaka, Y test) /20/. The tests

showed that NN70 is not prone to hot cracking if the electrodes and welding regime are

properly chosen. Although an applied under matching can prevent the occurrence of cold

cracks, they were found at the fusion line (Fig. 10) if the samples had been preheated

below 130

o

C, so proper welding procedure and its control was necessary.

Figure 9. Hot crack in weld metal

Figure 10. Cold crack at the fusion line

After experimental analysis, applying three different levels of heat input and an

analysis of the HAZ width and the obtained microstructure, it was possible to define a

proper Welding Procedure Specification (WPS) and produce defect-free welded joints.

The analysis included the determination of the nil ductility transition temperature. This

temperature was -74

o

C for the welded joint, according to ASTM E-208, and

-85

o

C for the HAZ and -25

o

C for the WM, according to the 50% Charpy energy.

6.1. Preparation of welded samples and qualification of the welding procedure

The welding technology and regime were chosen in accordance to the properties and

basic microstructure of NN70 steel. The shape of the welded joint was designed to

simulate the best stress distribution in real structures. Samples for experimental investiga-

tions were prepared by manual arc welding (MAW) of the metal following a defined

WPS. Two plates of NN 70 steel, 18 mm thick, prepared for an asymmetric 2/3 X welded

joint by edge machining (Fig. 11), were welded with a 2 mm gap. The chemical compo-

sition and mechanical properties of the applied electrode EVB 75 (according to EN 757:

E 69 4 Mn2NiCrMo B 42) are shown in Tables 6 and 7, respectively. Welding was per-

formed in six passes, with the heat inputs given in Table 8. Specimens of the welded

joint, WM and HAZ were machined from the welded plates for qualification (Fig. 12).

Figure 11: Welded samples were produced in six passes