154

3), produced in an electric furnace and subsequently slab-rolled to 18 mm

thick plates.

After hot rolling, the steel is quenched in water from 890

o

C and tempered at 660

o

C. The

properties (Tables 4 and 5) were obtained by combining classic quenching and tempering

with grain refinement, micro alloying and suitable precipitation.

The aim of this investigation was to determine the toughness and fracture properties of

the constituents of a welded joint (BM, WM and HAZ) and to assess any reduction of

these properties caused by welding. The chemical composition and mechanical properties

of NN70 steel are given in Tables 3 and 4, respectively; Charpy V energies obtained at

different temperatures are listed in Table 5.

The high strength of NN-70 steel is accompanied by good impact toughness in both

orientations (total impact energy greater than 65 J down to -80°C, Table 3) and a low nil-

ductility transition temperature (below -120°C for 50% Charpy V energy, -103°C in the

drop weight test, ASTM E208), significant crack initiation energy and resistance to crack

propagation at all testing temperatures. This combination of strength and toughness is

favourable for pressure equipment application.

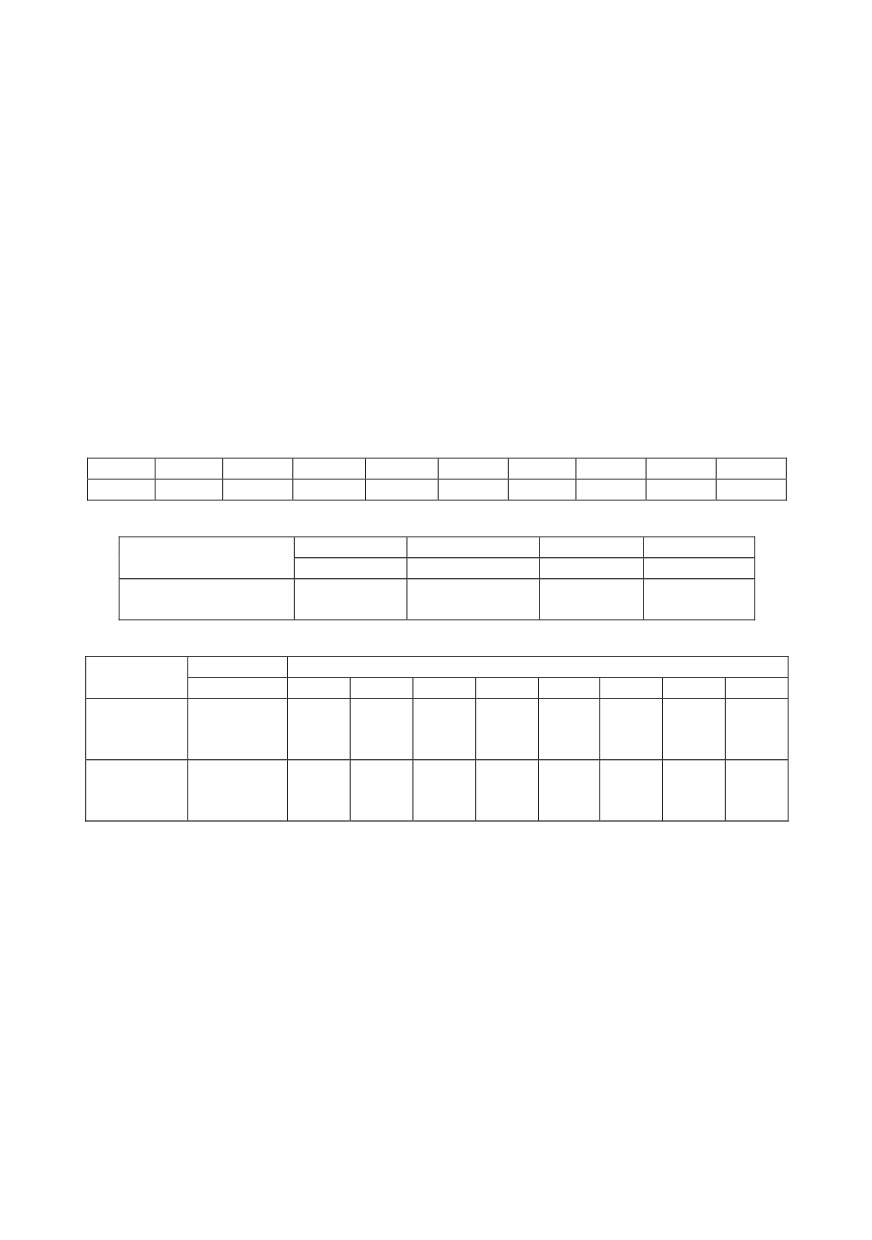

Table 3: Chemical composition of NIONIKRAL 70 steel, %

C

Si

Mn

P

S

Cr

Ni

Mo

V

Al

0.1

0.2

0.23

0.009

0.018

1.24

3.1

0.29

0.05

0.08

Table 4: Mechanical properties of NIONIKRAL 70 steel

Yield stress

Tensile strength

Elongation

Contraction

Specimen

orientation

R

p0.2

, MPa

R

m

, MPa

A

, %

Z

, %

Parallel to rolling

Perpendicular

780

770

820

810

19

20

66

74

Table 5: Charpy V absorbed energy of NIONIKRAL 70 steel

Energy

Testing temperature, °C

Specimen

orientation

J

20

-20

-40

-60

-80

-100

-120

- 140

Parallel to

rolling

Total

Initiation

Propagation

108

41

67

106

40

66

107

42

65

100

36

64

98

36

62

78

33

45

64

29

35

30

23

7

Perpendicular

Total

Initiation

Propagation

81

30

51

80

29

51

81

28

53

76

24

52

65

23

42

49

23

26

46

23

23

28

22

6

Because of low sulphur content, steel NN-70 is guaranteed without cracks, A class.

The applied CaSi treatment resulted in globular MnS, without MnS inclusions shape

responsible for lamellar tearing, enabling to apply NN-70 steel also for welded T joints.

The weldability and cracking susceptibility of high strength steels can be serious pro-

blems in application /21-23/, requiring the consideration of the risks of cracking during

fabrication and of failure during service. The most important aspects of weldability are

the sensitivity of the WM and the HAZ to any type of cracking during or after welding,

behaviour related to brittle fracture and the mechanical and technological properties of

the welded joint, macro- and micro-analysis of the BM, HAZ and WM. In spite of

precautions taken in the first stage of the weldability analysis of NN70, it was not possi-

ble to avoid cracks, because experience with the welding of HSLA steel was limited. A

hot crack which developed inter crystal line between the dendrites in the cast structure of

the WM, is presented in Fig. 9. A cold crack (Fig. 10) occurred in the transition fusion

region in the cast structure of the weld metal and in the HAZ region of dominant coarse-