158

Figure 13: Transition region at the fusion line:

WM cast microstructure, left, and coarse-

grained HAZ region, right, with a visible fusion

region between them

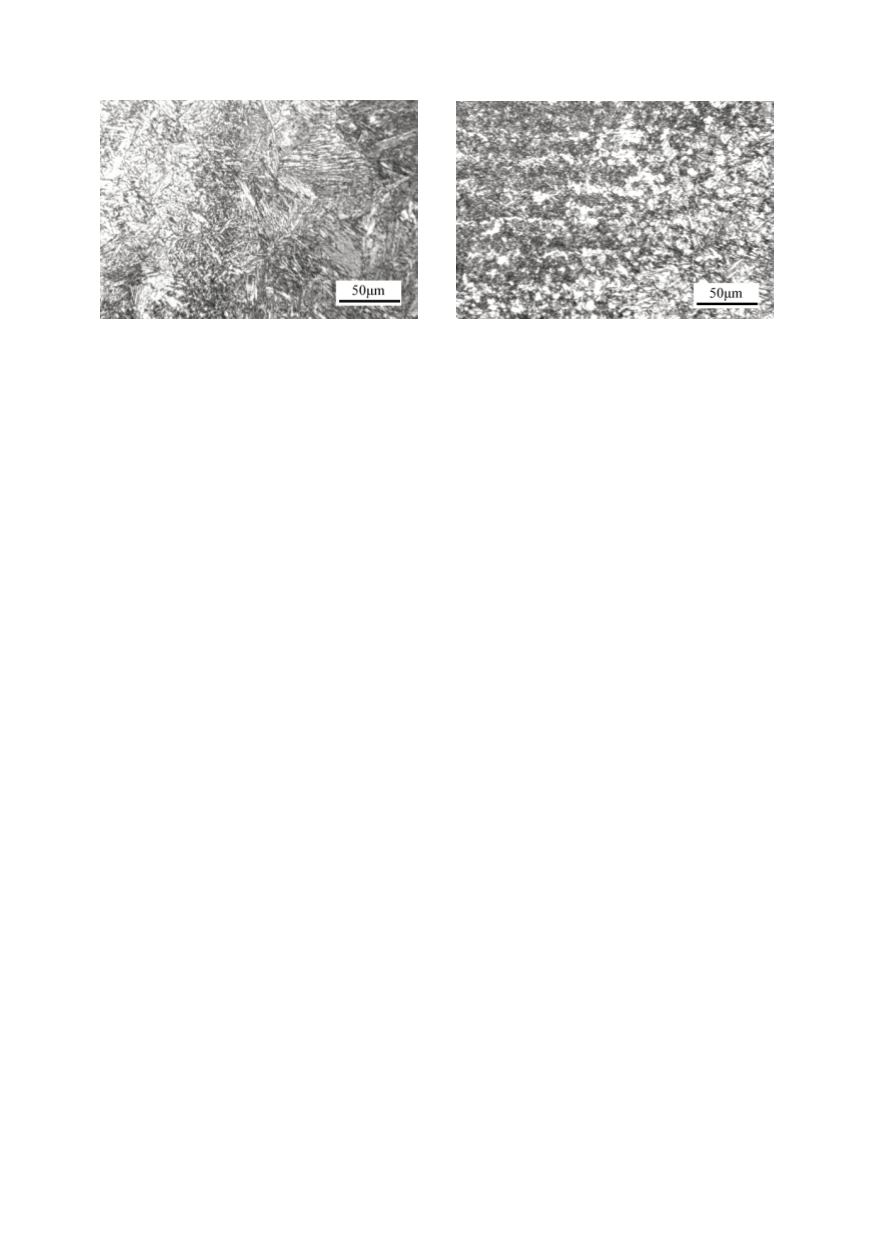

Figure 14: Transition region between the

directed fine grains of rolled BM, left, and the

fine-grained bainite of the tempered HAZ, right

The size of the HAZ is limited and the regions of different microstructures too small

for an evaluation of their mechanical properties. In the case of NN70 steel, the HAZ

microstructure consisted of bainite of different grain sizes. Upper bainite of CG (location

1) in the vicinity of the fusion line (with an eventual martensite region, but not clearly

recognized here) is followed by lower bainite (location 2) and FG tempered bainite

similar to the BM (location 3) in the middle, and by lower bainite at the end (location 4,

Fig.15). It should be noticed that the transition between the bainite regions is smooth.

Due to different microstructures in the regions, the mechanical properties, including

impact toughness and crack resistance, can differ significantly, affecting the overall

response of a welded joint specimen.

Regarding structural integrity, the response of the HAZ as a whole is important and

the obtained HAZ microstructure, being of the same type, is favourable, in spite of its

complexity caused by the differences in the size of the grains. Welded joint design has to

accommodate as much as possible to the expected service loading and an X-shaped

welded joint, (Fig. 15), is recommended and accepted here for welding qualification and

WPS. For this reason, the notch root in Charpy V and the crack tip in pre-cracked speci-

mens were located as presented in Fig.15. The obtained results represent an average

response of the loaded HAZ to the involved stress concentration and local constraint.

An evaluation of the mechanical properties is possible by HAZ simulation, which

enables samples of sufficient size (11x11x55 mm) to be obtained. It was successfully

applied to different steels of increased strength for pressurized equipment /21/. The per-

formed analysis with normalized V micro alloyed NIOVAL 47 steel of TSt 460 class

(nominal yield strength 460 MPa) revealed the presence of a very brittle CG region in the

HAZ close to the fusion line, which resulted in a loss of structural integrity of spherical

storage tanks by crack initiation and growth during service /22/. The differences in the

microstructure in the HAZ were not so expressed, and only an average response regarding

local properties, such as crack resistance and impact energy, of the HAZ as a constituent

of welded joints was required.

Applying the approach, proposed by Kfouri /23/, which demonstrated that a fracture

process could be discontinuous, to the complex HAZ microstructure (Fig. 15), it can be

supposed that the final stretch zone, as well as the process zone is not uniform along the

crack tip, being dependent on the local microstructure. It is to expect that these zones are