161

They allow the determination of

J

Ic

, a measure of fracture toughness, which is used for

the calculation of the critical stress intensity factor,

K

Ic

:

2

1

Ic

Ic

J E

K

ν

⋅

=

−

(3)

where

E

is the elasticity modulus, and

ν

the Poisson ratio. The obtained results for

J

Ic

and

K

Ic

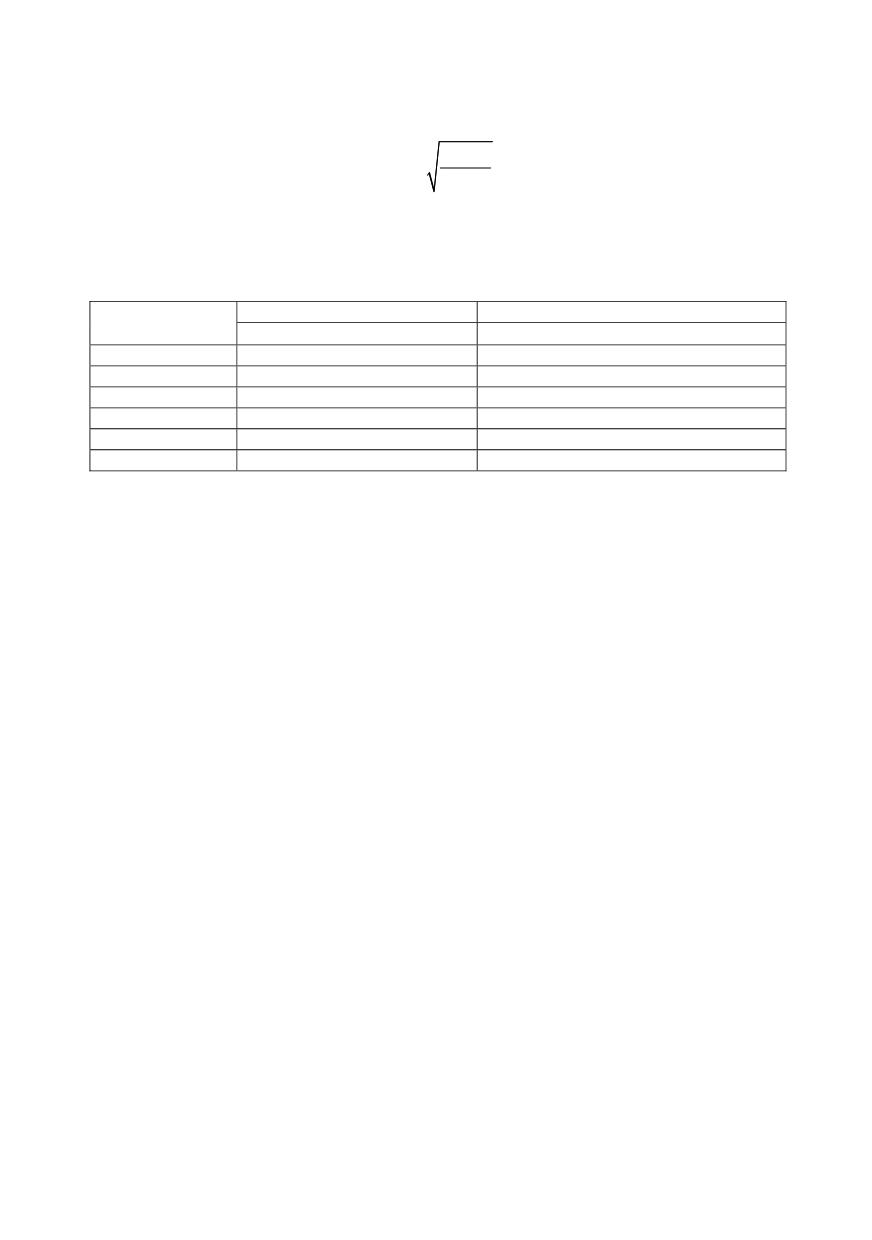

are summarized in Table 12. The differences in the crack resistance of the BM, WM

and HAZ are clear. Similar relations were obtained with dynamic J-R curves /27/.

Table 12: Results of testing the critical J-integral,

J

Ic

, and the critical stress intensity factor,

K

Ic

.

Critical

J

-integral,

Critical stress intensity factor,

Specimen No.

J

Ic

, kJ/m

2

K

Ic

, MPa

√

m

BM-1

117,4

157,7

BM-2

124,6

162,5

WM-1

67,6

119,7

WM-2

63,7

116,2

HAZ-1

102,2

147,2

HAZ-2

97,5

143,7

7. DISCUSSION AND CONCLUSION

The presented analysis was performed in the scope of the qualification of a welding

procedure for NN70 steel, with the aim of understanding the degradation of the properties

caused by welding. The slight under matching in the strength of the WM (Tables 4; 7;

and 9), did not significantly affect the tensile strength of the welded joint.

The effect the size of the specimens and how the obtained results can be transferred to

the welded joints of a real structure require more attention. The relations of the values of

the critical J-integral,

J

Ic

, and critical stress intensity factor,

K

Ic

, for the BM, WM and

HAZ (Table 12.) just confirm that the fracture mechanic approach is significant tool in

structural integrity assessment of welded joints /20/.

Finally, this lecture and conclusions clearly confirm that fracture mechanics testing of

welds are significant for structural integrity of structures with welded joints.

REFERENCES

1.

K. Easterling,

Introduction to the Physical Metallurgy of Welding

, Butterworth – Heinemann

ltd., ISBN 0 7596 0399 1, second edition, Oxford, GB, 1992, pp42, 191 - 239

2.

Barsom, J.M, Rolfe, S.T, Fracture and Fatigue Control in Structures: Applications of Fracture

Mechanics, 3rd ed, ASTM, 1999 pp 237 – 250

3.

George Dieter, Mechanical Metallurgy, SI Metric Edition, McGraw-Hill, 1988, pp 474 - 477

4.

The Welding Engineer´s Current Knowledge, DVS Duisburg, 1999

5.

ASM Handbook Volume 11,

Failure Analysis and Prevention

, ASM International (2002)

6.

Lassen T, Recho N,

Fatigue life analyses of welded structures

, ISTE Ltd, 2006, pp 20-22

7.

Grabulov V.,

Contribution of the evaluation of brittle fracture behaviour of high strength

pressure vessels steels weldments

, International conference "Pressure Equipment Sector in

Europe and Reflections in The Republic of Macedonia - Quality Assurance and Integrity

Assessment", Skopje, 2005, Collection of invitation papers,p.119-127

8.

D. Momčilović, I. Atanasovska, V. Grabulov,

Behavior of Metals under Impact Loading

,

Proceedings of 1. International Congress of Serbian Society of Mechanics, Kopaonik, 10-

13.04.2007., ISBN 978-86-909973-0-5.

COBISS.SR-ID 138952460, Serbian Society of

Mechanics, Belgrade, pp. 1053...1058