150

where

C

is a constant, depending on specimen and crack geometry,

σ

,

MPa, is nominal

stress, and

a

, mm,

is crack size. One of the basic principles of fracture mechanics is that

unstable fracture occurs when the stress-intensity factor reaches a critical value, Table 1.

For mode I loading (opening, tensile mode) and for negligible crack-tip plastic defor-

mation (plane-strain conditions), the critical stress-intensity factor for fracture instability,

K

Ic

, represents the inherent ability of a material to resist tensile crack extension. However,

this fracture-toughness property varies with constraint, and like other material properties

such as yield strength, varies with temperature and loading rate as follows.

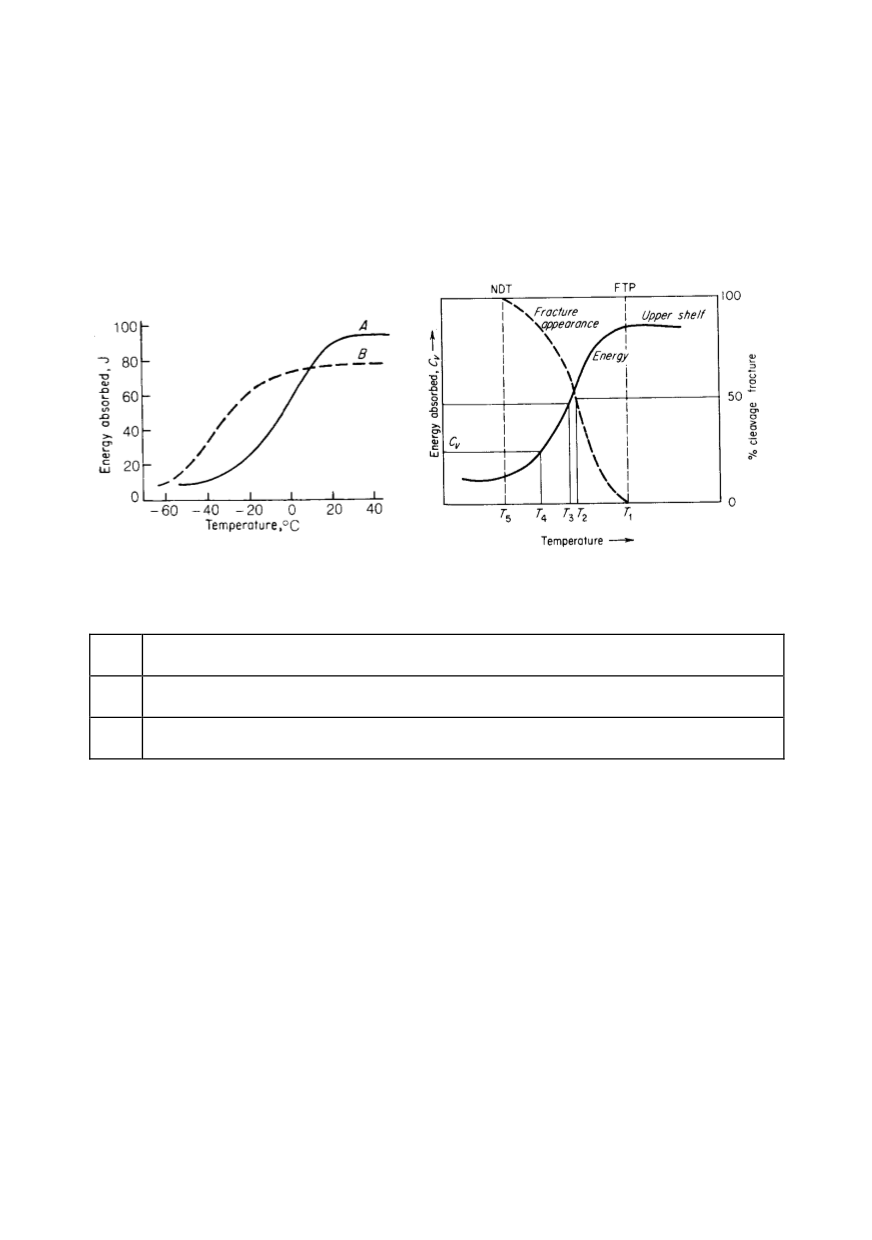

Figure 5: Transition-temperature curves for two steels, showing fallacy of depending on room-

temperature results (left), various criteria of transition temperature obtained in Charpy test (right)

Table 1: Stress-intensity factors

K

c

Critical stress-intensity factor for static loading and plane-stress conditions of variable

constraint. This value depends on specimen thickness and geometry, and on crack size.

K

Ic

Critical stress-intensity factor for static loading and plane-strain conditions of maximum

constraint. This value, a minimum value for thick plates, is material property.

K

Id

Critical stress-intensity factor for dynamic (impact) loading and plane-strain conditions of

maximum constraint.

Each value from Table 1 (

K

c

,

K

Ic

,

K

Id

), is also a function of temperature, particularly

for structural materials exhibiting a transition from ductile to brittle behaviour /9,10, 11/.

Knowing the critical value of

K

at failure (Table 1) for a given material of a particular

thickness and at a specific temperature and loading rate, the designer can determine flaw

sizes that can be tolerated in structural members for a given design stress level. Conver-

sely, the designer can determine the design stress level that can be safely used for an exis-

ting crack, present in a structure. In general, the relationship among fracture toughness

(

K

), stress (

σ

), and crack size (

a

) is shown schematically in Fig. 6 for through thickness

crack in a plate. The figure shows that there are for particular material many combina-

tions of stress and crack size (

σ

f

,

a

f

) that may cause fracture, and many of them (

σ

0

, a

0

)

when fracture will not take place, under slow loading and at given test temperature.

High-toughness structural materials undergo extensive plastic deformation prior to

fracture, and for them EPFM parameters are applicable. Crack-tip opening displacement

(CTOD), corresponding to slow loading rates is also applicable in LEFM, and the J-

integral, as an energy criterion for slow loading rates, is used in EPFM .

Based on either of them, crack resistance curve (R-curve) is defined, indicating frac-

ture resistance of material to stable crack growth.