157

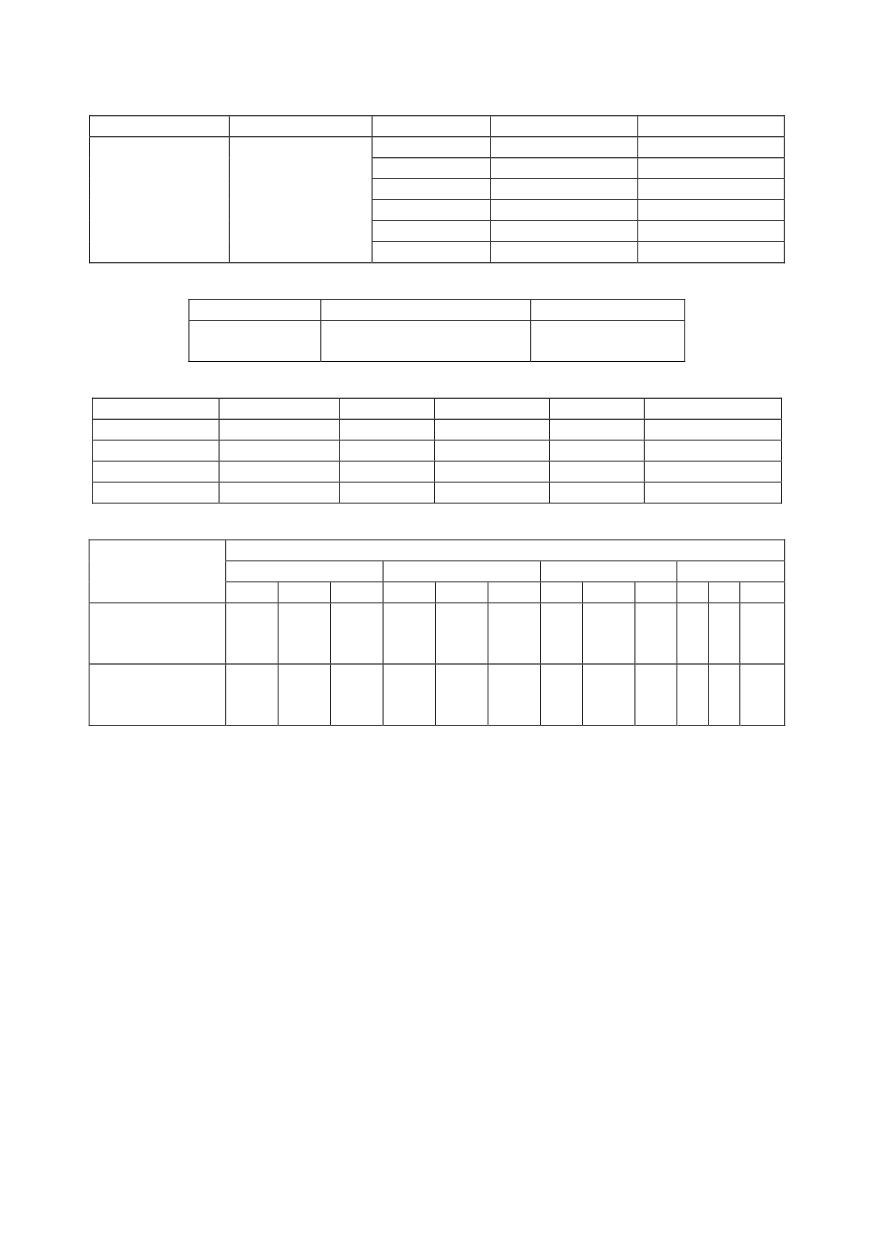

Table 8: Welding parameters for manual arc welding (MAW) of NN 70 steel

Base metal

Electrode

Pass

Diameter, mm

Heat input,

Q

, J/cm

1

3.25

16.9

2

3.25

15.1

3

4

19.4

4

4

20.4

5

4

18.9

NN70

EVB 75

6

4

19.0

Table 9: Tensile properties of the welded joint specimens.

Electrode

Tensile strength,

R

m

, MPa

Contraction,

Z

, %

EVB 75

766

759

68.8

67.7

Table 10: Results of guided bend test of welded joints

Specimen

Thickness, mm Filler metal Bending angle Bending on Fracture position.

7B2

18

EVB 75

30°

Face

Fusion line

7B20

18

EVB 75

180°

Root

Fusion line

7B3

18

EVB 75

30°

Face

Weld metal

7B30

18

EVB 75

180°

Root

No fracture

Table 11: Charpy energy (V-notch) of welded joint constituents

Charpy energy, J, at

20°C

- 60°C

- 100 °C

- 140°C

Notch

position

t

ini

pr

t

ini

pr

t

ini

pr

t ini pr

Weld metal

47

40

43

17

12

19

30

28

24

23

16

16

14

6

7

9

10

9

7

10

7

4

6

4

3

4

3

5

8

6

2

5

2

3

3

4

Heat-affected-

zone

64

123

64

35

80

47

29

43

17

53

91

72

43

51

50

10

40

22

99

48

58

89

27

37

10

21

21

t – total energy; ini – energy for crack initiation; pr – energy for crack propagation

6.2. The effect of microstructural heterogeneity on notch and crack resistance

The testing results obtained with V-notched and pre-cracked specimens depend on the

position of the notch root and the crack tip in the microstructure (Fig. 8). Although

different, the microstructures of the BM and WM are homogeneous and the scatter of the

obtained test results was not significant. However, the scatter of the results obtained for

the HAZ (Table 11) was significant due to microstructural heterogeneity and required

detailed analysis. The transition region at the fusion line, presented in Fig. 13, is positi-

oned between the cast microstructure of the WM, left, and the coarse-grained (CG) HAZ

region, right. On the other boundary of the HAZ (Fig. 14), there is a transition region

between the directed fine grains (FG) of the rolled BM, left, and the fine grains of the

tempered HAZ, right. Although the microstructure of the WM (Fig. 9) is a cast one, it

presents a continuous homogeneous metal of sufficient volume, enabling the determina-

tion of the WM properties, including notch and crack resistance. This is not the case with

the HAZ. Exposed to successive heat inputs, the microstructure of the HAZ in the regions

between two boundaries, given in Figs. 13 and 14, changed during welding. The details of

this microstructure are presented in Fig. 15 along the crack tip in a pre-cracked specimen.