159

smaller for the CG regions and extended for the FG regions, and fracture will propagate

in some locations, and in others will be arrested. The total energy released for fracture is

related to the crack front microstructure, representing the overall response of the HAZ.

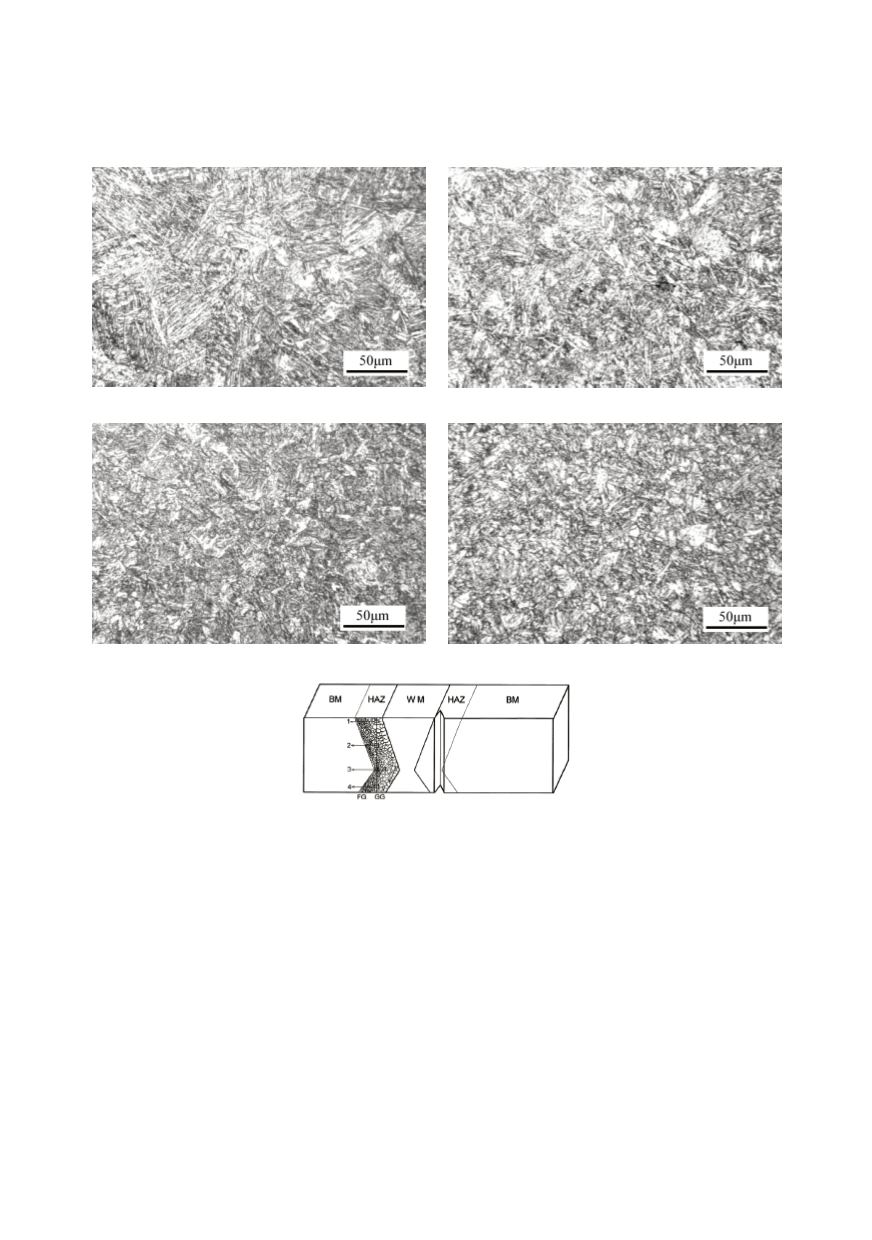

Location 1 – Coarse-grained - upper bainite

Location 2 - Lower bainite

Location 3 – Fine-grained - tempered bainite

Location 4 - Lower bainite

Figure 15: Microstructures along the crack tip in a fracture mechanics specimen

produced from a welded joint sample

It is also to expect that the response in the case of V-notch and crack tip will not be the

same since the involved stress concentration is not of the same level and different volu-

mes of metal are involved in the fracture process. If brittle behaviour prevails and causes

the crack occurrence, the structural integrity will be endangered, as experienced with

spherical storage tanks /24,25/. Otherwise, the structure can be considered as service-safe.

6.3. Determination of crack sensitivity and fracture toughness

To understand and evaluate the degradation of the BM properties caused by welding,

specimens with a V-notch, machined in the BM, WM and HAZ were pre-cracked by

fatigue (Fig. 16) and tested.

The crack tip in the HAZ specimens were located as indicated in Fig. 15, hence, due to

the X shape of the welded joint in, some cases, it could also encompass the BM or WM.

From the experimental point of view, a K-shaped welded sample is better /26/, since