153

toughness values for the same material are higher than those obtained as

K

Ic

or

J

Ic

values.

Advantages and disadvantages of fracture toughness tests are listed in Table 2 /8-14/.

The three-point bend and compact specimens (standardized in ASTM E 399 and E

813) are recommended for general laboratory materials evaluation, because

K

and

J

cali-

brations for these specimens are known and relatively low loads are required during

testing. Data obtained with non-standard specimens must be evaluated carefully to ensure

that the same fracture criteria are used, such as the onset of cracking.

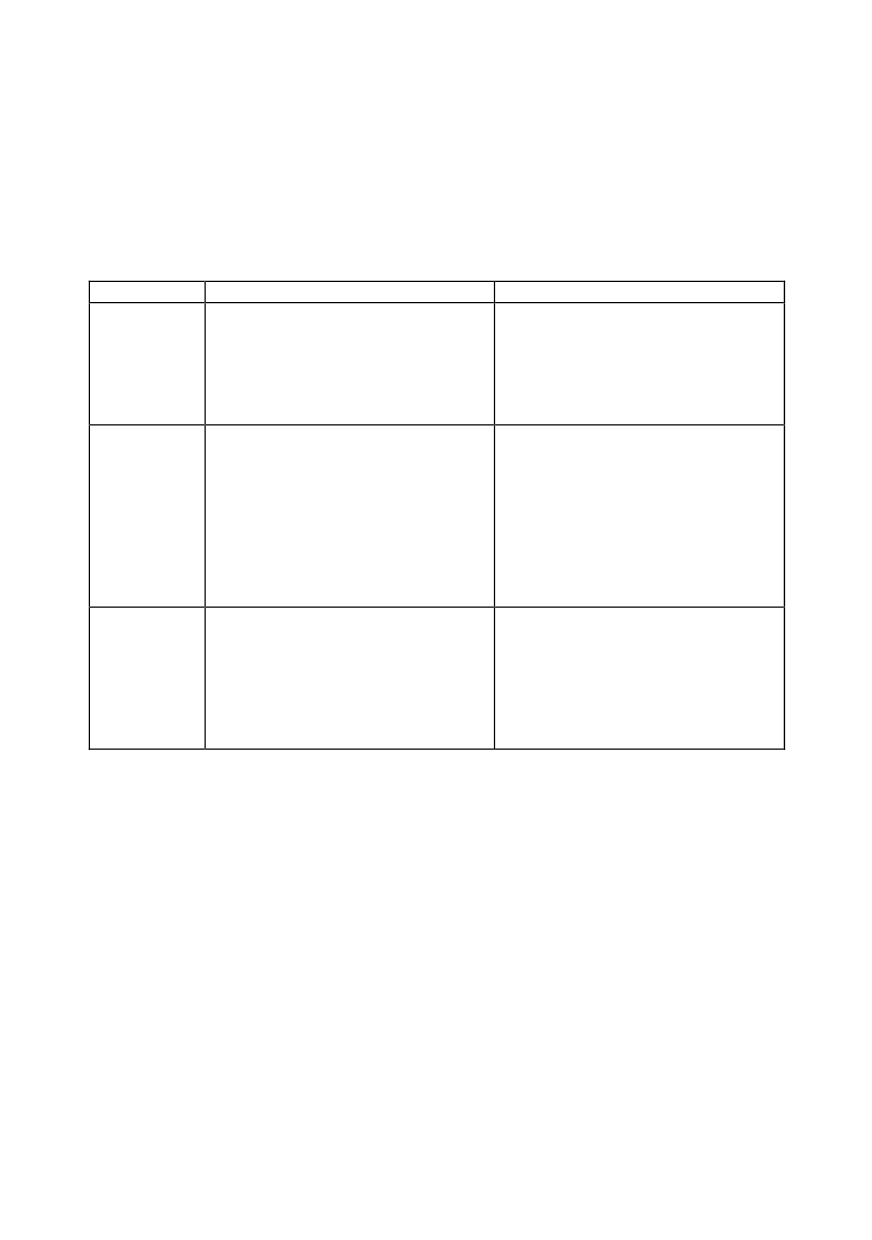

Table 2: Fracture toughness tests

Method

Advantages

Disadvantages

K

Ic

,

ASTM E 399

This method is the most reliable to get

fracture toughness values at lower

temperatures. The success of all other

methods is based on their ability to give

data comparable to this method.

The high cost of testing the large

specimens at high temperature tends to

reduce the number of data points. Linear

extrapolation from valid

K

Ic

at lower to

higher temperature is conservative. No

valid

K

Ic

values at high temperature.

J

-integral,

ASTM E 813

Provides fracture toughness values that

agree with

K

Ic

value. Fracture toughness

data at high temperature are realistic.

Sound theoretical basis permits evaluation

of stable crack growth. The value

dJ/da

is

a measure of the resistance to continued

crack propagation. Testing a series of

small

J

specimens provides an indication

of material toughness variation.

It is not possible to evaluate irregular

crack propagation due to residual stress or

at HAZ near welds. Not accurate enough

at low temperatures. Measurements are

inaccurate due to irregular crack fronts.

Not valid for thin materials where K

J

is

2.5

K

Ic

. When heat tinting is used, the

additional number of specimens increase

testing costs.

CTOD,

BS 7448

Provides fracture toughness values that

agree with

K

Ic

method. Fracture toughness

data at high temperature are realistic.

CTOD results are consistent and

comparable with the values of other

methods. Simultaneous measurement of

CTOD and

J

integral is possible.

Variations in the measurement of CTOD

(

δ

)

results in variations of

K

Ic

up to a

factor of 2. This method is restricted to

temperatures above -60°C.

A proper use of fracture-mechanics methodology for fracture control of structures

necessitates the determination of fracture toughness for the material at the temperature

and loading rate representative of the intended application. The morphology of fracture

surfaces for steel can be understood by considering the fracture-toughness transition

behaviour under static and impact loading, depicting the mode of crack initiation at the

crack tip for static, and the mode of crack propagation for dynamic loading.

This is to emphasize that one of the key problems regarding accuracy of fracture

mechanic testing of welded joints specimens is notch positioning, Fig. 8 /15/.

Experimental work experienced in methodological approach can help, as an example,

to understand better fracture mechanics parameters for BM, HAZ and WM, determined as

static and impact crack properties of high strength steel welded joint were tested /16 - 20/.

6. EXPERIMENTAL INVESTIGATION

Experimental investigations of the static and impact properties have been performed

with high strength (HSLA) steel NIONIKRAL 70 (NN70) of nominal yield strength 700

MPa, designed for pressure equipment in process industry and in shipbuilding, e.g. for

submarines. This is a quenched and tempered (Q&T), low alloy, Ni-Cr-Mo steel (Table