334

plastic strains extend to about 10

-4

cm. Crack tip is connected with every picture in Fig.

13, so it can be attributed to all presented levels, but with different approaches. Intention

to approach crack tip as close as possible enabled the developement of new and more

detailed models. An additional impression about the complexity of crack tip region and

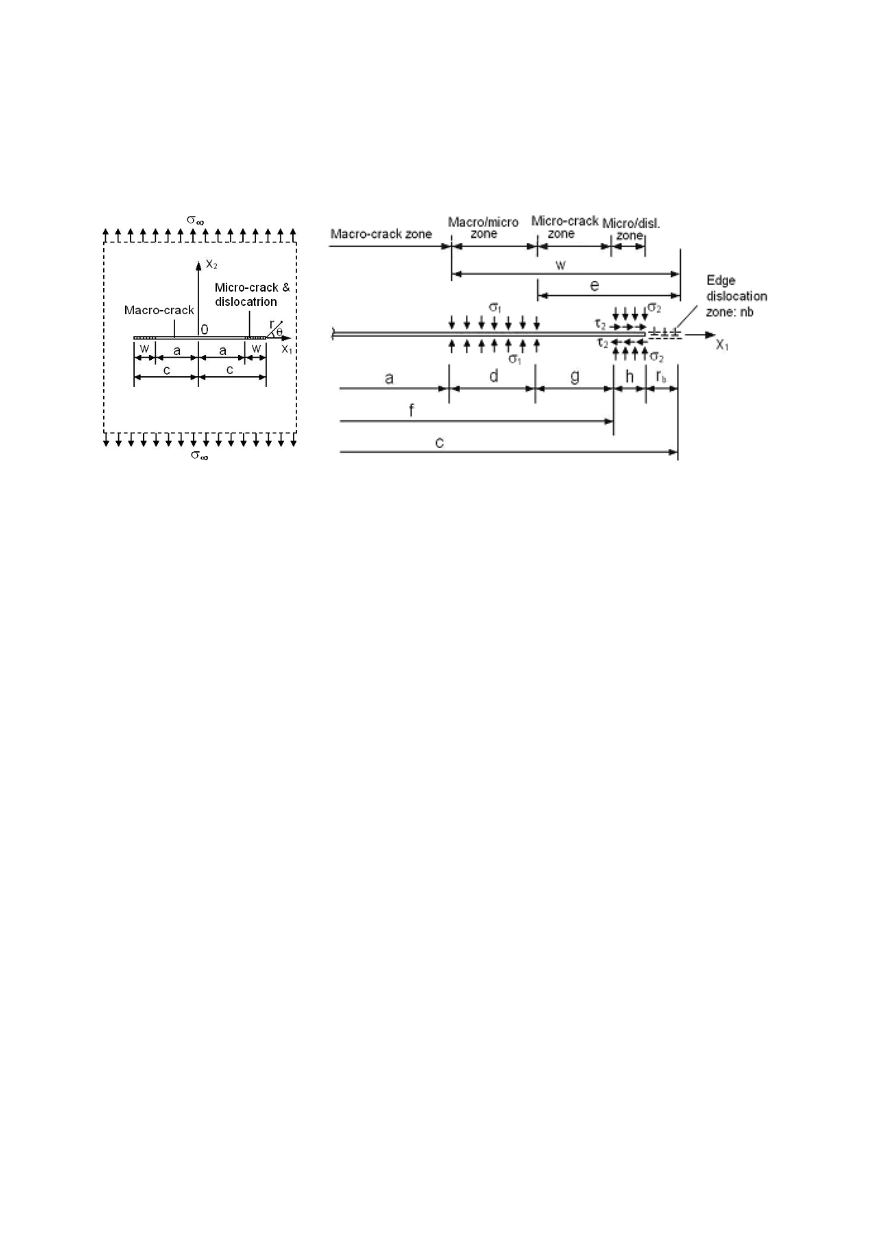

refinement of situation depicted in Fig. 13 can be obtained from Fig. 14 /19/.

Figure 14. Presentation of macro/micro/dislocation model with one-half symmetry /19/

In the areas of material science and continuum mechanics, the field of mesome-

chanics /20/ attracted attention owing to the necessity of scaling shifting in size and time.

The impetus of nanotechnology reached down the scale such that all disciplines would

meet and benefit from one another. However, there are overwhelming difficulties

associated with the discontinuities of results from the various scales, but also some basic

notion connected with the stress and strength require more detailed and better definition

when nano materials and structures are considered. Mesoelectronics has discovered that

the heat transfer behaviour of small bodies is distinctly different and requires funda-

mental studies of electronics at the subatomic scale. New physical laws may have to be

discovered to fill in the gaps. The final answer lies in multiscaling where the results at

the smaller scales must be translated to the macroscopic level. However this problem is

well known even at the macro scale when the results obtained with small sized speci-

mens should be applied to large components /21/.

For those problems where the physical process also calls for scaling in time such that

chemical reactions at the microscopic scale will also have to be considered in conjun-

ction with geometric continuum mechanics. Among the physical problems involved are

aerodynamic stability of solids moving through fluid media in the transonic region where

the traditional scaling scheme fails, like high speed projectile/target penetration with

phase transition from solid to liquid to gas, the aging of polymeric and metallic materials

where chemical reactions would alter the structural arrangements of the molecules owing

to specimen size, time and temperature effects, and high temperature creep and combus-

tion. The association of results at the atomic, microscopic and macroscopic scales has

been made difficult because the possibility to transfer the results is questionable. All

mentioned affects fracture behaviour considered at different scales.

Modern view on scaling of mater phenomena is presented in Fig. 1 /4/. Comparing

Figs. 13, 14 and 1 one can conclude that usually accepted range of fracture mechanics

application corresponds generally to the level of micro word and above it. Fracture

mechanics eventually could be applied at the level of nano word, but additional conside-