331

Sharp initial crack

Crack blunting

Crack growth in

plastic region

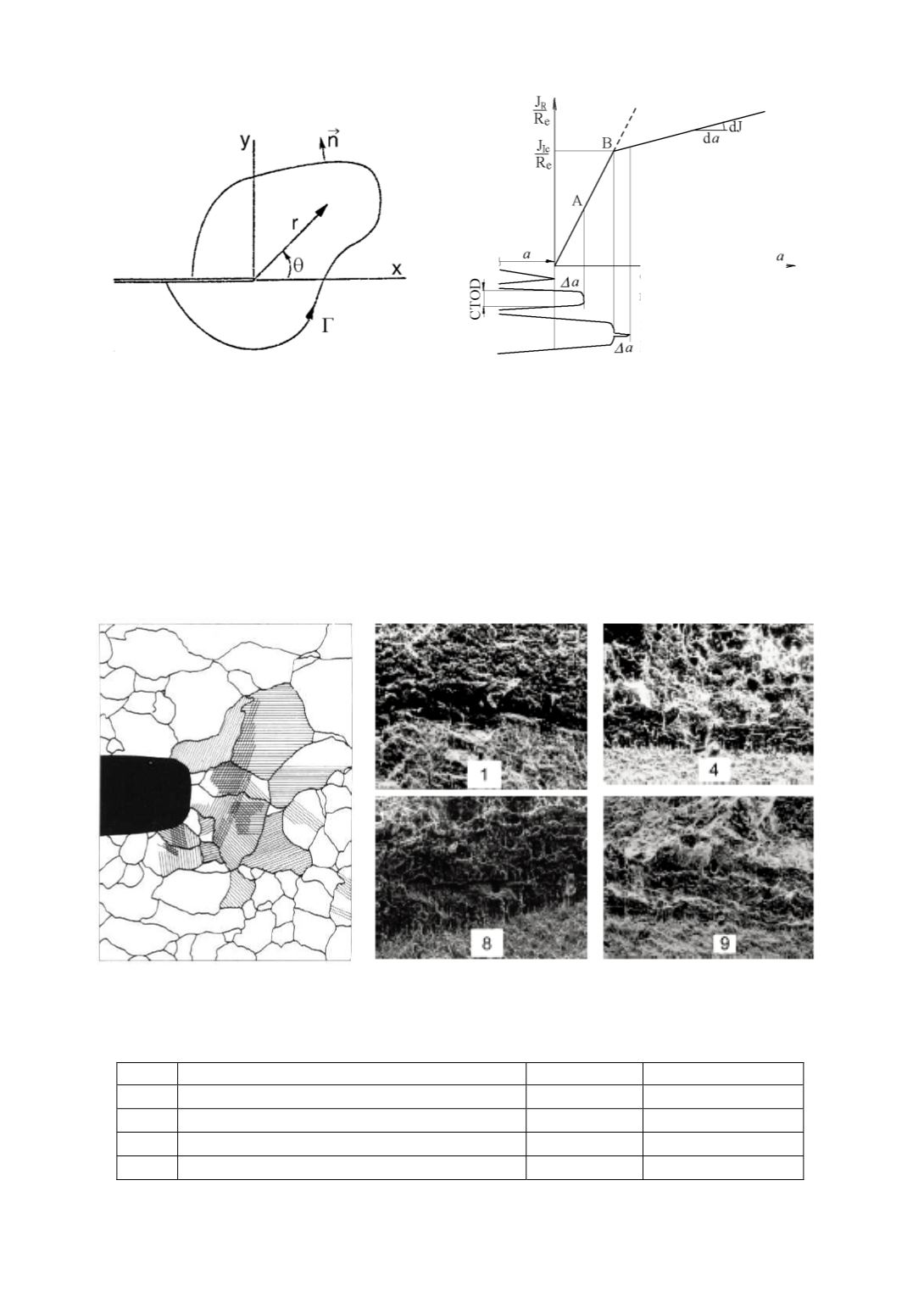

Figure 9. Arbitrary contour path for

J

integral Figure 10. Stable crack growth defined by J integral

When a large stretch zone at crack tip is developed, the crack-opening stress must

exceed the yield stress to cause plastic fracture and stable crack growth. If a small degree

of crack tip blunting is developed, the fracture is of elastic-plastic type. The elastic term

signifies that the fracture is developed for elastic crack-opening stresses, up to the point

B in Fig. 10, which indicates the final stretch zone, next FM parameter. Figure 11

illustrates that the crack tip blunting is the result of plastic slip within the grains. That is,

slip is developed prior to micro cracking of the grains. In the case of welded joint dif-

ferences in fractograms (Fig. 12) indicate the complexity of the problem.

Figure 11: Mechanism of crack tip

blunting

Figure 12. Final stretch zone recognized after point B

in Fig. 11 for different regions in welded joint (see Table 1)

Table 1: Final stretch zones for weld metal and heat-affected-zone /14/

Sample

Position

Temperature Final stretch zone

1

Weld metal

20

°

C

0.14 mm

4

Heat-affected-zone 0.5 mm from fusion line

20

°

C

0.19 mm

8

Heat-affected-zone 0.2 mm from fusion line

-60

°

C

0.44 mm

9

Heat-affected-zone 0.5 mm from fusion line

-60

°

C

0.23 mm