329

The critical

K

value,

K

Ic

, is material characteristics and can be determined experimen-

tally using corresponding standard, e.g. plane strain fracture toughness, ASTM E399. It

is to mention that plane strain condition must be fulfilled in

K

Ic

testing, and for that two

requirements are prescribed in standard: very sharp crack with plane strain state at the tip

(fatigue crack), and sufficient thickness of specimen to prevent plane stress state and

shear lips. The required thickness for brittle material is small, but size for ductile material

could be so large that can not be tested on available equipment.

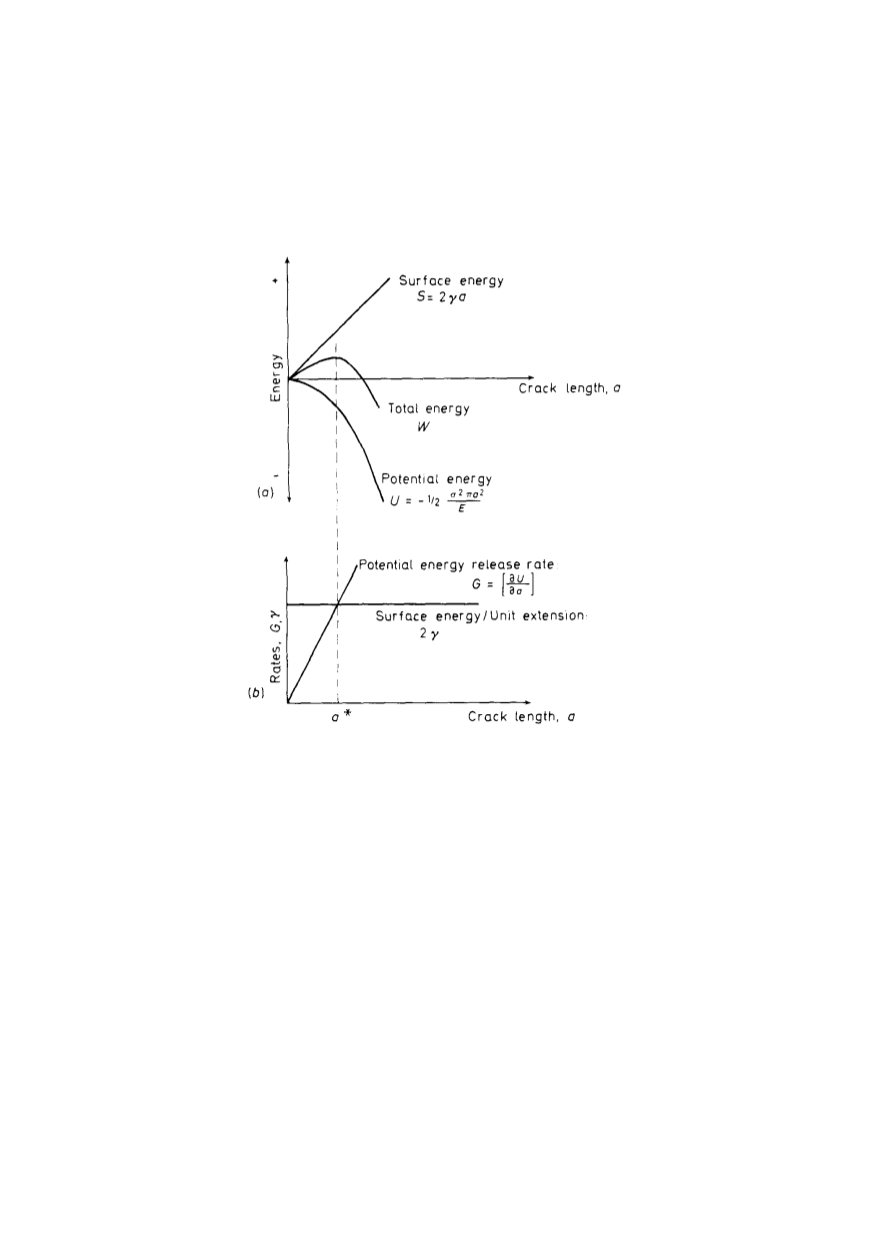

Figure 8: Variation of energy with crack length (a) and of energy rate with crack length (critical

Griffith’s crack length is denoted by

a

*)

Structure is safe and reliable if the applied stress intensity factor

K

is less than plane

strain fracture toughness

K

Ic

of material:

K

≤

K

Ic

(11)

Linear elastic fracture mechanics can be applied to problems in which the plastic zone

ahead the crack tip is small compared to the crack length. Fracture is then characterized

by the plane strain fracture toughness,

K

Ic

, and the decisive value for brittle fracture is

surface energy

γ

. In circumstances dominated by plane stress, the plastic zone is larger;

nevertheless, if failure still occurred at net section stress levels which are much lower

than the yield stress, problems may still be tractable by LEFM based methods /11/.

2.2. Elastic-plastic fracture mechanics (EPFM)

Since the fracture in steel and metallic materials frequently occurs after significant

plastic deformation, a different approach was then necessary. Introducing path indepen-

dent contour integral (J integral), defined by Rice /12/, it was possible to extend the frac-

ture mechanics to elastic-plastic behaviour (elastic-plastic fracture mechanics – EPFM).