179

MICROSTRUCTURAL ANALYSIS OF CRACK TIP REGION

Katarina Gerić

Faculty of Technical Sciences, Novi Sad, Serbia

gerick@uns.ns.ac.yu1. INTRODUCTION

The fracture develops from the crack tip. The investigation of crack propagation, the

analysis of the stress fields ahead the crack tip, and the microstructural analysis, including

fracture surface are inevitable parts in understand fracture process.

2. BRITTLE FRACTURE

The fracture is usually initiating from crack already present in material and developed

by crack growth. Local stress increase, caused by flaws in the material, significantly con-

tributes to fracture development. When the development of deformation is restrained the

fracture of metals is of brittle type in the Griffith sense. Anyhow, metal does not behave

in an ideally brittle manner and the plastically deformed zone on the crack tip occurs.

When its size is neglectible compared to component dimension and crack size, resulting

fracture can be considered as a brittle one. It is to underline that once started brittle

fracture will developed by cleavage mechanism, with no additional energy consumed.

Cleavage involves breaking bonds: the local stress must be sufficient to overcome the

cohesive strength of the material, which is higher than the remote stress required to cause

fracture. In order to initiate cleavage, there must be a local discontinuity ahead of the

macroscopic crack, sufficient to exceed the bond strength. Sufficiently sharp micro crack

can produce local stress concentration. Cottrell suggested that micro cracks by dislocation

interaction form at intersecting slip planes. However, more common mechanism for

micro crack formation in steel is connected with inclusions and second–phase particles.

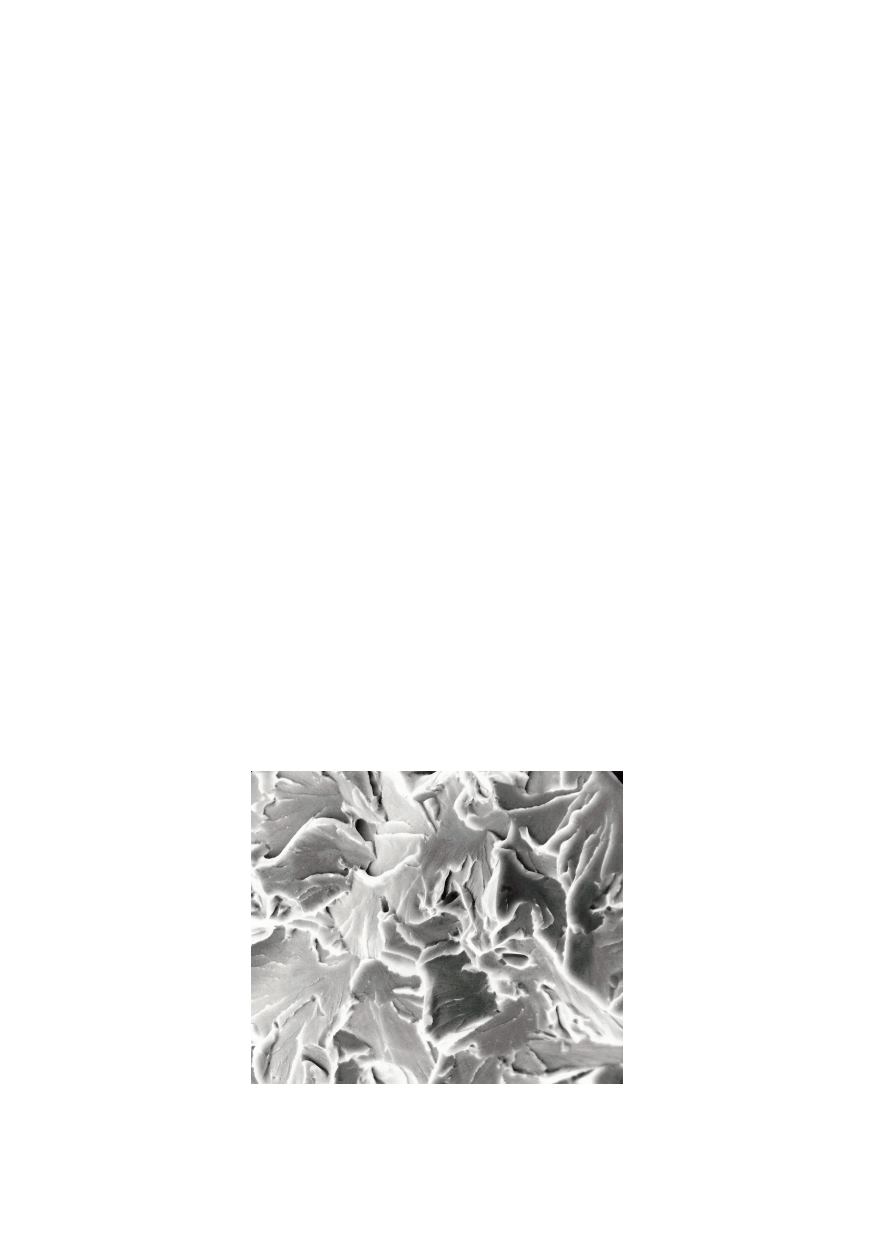

Figure 1 shows scanning electron microscope (SEM) fractograph of a cleavage fractu-

re in high-strength low-alloy (HSLA) steel /1/.

Figure 1: SEM fractograph of cleavage in steel (2000x)