182

more difficult to perform, mainly due to the problems associated with identifying the

various stages of the fracture process.

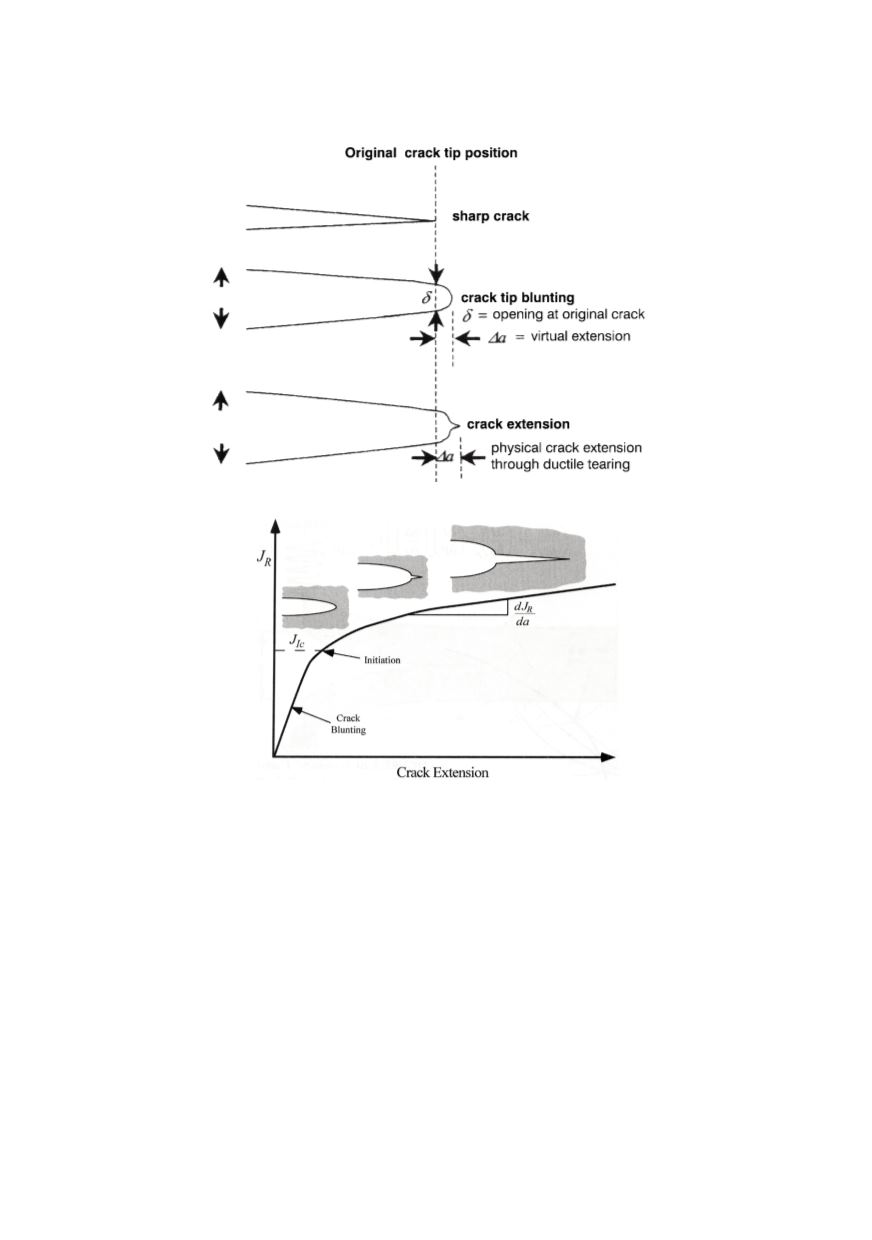

Figure 5: Schematic of crack extension process in a ductile material

Figure 6: Schematic J integral vs. crack extension for ductile material - resistance curve

Thus, if a SZD measurement is going to be used, it is necessary to specify clearly the

methodology. Apart from accuracy in determining the fracture toughness of ductile mate-

rial, it is sometimes necessary to examine the nature of the variation when factors affec-

ting the toughness, such as the yield strength and strain-hardening exponent, can vary.

Literature which considers the convenience of the SZW or SZD in

predicting the nature of

the variation in fracture toughness with material properties is limited.

5. METODOLOGY FOR STRETCH GEOMETRY MEASUREMENT

Stretch-zone depth (SZD) measurements are not straightforward, but rather the values

have to be calculated from indirect measurements /9/. A blunted crack configuration is

shown in Fig. 9.a. In the figure, the SZW is the projected length (

w

) of the stretch zone

when viewed at 90° to the crack plane. In Fig. 9.b the specimen is tilted through an angle

α

and

stretch zone projection on the plane normal to the viewing direction is observed.