180

The multi faced surface is a typical cleavage, each facet indicates single grain. The

“river patterns” on each facet are typical of cleavage fracture, indicating that multiple

lines converge to a single one, like river confluants.

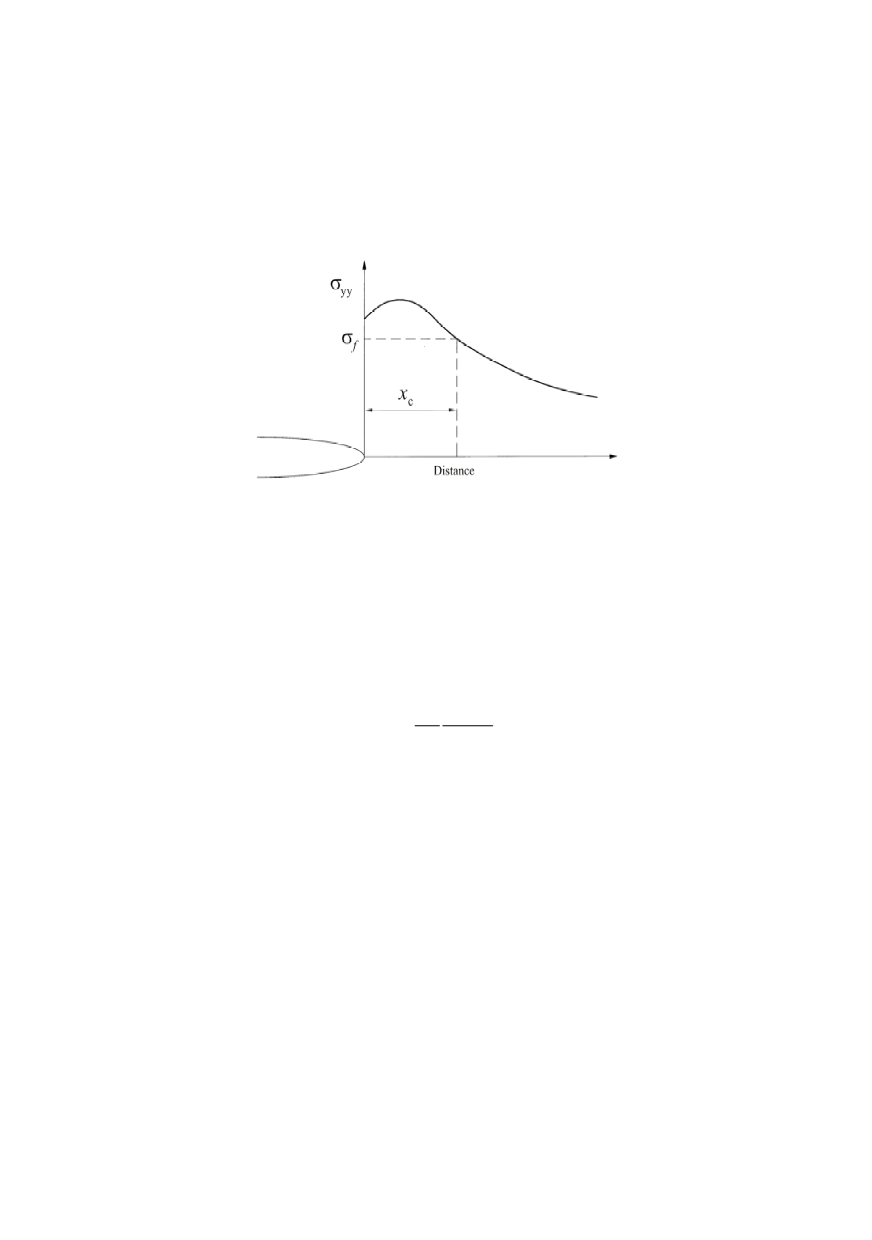

Ritchie, Knott and Rice /2/ introduced a simple model to relate fracture stress to frac-

ture toughness, explaining why brittle steel does not fracture upon a minimal load is

applied. They postulated that cleavage fracture occurs when the stress ahead of the crack

exceeds

σ

f

over the characteristic distance, Fig. 2, which equals to two grain diameters.

Figure 2: Ritchie-Knott-Rice model for cleavage fracture: failure is assumed to occur when the

fracture stress is exceeded over a characteristic distance

x

c

/2/

3. PLASTIC ZONE

Linear elastic stress analysis of sharp cracks predicts infinite stresses at the crack tip.

In real metals, however, stresses at the crack tip are of finite value due to the crack tip

blunting of finite radius size took place, followed by plastic (yielding) zone. The plastic

zone size estimation for plane stress conditions is

( )

(

)

2

1

2

I

y

YS

K

r

π σ

=

(1)

where

K

I

is stress intensity factor and

σ

YS

is yield stress.

If strain hardening effect is neglected, the stress distribution for

r

=

r

y

can be presented

by horizontal line at

σ

yy

=

σ

YS

, Fig. 3. The stress singularity is truncated by yielding at the

crack tip. When the yielding occurs, the plastic zone radius

r

p

became twice as large as

r

y

.

In plane strain yielding is suppressed by the triaxial stress state, and the Irwin plastic

zone is smaller by a factor 3.

The effective crack length is defined as the sum of the actual crack size

a

and plastic

zone correction

r

y

a

eff

=

a

+

r

y

(2)

The nonlinear material deformation is limited to a small region around the crack tip in

linear elastic fracture mechanics (LEFM). In elastic-plastic fracture mechanics (EPFM)

material exhibits time independent, nonlinear behaviour (i.e. plastic deformation).

Wells noticed that crack faces moved apart prior to fracture /3/. Plastic deformation

had blunted an initially sharp crack, Fig. 4. The blunting level is strongly dependent on

the toughness of the material. This observation led Wells to suggest that the crack tip ope-