177

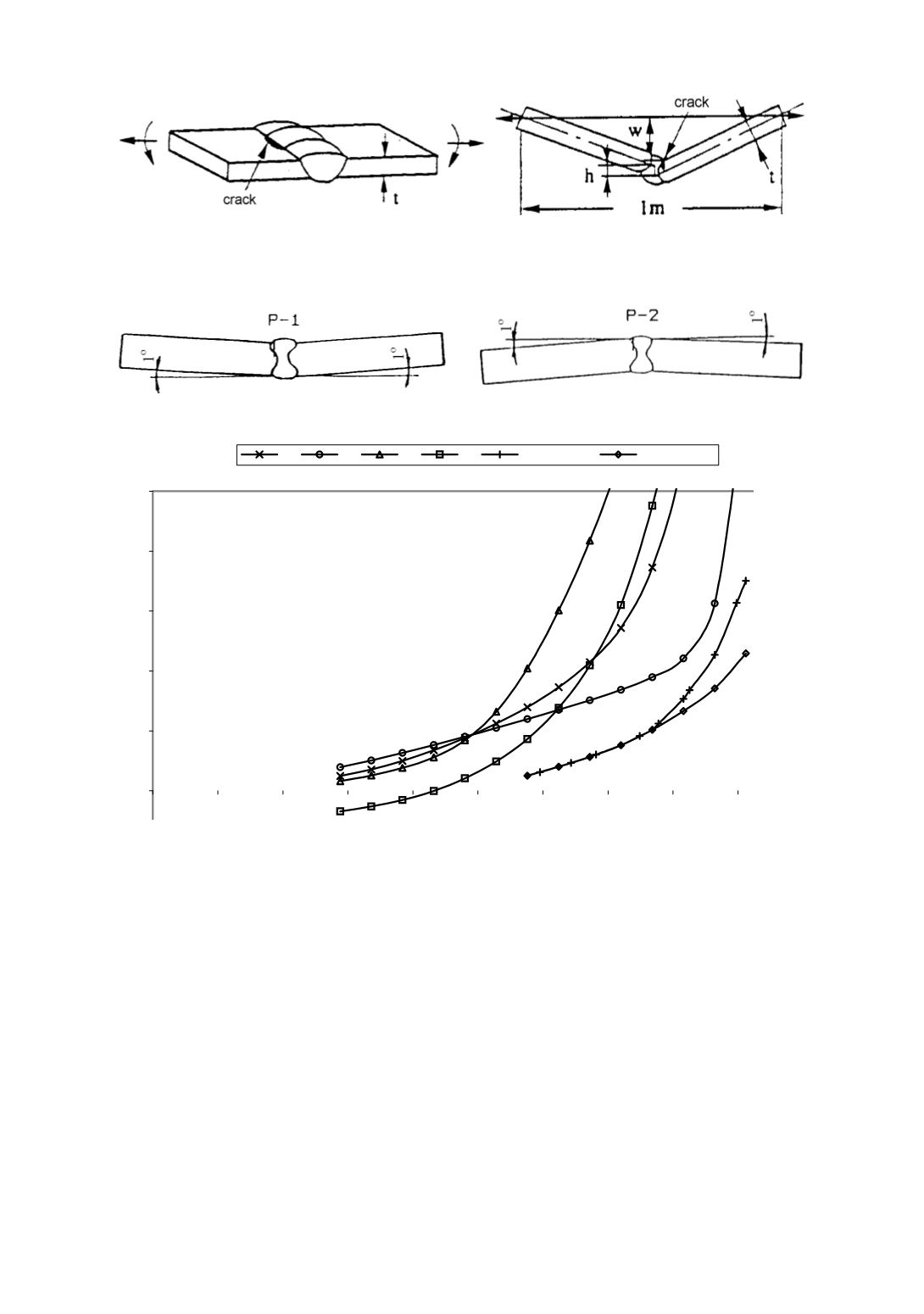

a. weld overlap b. misalignment

Figure 14: Crack occurrence due to stress concentration from defects in butt welds

Figure 15: Effect of angular distortion

0

20

40

60

80

100

0

50

100

150

200

250

300

350

400

450

J(N/mm)

P1

P2

P3

P4

c/t=0.45_REI1

c/t=0.45_REI0

σ

, MPa

Figure 16: Comparison of experimental results and results obtained by REI method.

Results obtained by REI method are given in two variants, the first one by an original

procedure REI0, and the other by modified variant REI1, where the yield condition is

replaced by a condition used in the King model /19/. Since it is not possible to consider

residual stresses and geometry imperfections in the REI method, results presented in Fig.16

clearly show that the best agreement is obtained for plate P2, and that the modified REI1

model variant exhibited better agreement than the original procedure REI0.

ACKNOWLEDGEMENT

This lecture contains a part of results obtained in the project 14014 “Research and

development methods for estimate integrity and reliability of welded pipelines in oil

industry” supported by Ministry of Science and Technological Development of Serbia.

REFERENCES

1.

The Pressure Equipment Directive (97/23/EC), on Internet