181

ning displacement (CTOD) can serve as a measure of fracture toughness, expressed in the

form of finite displacement

δ

at the crack tip.

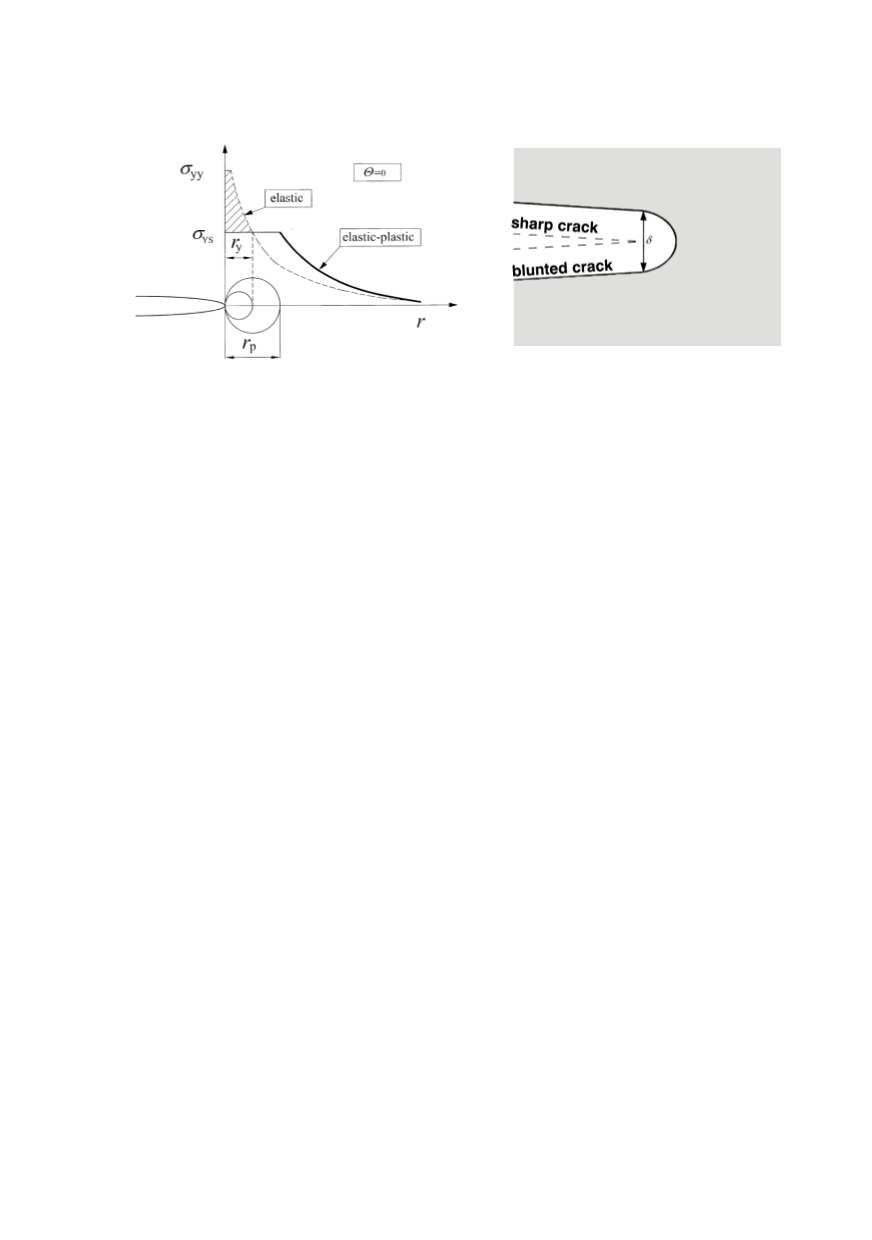

Figure 3. First order and second order estimates of plastic

zone size (

r

y

and

r

p

, respectively) /4/

Figure 4. Initially sharp crack blunts

by plastic deformation, resulting in a

finite displacement (

δ

) at the crack tip

4. STRETCH ZONE

In linear-elastic fracture-toughness testing crack initiation is easy to detect because of

its brittle nature. In contrast, a crack in a ductile material will first blunt, extend virtually,

and then grow continuously in a stable manner, Fig. 5, exhibiting different stages of crack

extension in a ductile material. The effect of described behaviour on crack resistance cur-

ve (J-R curve) for ductile material is presented schematically in Fig. 6 by the change of J

integral with crack extension. The R curve is nearly vertical in the first phase of deforma-

tion and there is a small amount of apparent crack growth due to blunting. As J increases,

the material at the crack tip fails locally allowing the crack to advance further. Because

the R curve is rising, the initial crack growth is usually stable. Some experience is neces-

sary to determine the crack-initiation toughness in elastic plastic materials, as there is no

straightforward procedure for evaluating a single correct ductile fracture toughness value.

Before stable tearing, virtual crack extension in ductile materials leaves a signature of

the crack-initiation and blunting phenomena called the stretch zone. This featureless re-

gion lies between the fatigue precrack front and the onset of ductile tearing, Fig 7 /5/. The

formation, shape, and size of the stretch zone are characteristics of the material /6, 7/. In

highly ductile materials, the stretch zone would normally have two components: a

horizontal component called the stretch-zone width (SZW) and a vertical relief of the

crack front called the stretch-zone depth (SZD), as depicted in Fig. 8. Both the SZW and

SZD are closely related to the fracture toughness of a ductile material, and many attempts

have been made to measure the characteristic stretch-zone parameters on the fracture

surface of specimens and use them as an aid in determining the critical fracture tough-

ness. The measured SZW or SZD values can be used as convenient indicators for

identifying the crack initiation point on the experimentally generated crack-growth-resist-

ance (R) curve. There is no consensus among researchers whether ductile fracture tough-

ness should be estimated using SZW or SZD. Some of them use the SZW, while others

argue that SZD measurement is more appropriate than SZW for obtaining fracture tough-

ness of ductile materials /8/.

An advantage of SZW is that it can be measured directly on the specimen fractured

surface using a scanning electron microscope (SEM), whereas SZD measurements are