172

Dead weight of vessel (4400 kg) is used at elevation of empty tank by shrouds under

the angle of 45

°

, item 10.

Allowable deformations and stresses

The highest allowable deformation is defined by the request that applied loadings must

not produce permanent deformation, according to selected material of the vessel, fine

grained structural steel TStE355, Table 1.

Table 1: Mechanical characteristics of TStE355 steel

Young modulus Yield strength Tensile strength

Elongation

Impact toughness, J, at

E

, MPa

R

eH

, MPa

R

m

, MPa

L

o

= 5

d

, %

-20

°

C

-50

°

C

200000

414 - 436

574 - 582

28-30

176-200

50-53

For adopted safety factor

S

= 1.1 allowable stress

σ

al

and elongation

l

al

are:

σ

al

=

R

eH

/

S

= 414 / 1.1 = 376 MPa

l

al

=

σ

al

x L/

E

=376X835.7/ 200000 = 15.7 mm

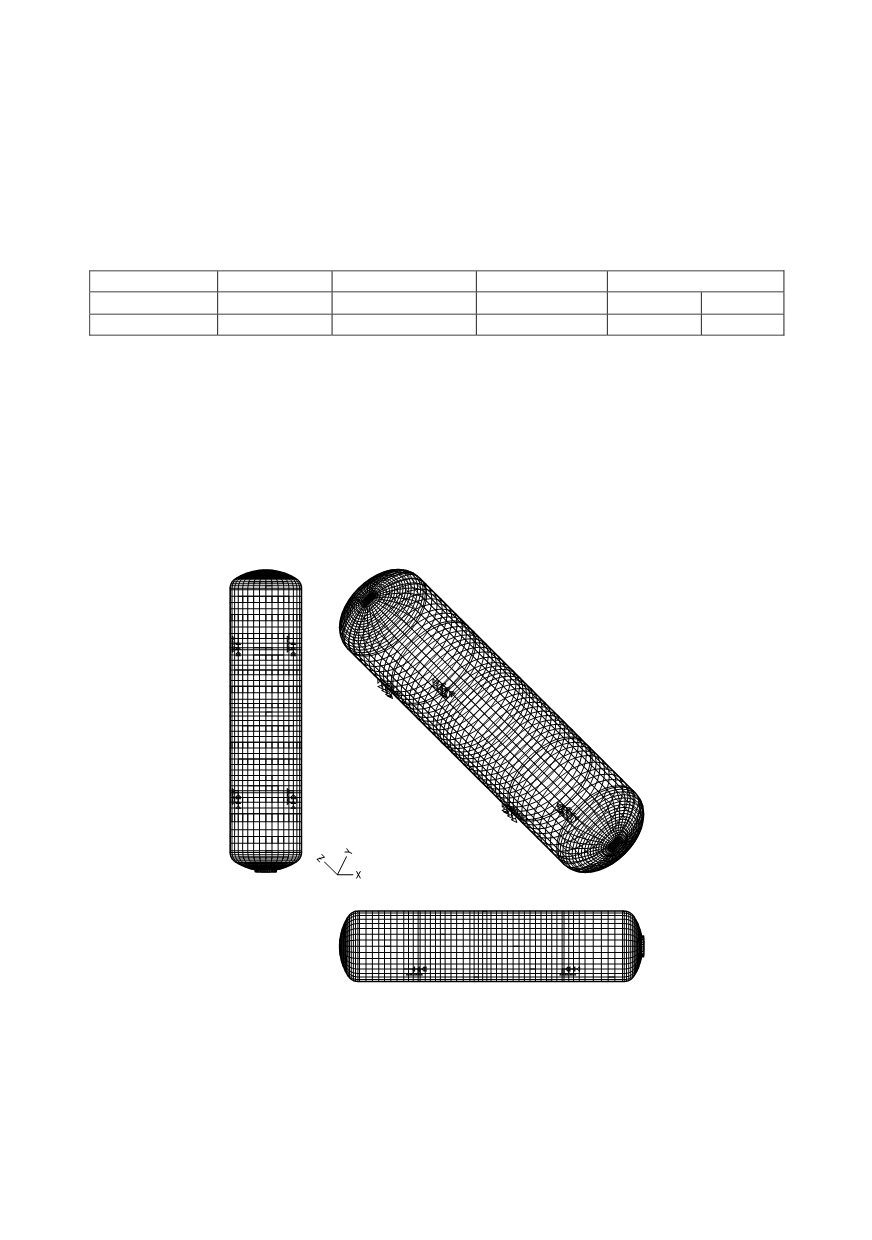

Model of tank structure

Strength calculation is made by finite element method (FEM) in KOMIPS program.

In static calculation tank is considered as a space structure of connected plates

elements (quadratic and triangular) with variable cross section. The whole bearing struc-

ture is reduced to middle plane of shell and front and rear lids. All the connections are

reduced to one of considered planes. Accepted model, Fig. 9, consisted of 3242 nodes and

3308 plate elements /13/. This calculation is used to derive requested conclusions.

Figure 9: Accepted finite elements model of tank used for calculation

For plate elements, maximum equivalent stresses and strains in considered section

have been calculated using suitable software modules. Displacements of the nodes for

typical and critical loadings by mass of vessel and the mass of working and test fluid are

shown in Fig. 10, with stresses calculated from strains.