164

rements to be fulfilled by design, manufacturing and compatibility assessment of pressure

equipment and components for maximal allowed pressure above 0.5 bar.

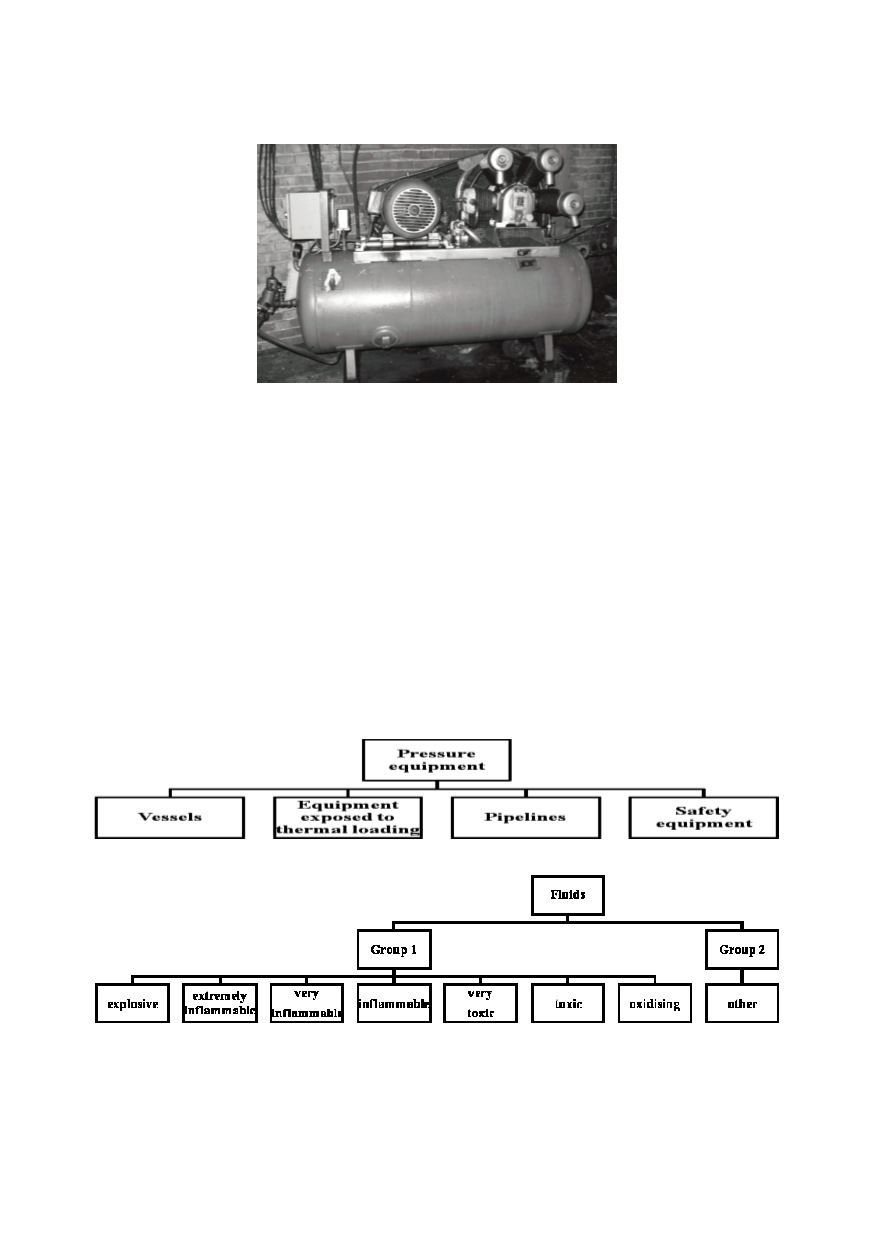

Figure 1: Compressor unit

In order to define the usage of the Directive to particular components of pressure

equipment, manufacturer has to classify the equipment for evaluating the compatibility

into one of the four categories (I – IV). The first category is concerned with the smallest,

and the fourth category to the greatest danger of pressure /1, 3/.

The equipment with parameters beyond the first category is subject of the existing

engineering practice and is not evaluated for compatibility.

To define category of pressure equipment, manufacturer should identify:

–

category

of

equipment - vessel/steam generator/pipeline/safety equipment, Fig. 2;

–

phase of fluid in the equipment

-

gas or liquid;

–

group of fluid in the equipment

-

group 1 or group 2

,

Fig. 3.

Group 1 covers the fluids which are, according to EC Directive for classifying

dangerous substances, marked as: explosive, extremely flammable, very flammable,

flammable (with the maximum allowed temperature above the ignition point), very

poisonous, poisonous, oxidising. Group 2 covers all other fluids, including water/steam.

Figure 2: Categorization of pressure equipment

Figure 3: Subdivision of fluids

Directive demands that all the pressure equipment and assembles be safe when putting

them on the market and applied in service. The basic safety requirements and certificates

are not requested for the group of the accepted engineering practice (EP).