92

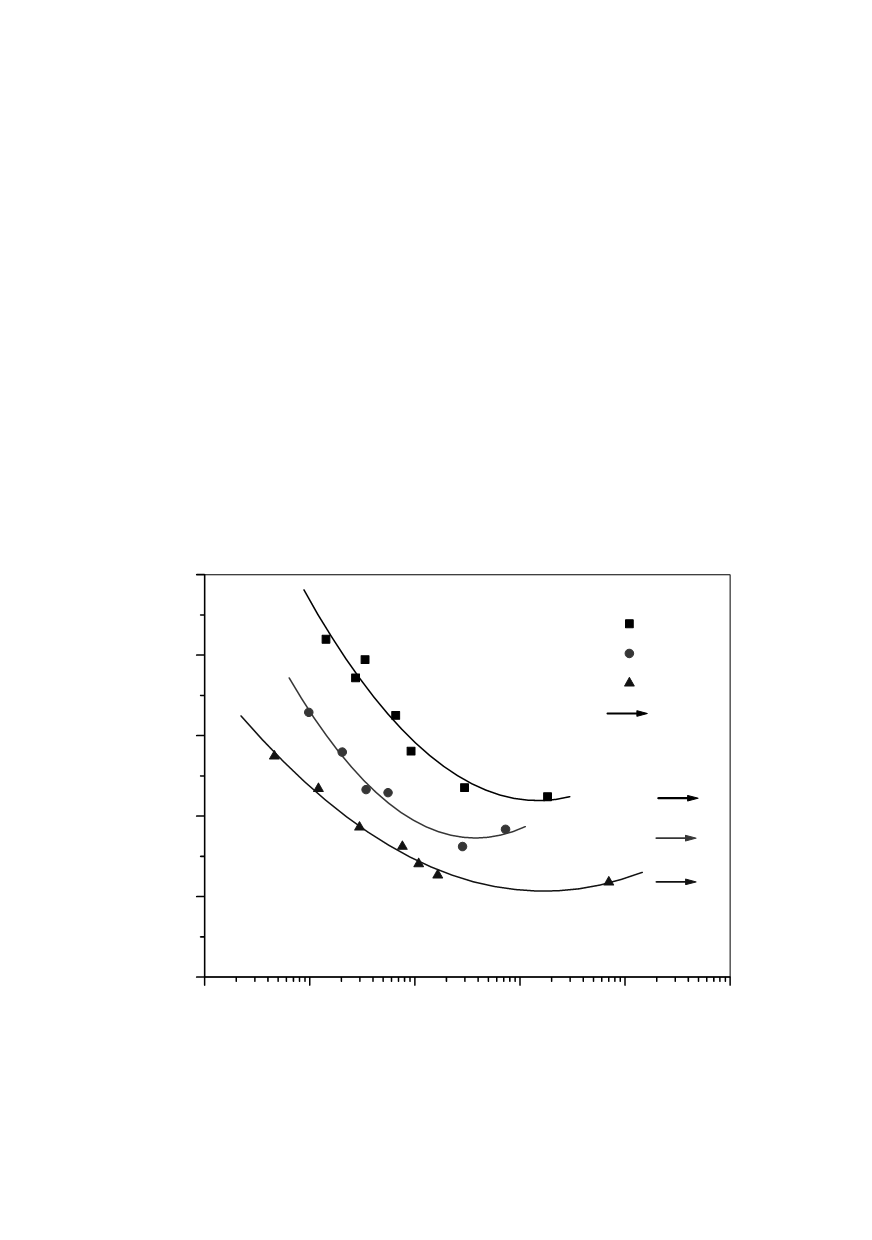

Other examples of metallic response to cyclic loading in this regime are also interes-

ting, like the behaviour of an aluminum alloy 2219-T85 (Fig. 5), showing a

S

max

versus

log

N

plot, with the supporting data shown /12/. This is a typical S-N diagram, showing

the fitted curve as the actual data that support the diagram. This is the currently required

approach for representing this type of information in the handbook /12/.

Plastics and polymeric composites are interesting materials for different responses un-

der mechanical loading, including dynamic excitation. The nature of hydrocarbon bon-

ding results in substantially more hysteresis losses under cyclic loading and a greater

susceptibility to frequency effects. An example of

S

-

N

results for a variety of materials is

given in Fig. 6. Also, different specifications are used for fatigue testing of plastics /13/.

The plastics industry also employs tests to determine a "static" fatigue response, which is

a sustained load test similar to a stress-rupture or creep test of metallic materials.

In application, this method is in its simplest form for steels in a neutral environment.

The task is to compare the

S

a

determined in the part to a

S

a

vs.

N

curve at the necessary

R

value. Acceptable safe-life, infinite-life situation exists if the applied

S

a

is less than the

fatigue limit. In a slightly more complex scenario, the

S

m

, S

a

pair applied in a component

is compared to the properly determined Goodman line on a Haigh diagram with two

possible results: on or under the Goodman line indicate an acceptable safe-life, infinite-

life situation, and results above the Goodman line indicate a finite-life situation that can

be managed if the general boundary conditions of the method are not abused.

10

3

10

4

10

5

10

6

10

7

10

8

0

100

200

300

400

500

Stresses are based

on net section

Stress ratio

0.500

0.050

-0.500

Runout

Maximum stress, MPa

Fatigue life, cycles

Figure 5: Best-fit S/N curves for notched, 2219-T851 aluminium alloy plate in longitudinal

direction, with stress concentration factor

K

t

= 2.0