72

incorporated into Eq. (7). The influence of the mean stress

σ

m

on the plastic flow of the

material is another important property of the Gurson criterion.

3.1. Gurson-Tvergaard-Needleman model (GTN)

Thomason /12/ and Tvergaard /13/ have shown that Gurson yield criterion can capture

the influence of the voids on the material damage during the early stage of ductile fracture

(growth of voids), but the results deviate from the experimental ones with the increase of

the external loading. To improve the material behaviour assessment in the final stage of

fracture, Tvergaard /13/ modified the original Eq. (1), introducing two parameters of the

constitutive model,

q

1

≥

1 and

q

2

≥

1, into the parts containing the void volume fraction

f

and mean stress

σ

m

. Also, the yield stress is replaced by the current yield stress of the

material matrix

σ

, to take the material hardening into account. The basic equation of the

Gurson-Tvergaard-Needleman model (GTN) is:

(

)

2

*

*

2

1

1

2

3

3

2 cosh

1

0

2

2

ij ij

m

S S

q

f q

q f

σ

φ

σ

σ

⎛

⎞ ⎡

⎤

=

+

− +

=

⎜

⎟ ⎢

⎥

⎣

⎦

⎝

⎠

(8)

where

f*

is so-called damage function, proposed by Tvergaard and Needleman /14/:

for

*

(

) for

c

c

c

c

f

f f

f

f

K f f

f

f

≤

⎧

= ⎨ + −

>

⎩

(9)

f

c

is the critical void volume fraction, corresponding to the initiation of their coalescence,

and

K

is parameter that represents the loss of load-carrying capacity of the material

(sudden drop of force at the force - diameter reduction diagram):

*

u c

F c

f

f

K

f

f

−

=

−

(10)

Void volume fraction at final fracture is denoted as

f

F

, while

*

1

1

u

f

q

=

is the value of

damage function at the moment of fracture.

Parameters

q

1

and

q

2

intensify the influence of

f

and

σ

m

on the plastic flow of the

material, favouring the development of damage, especially for large values of triaxiality

and porosity. Tvergaard /13/ proposed the values

q

1

= 1.5 and

q

2

= 1, as the values most

suitable for high-strength steels.

Gurson-Tvergaard-Needleman model was used for analysis of ductile fracture of

various metallic materials; e.g. pressure vessel steel by Rakin et al. /15, 16/, welded joints

by Rakin et al. /17/ and Dobrojević et al. /18/.

Gao et al. /19/ analysed the influence of the yield strain and hardening exponent on the

parameters

q

1

and

q

2

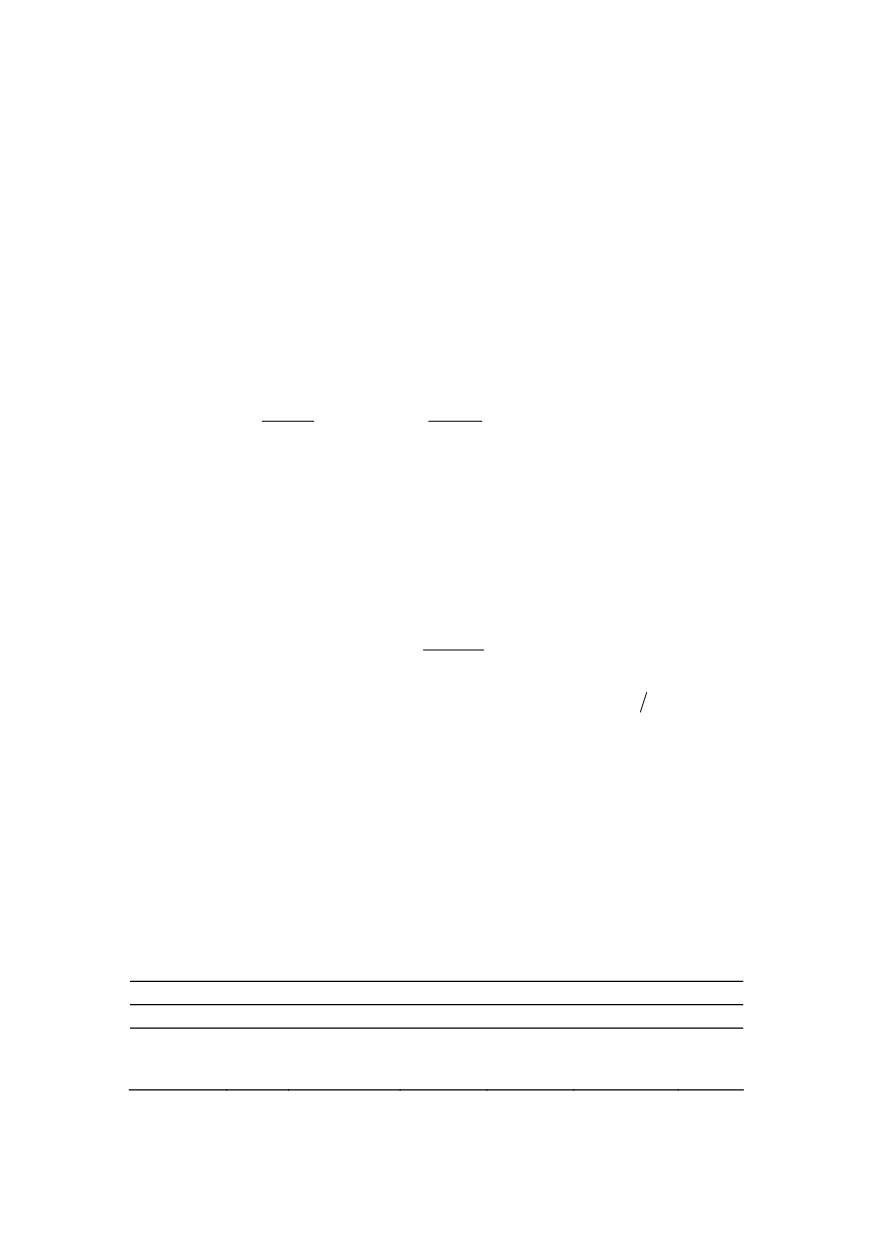

for Cr-Mo pressure vessel steel. Their results are given in Table 1.

Table 1: Values of

q

1

and

q

2

, depending on the hardening exponent

n

and ratio

σ

Y

/

E

/19/

σ

Y

/

E

= 0.001

σ

Y

/

E

= 0.002

σ

Y

/

E

= 0.004

n

q

1

q

2

q

1

q

2

q

1

q

2

5

1.96

0.781

1.87

0.800

1.71

0.836

6.7

1.78

0.833

1.68

0.856

1.49

0.901

10

1.58

0.902

1.46

0.931

1.29

0.982