69

MICROMECHANICAL CONSTITUTIVE EQUATIONS FOR

DUCTILE FRACTURE PREDICTION

Marko Rakin

University of Belgrade, Faculty of Technology and Metallurgy, Belgrade, Serbia

marko@tmf.bg.ac.yuBojan Međo

University of Belgrade, Faculty of Technology and Metallurgy, Belgrade, Serbia

1. INTRODUCTION

Ductile fracture mechanism in metallic materials develops through three stages -

nucleation of voids, their growth and eventual coalescence. This mechanism is

characterised by a local development of damage, hence it does not depend on the

analysed geometry. There are two main mechanisms of void nucleation in metallic

materials: particle cracking and debonding from the metallic matrix. The void existence

in the material causes local stress and strain concentration in the surrounding matrix.

Under the external loading, the void changes its shape and volume (void growth stage),

which makes the analysis of the above-mentioned fields very complicated.

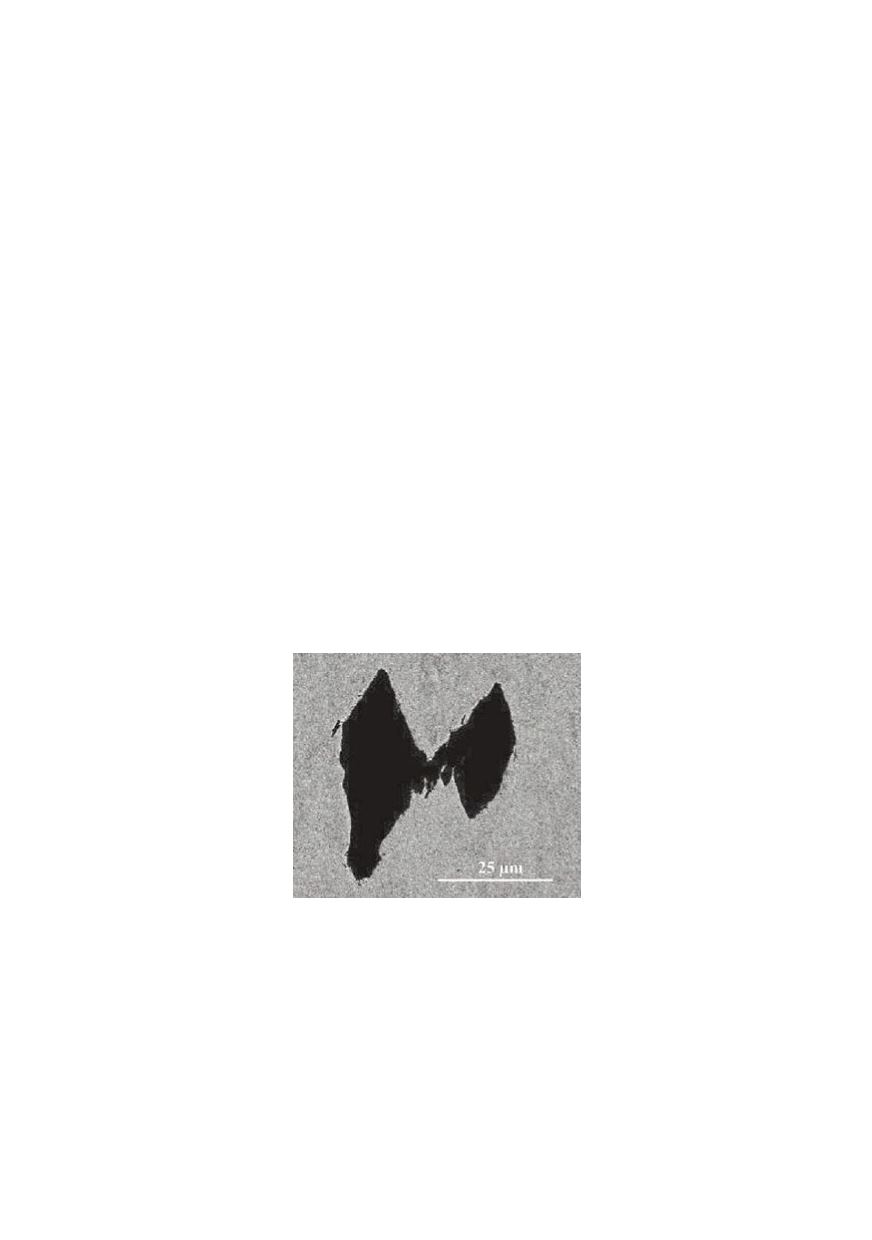

Void coalescence occurs during the localization of the plastic deformation on

microscopic level - in the intervoid ligaments. The plane of localization depends on the

orientation of the ligament between two voids with respect to the loading direction. An

example of void coalescence, in steel A508, is given in Fig. 1.

Figure 1: Void coalescence in steel A508 /1/

Elastic-plastic fracture mechanics (EPFM) cannot reliably describe the complex

process of ductile fracture in metallic materials. Therefore, parameters that reflect the

local nature of damage process should be introduced. Local approach uses such

parameters, and is able to describe the fracture process in a way close to the actual

phenomena in the material. It is based on micromechanical models of microscopic

damage, with the aim to explain and predict the macroscopic failure of structure.

The correct use of the micromechanical models should include a close interaction of

microstructural examination, material characterisation, fracture mechanics testing and

numerical calculations. Having in mind that the parameters used for damage