77

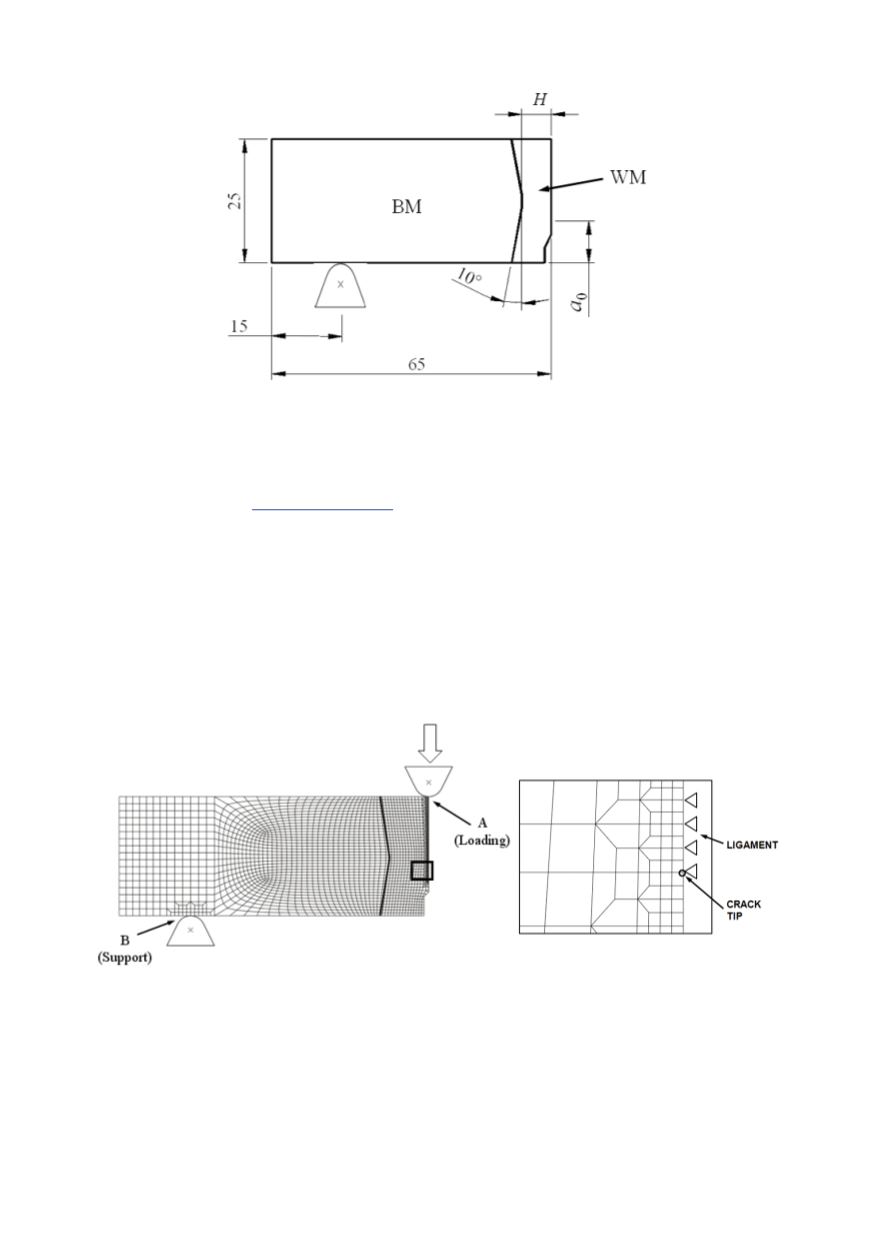

Figure 5: Dimensions of the SENB specimen and weld metal (2

H

= 6, 12 and 18 mm)

The specimen is analysed under plane strain conditions, and the finite element (FE)

mesh is shown in Fig. 6, with magnification of the region near the crack tip. Crack tip is

modelled using a refined FE mesh without singular elements. Finite element software

package ABAQUS (

www.simulia.com )is used for numerical analysis, and the CGM is

applied through user material subroutine created by Zhang, based on /21/. The initial void

volume fraction

f

0

is set as equal to

f

v

, according to /25, 36/. FE calculations are carried

out with the values of Tvergaard constitutive parameters

q

1

= 1.5 and

q

2

= 1. External

loading is defined by prescribing displacement of the rigid body, which is in contact with

the model (position A, Fig. 6). Contact is also used for defining the boundary conditions

for support (position B). It is important to note that the heat affected zone (HAZ) is not

taken into account, based on /37, 38/, since the crack is located in the weld metal, along

the axis of symmetry of the joint. Coupled approach to ductile fracture (the GTN model)

was also used in /17, 18/ for assessment of ductile fracture initiation in these joints.

Figure 6: FE mesh of one half of SENB specimen (left) and detail around the crack tip (right)

5.3. Crack growth initiation

Distribution of void volume fraction

f

near the crack tip at the crack growth initiation

is shown in Fig. 7 for the joint 6 mm wide and 20-node elements with reduced integration

and size 0.15x0.15 mm. Concentration of large values very close to the crack tip is

obvious. One can also see a large variation of

f

in the elements near the crack tip.