76

E1245-89 standard and /34/), by quantitative microstructural analysis using optical

microscope, based on the equality with surface fraction of detected inclusions

A

A

/34/:

i

v

A

T

A

f = A =

A

(19)

where

A

i

is the area of inclusions and

A

T

is the measurement field area.

For determining the mean free path between non-metallic inclusions

λ

according to

ASTM E1245-89 standard, in each measurement field five horizontal measuring lines are

drawn, and the number of interceptions of inclusions per measurement line unit,

N

L

, is

determined. The mean free path is mean edge-to-edge distance between inclusions:

1

A

L

A

N

λ

−

=

(20)

The final value of

λ

is determined, in the same way as the volume fraction of non-

metallic inclusions

f

v

, as the mean value for all measurement fields.

The values of

f

v

and

λ

for both materials are given in Table 3.

0.0

0.2

0.4

0.6

0.8

1.0

0

200

400

600

800

1000

1200

1400

WM:

E

= 183.8 GPa

R

P

0.2

= 648 MPa

R

m

= 744 MPa

BM

OM

ε

BM:

E

= 202.9 GPa

R

P

0.2

= 545 MPa

R

m

= 648 MPa

σ

[MPa]

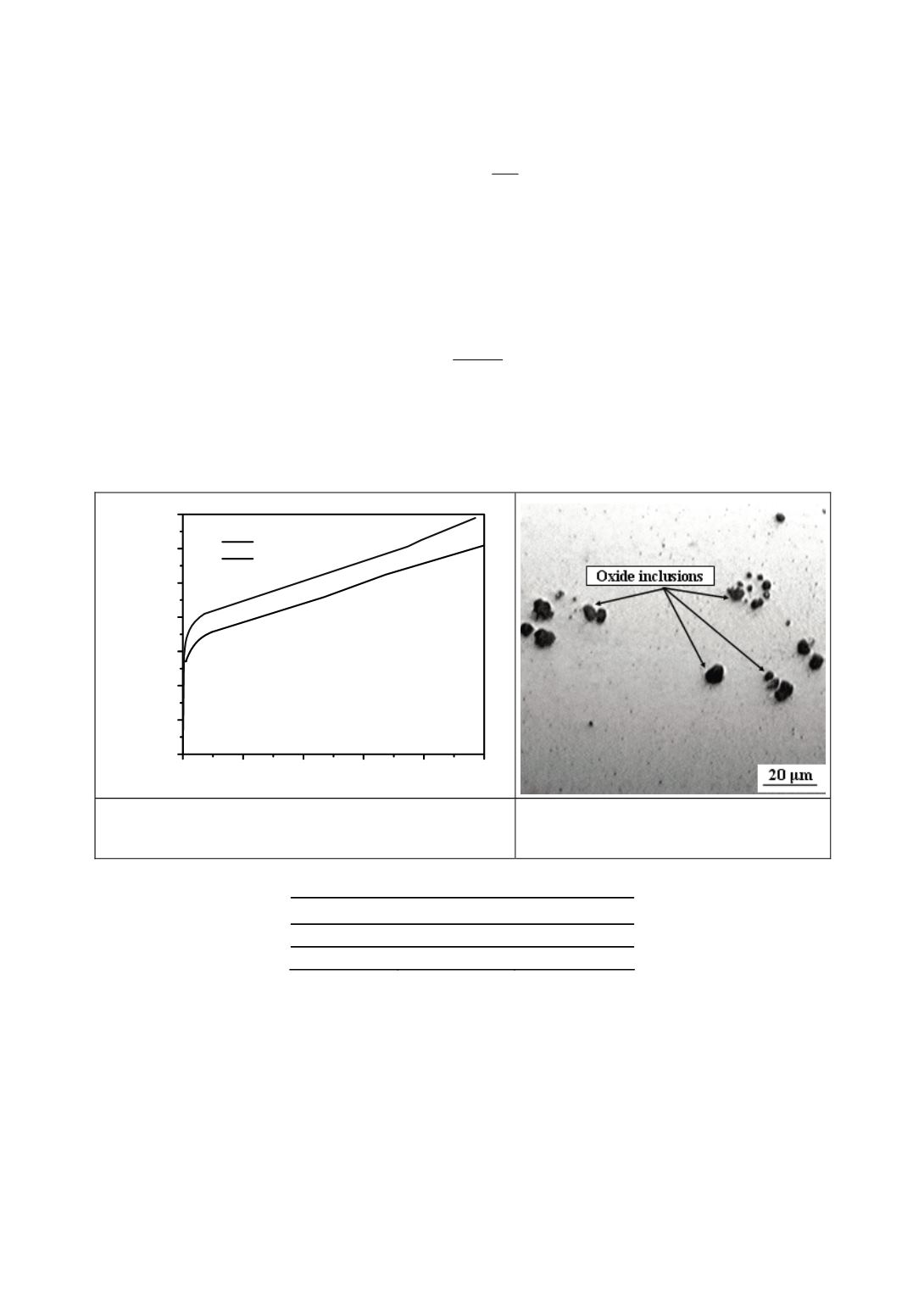

Figure 3. Tensile properties and true stress - true strain

curves of BM and WM at room temperature

Figure 4. Microphotograph of oxides in

base metal

Table 3: Volume fraction

f

v

and mean free path between non-metallic inclusions

λ

Material

f

v

λ [µm]

BM

0.012164

103.1336

WM

0.006342

157.4719

5.2. Finite element model

Single-edge notched bend (SENB) specimens are used for examination of the welded

joints, with different width of WM (and joint) 2

H

: 6, 12 and 18 mm, Fig. 5. Crack tip

opening displacement (CTOD) values are determined, both experimentally and by

numerical calculations, using

δ

5

concept /35/.