26

2

1

6

eff

y

YS

K

r

π σ

⎛

⎞

= ⎜

⎟

⎝

⎠

(12)

Calculation of

K

eff

is iterative process that, however, very fast leads to the end values.

The correction is in reality also dependent on material hardening (

n

) and geometry.

In fact, calculation process in LEFM is the same, independent on plane stress or strain

conditions (or between), but the toughness values (that must be evaluated experimentally)

are higher if the conditions are not plane strain. This increase is accompanied with

sometimes large errors, and it is better to use the

K

Ic

values. Methods of LEFM meet the

limits if the stress is higher than the half of yield strength. It should be recognize that the

calculation results are more and more on the unsafe side.

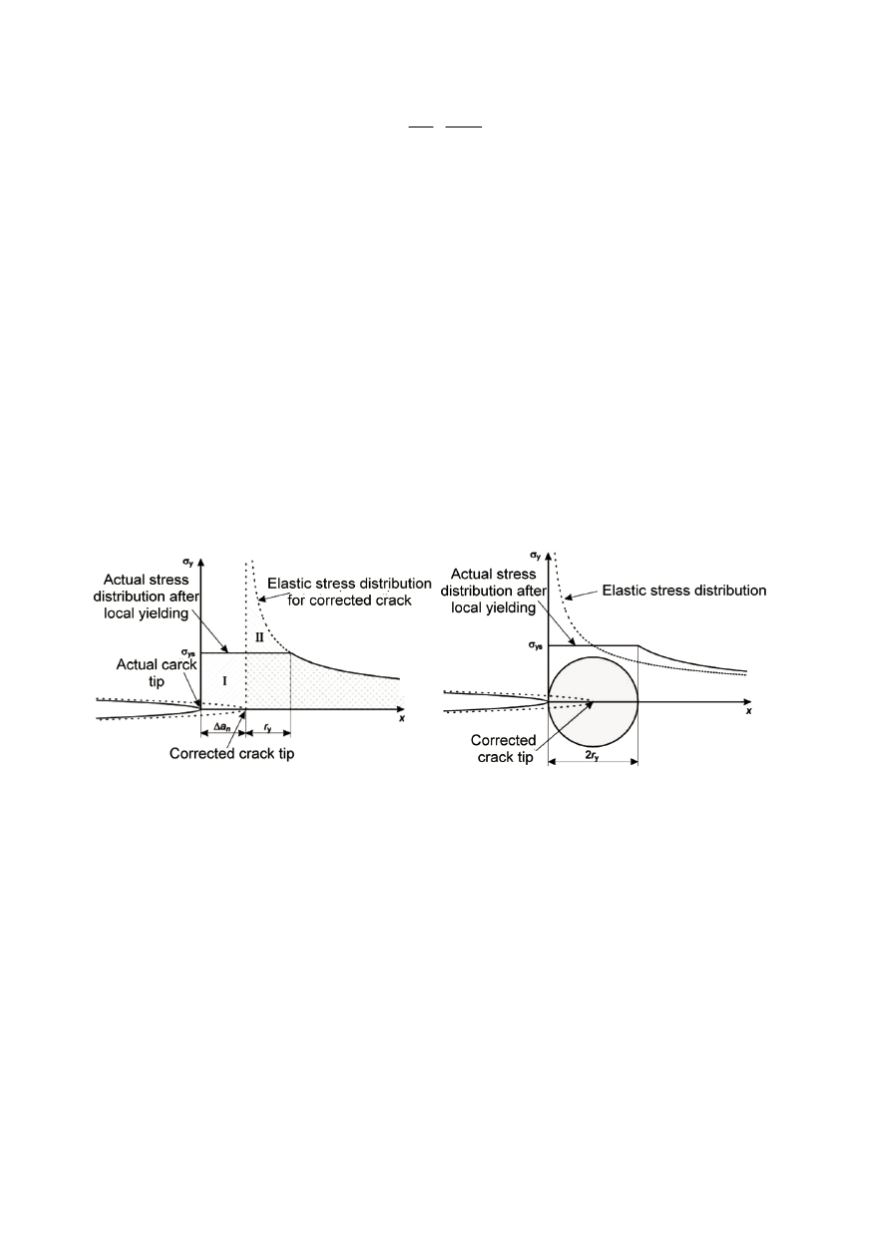

Corresponding relationships and mechanisms can be explained graphically in a simple

way using stress-strain diagram for specimen with the crack (Fig. 8). It is not difficult to

note that because of additional plastic deformations the amount of energy spent is larger.

Physical mechanisms of energy dissipation are based on plastic deformation in the

vicinity of crack tip for metals, micro cracks for ceramics, fibre pull-out for composites

and even on the basis of material heating and/or on all that. For that, convincing energy

ends to be only crack surface energy

G = dWdA

as in the case of LEFM conditions. In

plastic deformations, as known, not only crack tip but also the volume near to the tip or

even near to the all net section take part, and this must be considered (

dWdV

).

Figure 7. Irwin’s correction for the plastic zone

As already accentuated, introduced energy is not only spent on crack growth and

fracture. Total energy after loading to the point (P, Fig. 8) corresponds to the area under

the curved (OPS). The energy amount

(dWdV)

p

spent for the plastic deformation become

visible only after unloading, in which the remain recoverable part of energy is released

(dWdV),

that is lower than the total energy. It corresponds to the triangle UPS. It is to

note that unloading path slope of crack extension differs from the initial one. This appears

as the consequence of reduced stiffness due to the net section area reduction. At failure,

assumed in point F, only the recoverable energy is available and, therefore, relevant as the

measure of the failure resistance. It is directly related to the

J

-integral and

G

. However,

this energy cannot be measured in this way, because the specimen is broken.

In LEFM conditions energy release rate

G

is proportional to

K,

as given in Eq. (3).

This is not valid for ductile materials, and in EPFM other parameters are necessary.

There are two main development branches in EPFM: crack tip opening displacement

(CTOD,

δ

), popular in Great Britain and Europe, and

J

-integral, from the beginning