21

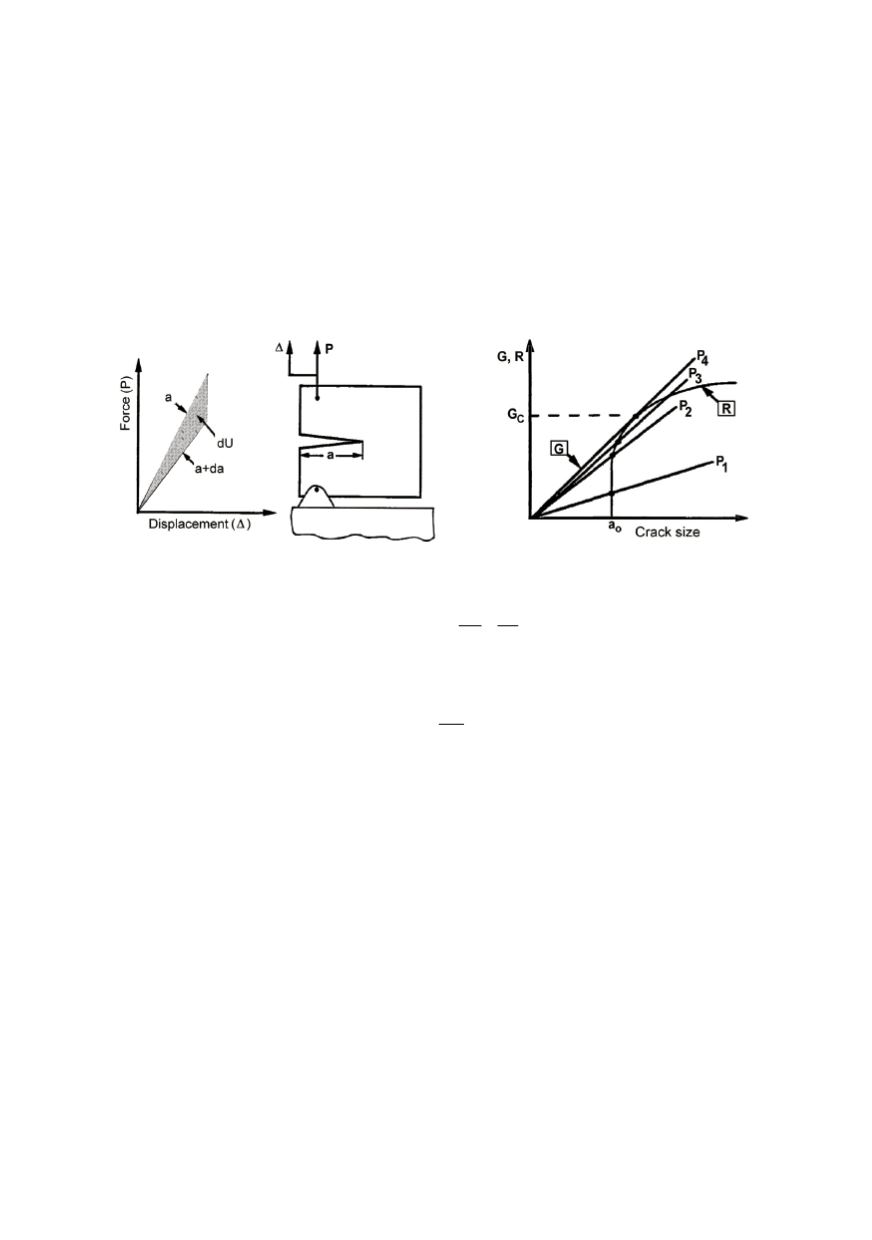

If the driving force

G

is larger than material resistance

R

, the crack growth becomes

unstable. If

G = R

the crack growth can be stable or unstable, that depends on material

and loading configuration, i.e. the way how

G

changes with the crack growth. This

behaviour is described using so called resistance curve (

R

-curve, Fig. 2). The driving

force is presented by a series of

G

versus crack length lines for various load levels. Most

materials have the resistance curve

R

that grows depending on the crack size increase. In

this case, up the loading increase at to the

P

2

level nothing happens, because the material

resistance is larger than the driving force. Only when the loading reaches

P

3

level, the

crack grows for a small amount in accordance to the resistance curve curvature. When the

load reaches

P

4

the unstable situation is established. Because the material resistance is not

sufficient to prevent it, the crack continuously grows, frequently up to final fracture.

Figure 1. Condition for crack growth

Figure 2. Scheme of (un)stable crack growth

In accordance to it one can write:

and

dG dR

G R

da da

=

≤

(2)

At the same time, Irwin showed that for these conditions the equivalent relationship

exists between energy and stress intensity factor

K

for linear elastic materials.

2

'

KG

E

=

(3)

where

E' = E

(Young’s modulus) for plane stress and

E’ = E/(l -

v

2

)

for plane strain;

ν

is

Poisson’s ratio. Anyhow, the stress intensity approach is commonly applied in LEFM.

2.2. Elastic-plastic features of the material

Inelastic strains appear in the material on the basis of dislocations. Inelastic deforma-

tions are of irreversible character. The rules based on the classic plasticity theory decom-

pose total deformation to elastic and plastic parts with corresponding relationship for each

of them. The total strain is the sum of its elastic and plastic components:

ε

=

ε

e

+

ε

p

(4)

Classic plasticity theory is based on following elements:

–

A yield surface defining elastic limit of a material in a multiaxial stress state that

defines if the body will react in elastic or plastic way (Fig. 3).

–

A hardening rule that defines material behaviour during yielding, i.e. the way in which

the resistance to the plastic strain grows together with inelastic strains.

–

A flow rule defining the magnitude and direction of the plastic strain development.

–

Elastic unloading criteria that models irreversible features of the body.