23

frequently used. Although here is not plastic material considered, if the loading is

proportional, the incremental and deformation theories produce the same results.

2.3. Micro mechanisms of fracture

For the application of the fracture mechanics in general, and particularly for elastic-

plastic fracture mechanics, it is important to establish the difference between brittle and

ductile fractures. Modes of fracture in steel and in its welded joint are transgranural

cleavage, microvoid coalescence and intergranular fracture, or their combinations.

Cleavage is rapid, unstable fracture usually of brittle materials, and ductile tearing

(microvoid coalescence) occurs in a slow, stable manner. Intergranular cracking can be

ductile or brittle. It is usually associated with a corrosive environment, grain boundary

segregation, or both. The fracture toughness parameters depend on fracture mechanisms.

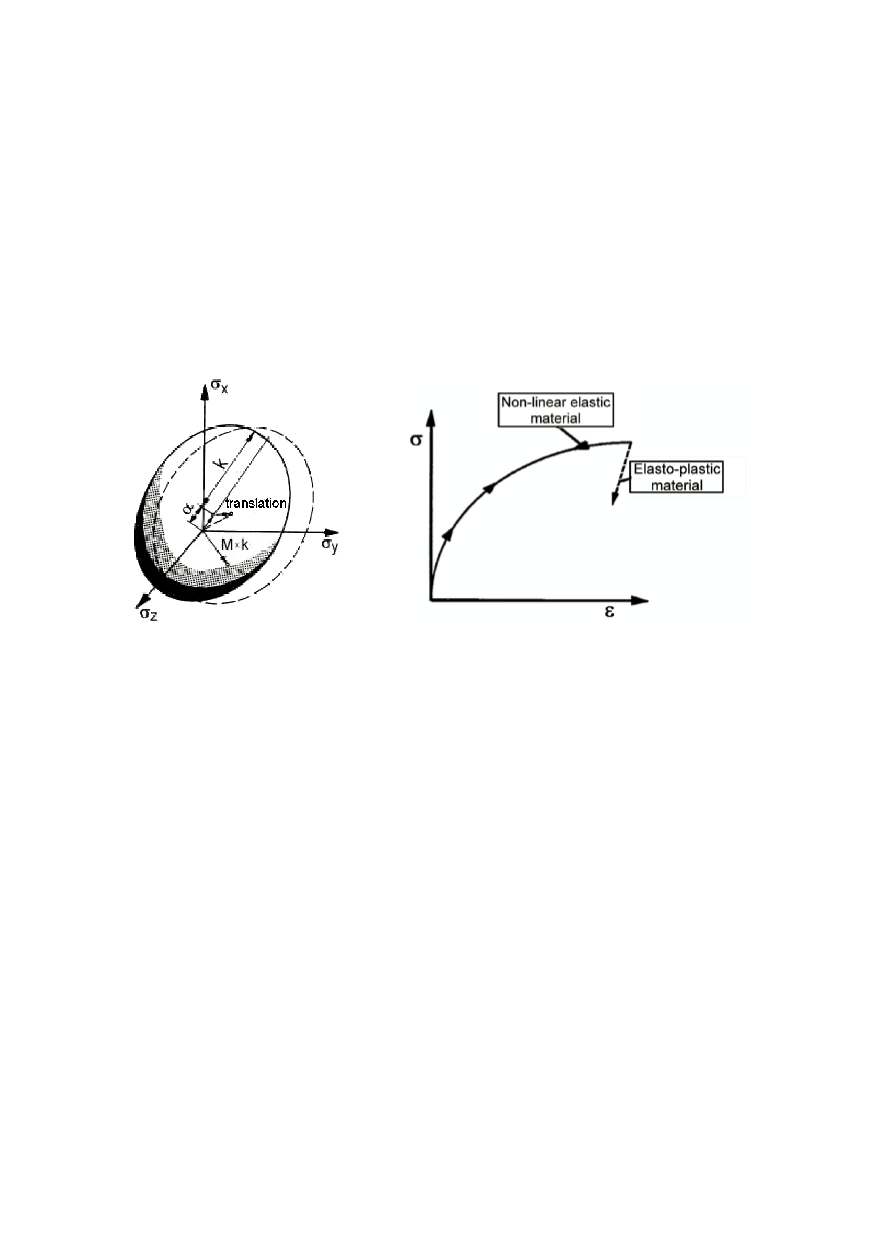

Figure 3. Yield surface

Figure 4. Elastic-plastic and non-linear elastic material

Brittle fracture takes place by rapid crack extension and negligible plastic defor-

mation, with even, flat fracture surfaces. For most brittle crystalline materials, crack

propagation corresponds to the successive breaking of atomistic bonds along well defined

crystallographic (or cleavage) planes (in case BCC iron it is 100). For fracture to occur,

the cohesive strength of material must be prevailed and the tearing occurred when the

local stress is high enough to drive micro crack to grow locally in microstructure, at

carbides or inclusions). Transgranular fracture means that the crack grows through the

grains, changed the direction from grain to grain, in dependence of the atomic orientation

in particular grains. It is logical that, when the crack reaches the boundary of the new

grain, it searches new direction of the lowest resistance for further growth.

The places in the microstructure where the tearing occurs depend on the alloy and heat

treatment. In mild steels cleavage usually initiates at grain boundary carbides. In

quenched and tempered steels critical places are spherical carbide or inclusion.

Susceptibility to

cleavage fracture is enhanced by almost any factor that increases the

yield strength, such as low temperature, a triaxial stress state, radiation damage, high

strain rate, and strain aging. In ferritic steals, cleavage occurred at low temperature, with

temperature increases the fracture become ductile, based on microvoid coalescence.

The growth of the ductile crack is accompanied with significant plastic deformation

and the ductile fracture reveals characteristic coarse fracture surface. The mechanism of

crack growth is shown in Fig. 5. At the beginning plastic deformations cause formation of

small micro cavities in material at inclusions. In the next process development the