32

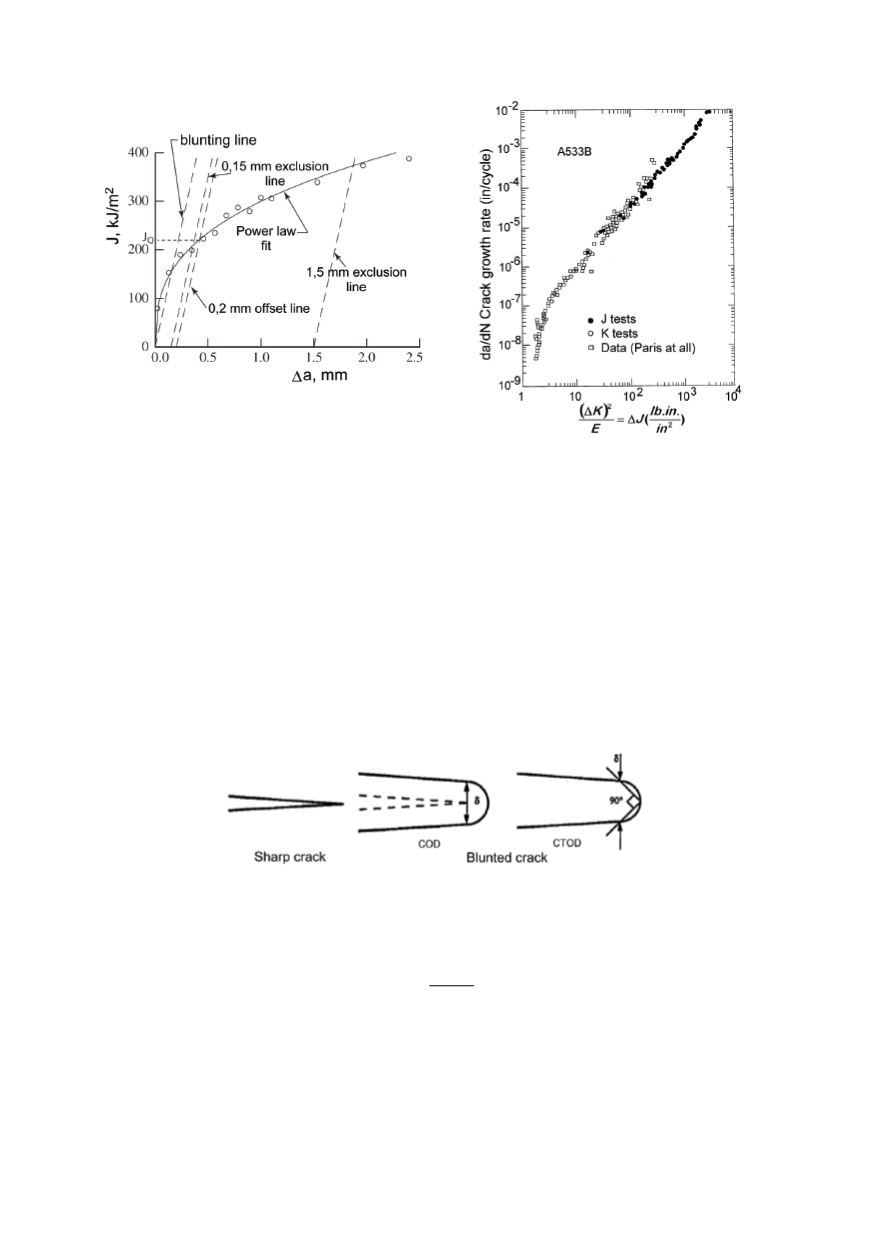

Figure 12.

J

-

R

curve evaluation based on test

results

Figure 13. Crack growth rate vs.

Δ

J

3.3. Crack opening displacement

In the late 1950s, Wells applied Irwin’s stress intensity concept to measure the fracture

resistance of medium strength structural steels, and found that they materials exhibited a

high degree of plastic deformation prior to fracture. This was good news for designers,

indicating high toughness in these steels, but was bad news for fracture mechanics

application because it meant that LEFM is not applicable to typical structural steels.

Wells noticed on tested specimens that the crack faces open strongly prior to fracture

so that this can be accurately measured. Based on these observations he proposed in 1961

crack opening displacement as a fracture toughness criteria. Crack opening displacement

(COD) was defined on its tip, Fig. 14. Today is usual to measure crack opening at

surfaces positioned at 90° at crack tip (CTOD). Both measurements give similar results.

Figure 14: Crack opening displacement (COD) and crack tip opening displacement (CTOD)

To verify the concept Wells showed that under the condition of plane stress and small

scale yielding between

K

I

and CTOD (

δ

) analytical dependence exists in form

2

I

YS

K

E

δ

σ

=

(24)

Although this parameter was intended for the application outside LEFM, it was

certainly useful to found it in accordance with the valid facture mechanics relationships.

Similarly the relationship between

J

and CTOD can also be established in form:

J

=

σ

YS

δ