294

Influence on recrystallization

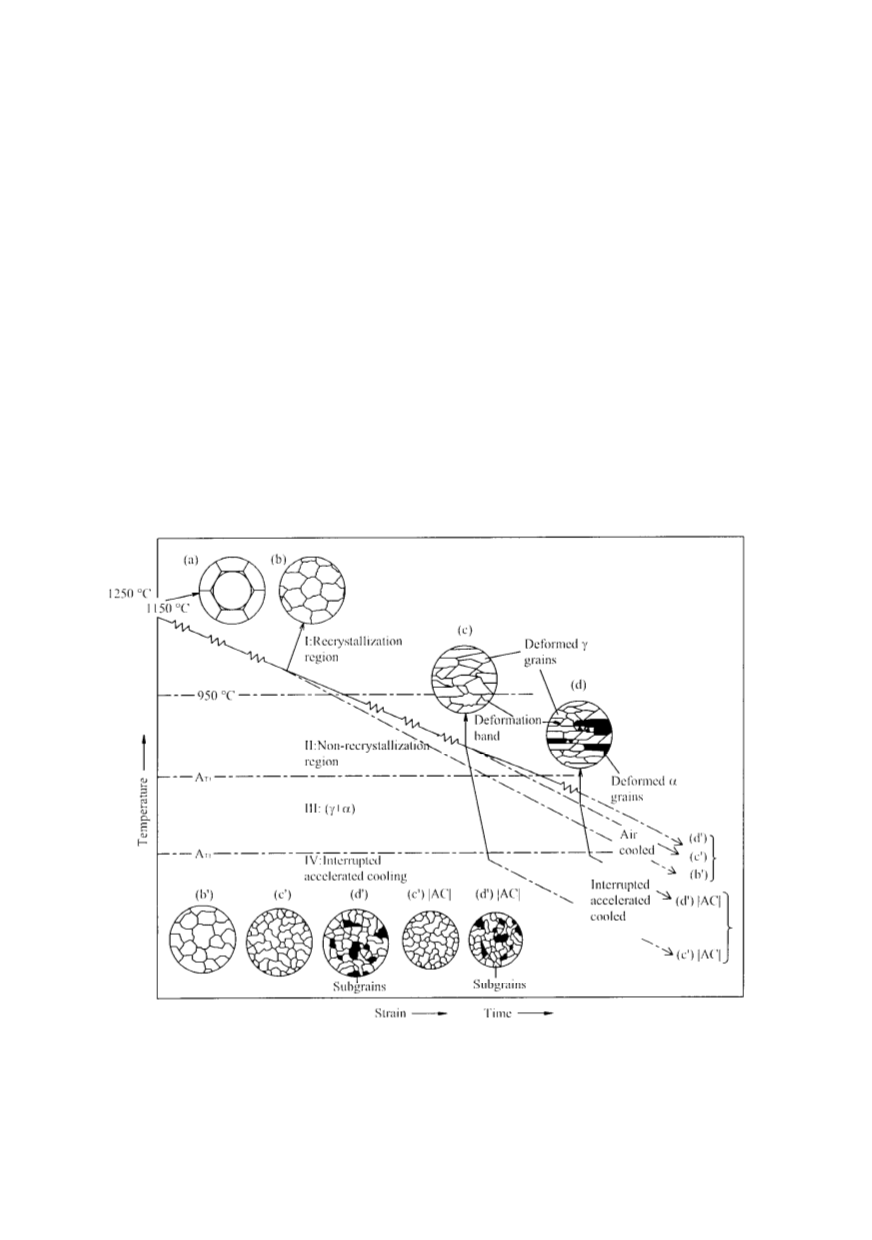

The influence on the recrystallization is the main feature characteristic for micro-

alloyed steels. The interrelationship between deformation hardening in successive passes

during hot rolling, suppression of recrystallization and cooling rate enables different ther-

momechanical processing routes for microalloyed steels, Fig. 11 /11, 14, 23, 24/.

Usual chemical composition of microalloyed steels comprises Ti (for improved welda-

bility), Nb and V (for improvement of strength and toughness via grain refinement). Very

effective particles for precipitation hardening are about 1 to 2 nm in diameter. The inter-

face of such fine precipitates is coherent with the steel matrix. These particles are typi-

cally formed during or after the

γ

/

α

transformation in the ferrite phase. With the higher

temperature of formation and a slower cooling rate the carbo-nitrides tend to grow and

become incoherent with the steel matrix. The metallurgical mechanism of precipitation

hardening changes from plastic deformation by cutting the particle to dislocation looping

avoiding the particles. Such overaged particles are less effective in increasing the strength

owing to both, their incoherent nature and the bigger particle size.

In addition to undissolved particles such as TiN, which may be as large as one

micrometer, the precipitates formed during hot working or heat treatment in austenite are

rather coarse, at around 20 nm in diameter. Thus they have only a limited effect for

precipitation hardening and their major role is in refining the microstructure.

Figure 11: Schematic illustration of thermomechanical rolling of microalloyed steels /23/

Influence on austenite decomposition

During continuous cooling of medium carbon microalloyed steels, the main goal is to

suppress the nucleation of bainitic microstructures and to enhance formation of acicular