299

3. TYPE IV DAMAGE OF WELDED JOINTS

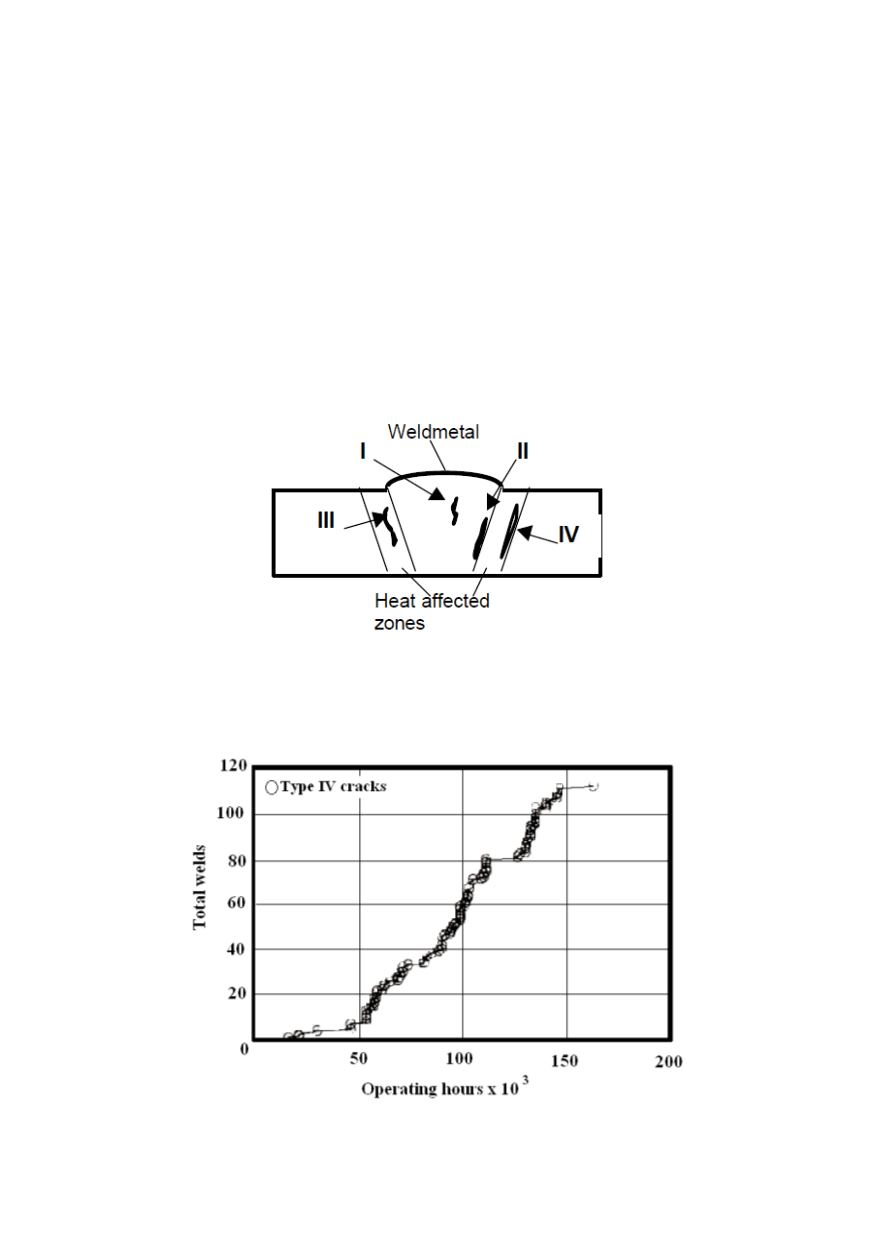

The cracking of welded joints is typically classified according to crack position and

orientation. The designations for the characterization of crack locations are illustrated in

Fig. 1. The classification of cracks depending on location of a crack is given as Type I if

the crack location is in the weld metal, Type II if the crack starts at the fusion line, Type

III if the crack locates in the coarse grained heat-affected-zone (CG HAZ) and Type IV if

the crack is in the fine grained HAZ (FG HAZ) or the intercritical zone (IC HAZ). Type

IV cracks manifest only in welded joints of creep-resistant steels, /8-14/.

The manifestation of type IV cracking is characterized by higher rate of creep void

formation in fined grained and intercritically annealed HAZ of the welds, what leads to

failure earlier than in parent steel. These zones contain coarse carbide particles leading to

reduction of creep strength; these particles also contribute to nucleate void formation. In a

cross-weld test, the weakened Type IV region is sandwiched between stronger parent

material and coarse-grained HAZ.

Figure 1: Classification of crack locations in welded joints

Figure 2 shows that although the Type IV failures started appearing after ~ 20000

hours, most of the failures in these steels appeared after 50000 hours of service i.e. the

Type IV failures were a medium to long term service phenomenon.

Figure 2: Type IV weld failures in conventional ferritic steels /15

/