300

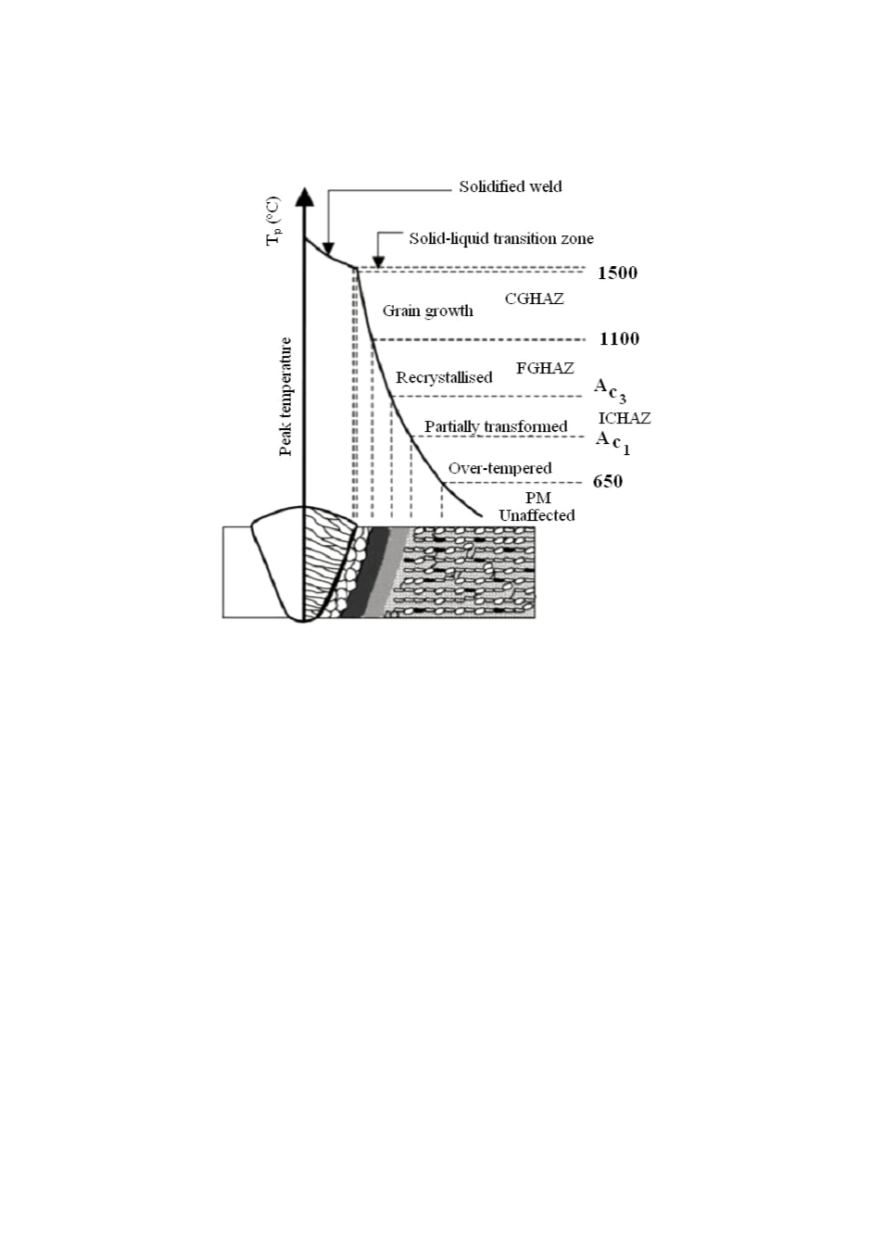

Figure 3 presents the different microstructures in the constituents of welded joint of 9-

12% Cr steels (parent metal – PM, heat-affected-zone – HAZ, weld metal - WM) /16/.

Figure 3: Typical microstructures HAZ of P91 steel formed during welding

Type IV damage, i.e. creep damage at the fine-grained HAZ (FG HAZ), usually

appears at the interior of the thickness where the stress state is more complex than at the

surface. Therefore, it is difficult to evaluate the remaining life by non-destructive

techniques (NDT) which are applied for the outer surface, such as replication method.

After several incidences of failure in thermal power plants, Type IV damage has been

the issue of many studies. The conclusion was that the damage was caused by lower creep

strength of FG HAZ compared to that of CG HAZ in weld metal and parent metal.

4. HEAT AFFECTED ZONE SIMULATION PROCEDURES

In order to characterize different regions within the heat-affected-zone (HAZ) of a

welded joint, HAZ simulation procedures are applied to parent material. It is generally

intended to apply a temperature-time history as experienced in a distinct sub regions of

the HAZ, which can be either measured by inserted thermocouples or predicted

numerically (described in the German code SEW-088).

The mechanical properties and creep behaviour of the individual HAZ sub zones can

be characterized on simulated specimens. It is important to check whether the creep

fracture occurred in the homogeneous microstructural length of the specimen. One of the

main points of creep testing simulated HAZ specimens is to find out the weakest sub

region so called “soft zone”. Therefore is recommended to apply a series of different peak

temperatures and to draw a plot of hardness or any creep test result as a function of the

peak temperature and to compare it with the data of the parent material.