290

Calcium injection in the ladle and tundish has been successfully attempted to:

(1) transform large alumina inclusion clusters into liquid calcium aluminates inclu-

sions, which after solidification and during subsequent hot and cold rolling are elongated

and fragmented into smaller sizes that do not impair steel properties;

(2) reduce nozzle clogging and eventual blockage by alumina inclusions, sustaining a

consistent melt flow rate through the nozzle and a desired melt flow pattern in the mould

to maintain productivity and cast product quality;

(3) convert dissolved sulphur into oxysulphide inclusions that are non-deformable

during hot rolling, thus preventing the formation of deformable manganese sulphide

inclusions in plate or strip; and

(4) improve the isotropy of mechanical properties and resistance to Hydrogen Induced

Cracking (HIC) that are caused by the elongated manganese sulphide during hot rolling.

In MnS inclusion present Ca changes both the surface tension and Young’s modulus.

The increase in Young’s modulus leads to high strength of particle that will not allow it to

be deformed during rolling. Also, simply by changing shape from needle like (after

rolling) to spherical (both before and after rolling), the stress concentration at the particle

was significantly decreased. This improvement was directly based on knowledge

provided by fracture mechanics, i.e. addition of Ca primarily influences the shape of

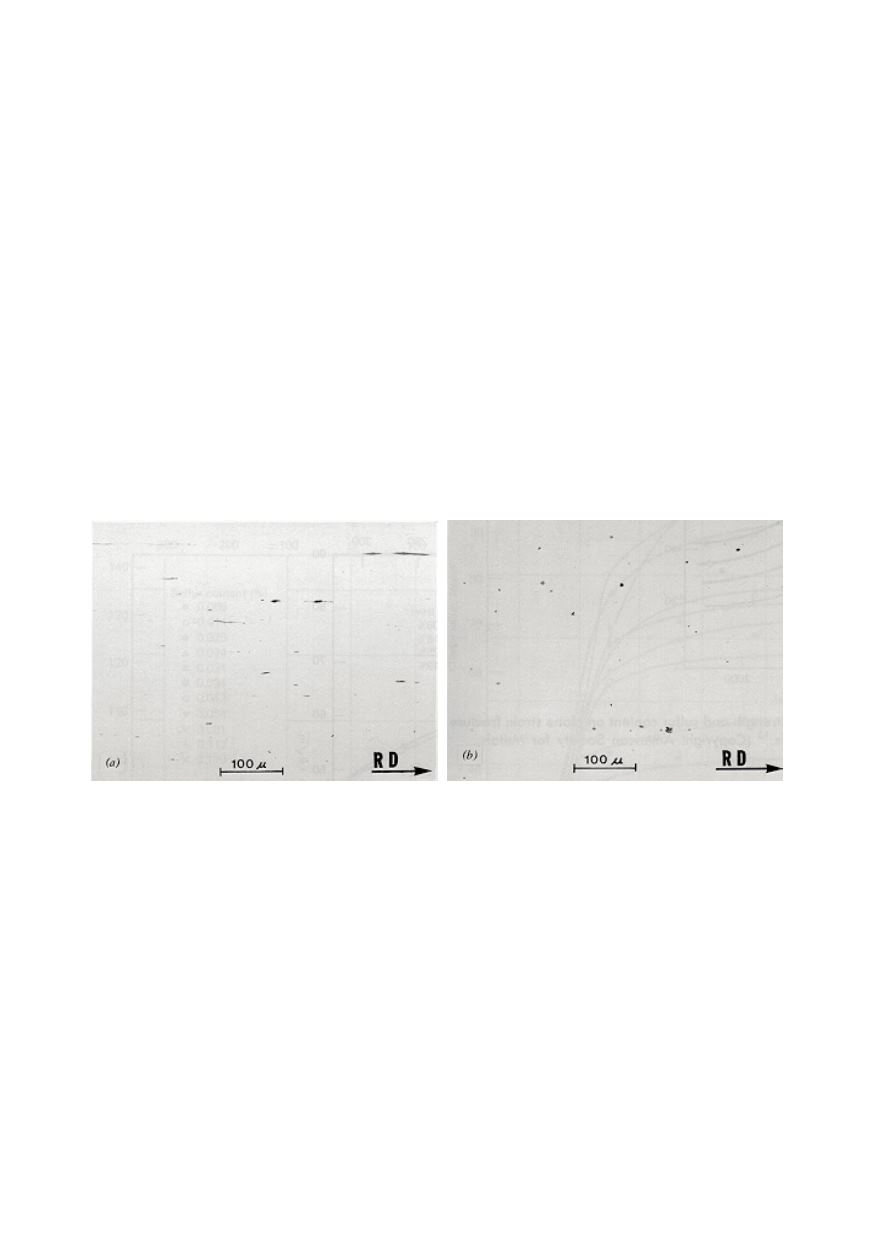

MnS. This feature is shown in figure 7 /5/.

Figure 7: Shape of MnS after rolling: no Ca added (left); addition of Ca (right) /5/

RD

→

Rolling direction

Figure 8 shows the fracture surface by scanning electron microscope (SEM) in two

steels: (a) Ca untreated and (b) Ca treated /9/. In the Ca untreated, the facets typical for

brittle fracture are present together with elongated MnS inclusions. On the other hand,

fractograph of Ca treated steel clearly show presence of spherical MnS particles with

evidences of ductile fracture.

Finally, the usual amount of Ca addition in steel is approx. 40 ppm. It is easy to do it,

not expensive and no degradation of any mechanical or technological property will occur.

Also, this treatment has significantly improved weldability, because it had largely

removed problems related to lamellar tearing.

4. BENEFICIAL ROLE OF PARTICLES

Experiences gained on the problems of inclusions control, parallel with understanding

new phenomena in physical metallurgy, have triggered new ideas in order to use some