292

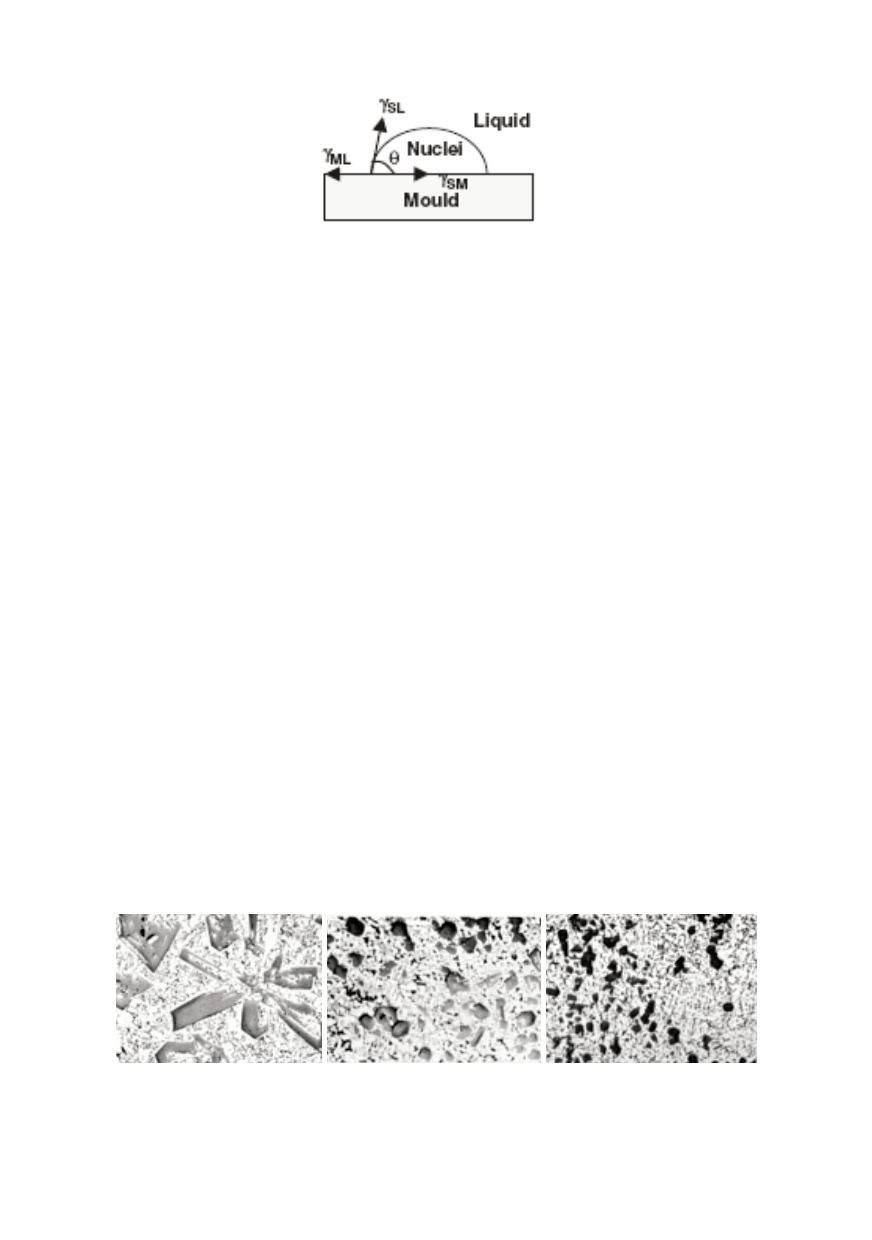

Figure 9: Heterogeneous nucleation during solidification on a mould wall. The designation on the

figure is related to Eq. (3) /18/

The equal energetic balance is considered if instead of solidification, a precipitation

occurs on present particle and grain boundary.

It is well known that at liquidus temperature, first fraction of metallic materials starts

solidification. The nuclei are, in accordance to Eq. (3), formed on the wall of the mould,

leading to formation of dendrites. Dendrites are characterized by its characteristic shape.

They lead to chemical and structural inhomogenities. This type of microstructure has very

low plasticity, relatively high hardness and strength, but very poor toughness. In order to

increase the toughness of as cast microstructures, the main challenge was to decrease the

size of dendrites. The main route was to introduce extremely large number of places on

which the nuclei of the dendrites can occur. The best possibility was to make some modi-

fications of the chemical composition of liquid metal, in order to obtain large number of

particles. These particles are high temperature oxides or sulphides and they are formed

within the liquid phase. From the start of cooling, each of them acts as example shown in

Fig. 10, i.e. as a place for heterogeneous nucleation. In some cases, the classic dendritic

solidification is not occurring, but formation of equiaxial grains. Therefore, within the

equal volume, larger number of places for start of nucleation will lead to smaller

dendrites. Smaller dendrites will improve mechanical properties, i.e. yield stress will be

increased, together with toughness. Figure 10 shows the effect of modification of

solidification microstructure due to phosphorus refinement on the microstructure of Al-

22Si-1Ni-1Cu alloy. Figure 10.a show extremely large primary crystals, within the

eutectic mixture. These large crystals actually serve as stress concentrators, resulting in

very low toughness. Addition of phosphorus will modify the places for primary crystals

solidification, Fig.10.b, i.e. their number is dramatically increased. Therefore, no large

primary crystals can be observed and microstructure with higher toughness is obtained.

Figure 10.c show the microstructure obtained after addition of phosphorus (molten in

liquid phase) and use of flux. The particles of flux have the same role in refining the

microstructure. Also, the best effect is achieved using combined treatment with both

phosphorous and flux /9/.

(a) (b) (c)

Figure 10: Effect of phosphorus refinement on the microstructure of Al-22Si-1Ni-1Cu alloy. (a)

Unrefined. (b) Phosphorus-refined. (c) Refined and fluxed. All 100X /9/