286

where

K

Ic

is minimal, critical stress intensity factor - the material property,

σ

is design

stress, corresponding to service conditions,

a

is allowable flaw size or by non-destructive

testing (NDT) detected flaw size in a component.

Defects in material structure can be classified in two groups:

(i) cracks (induced mainly by improper machining, heat treatment, welding, design);

(ii) particles (introduced as the consequence of high level of impurities or second

phase particles).

Each of these defects causes the inhomogenities in the stress field, leading to local

stress concentration at the tip of the crack or sharp edge of the particle and resulting in

stresses much higher than nominal. Also, in order to quantify the influence of the crack

shape and its position, a geometrical factor is introduced. Finally, these defects will lead

to considerable decrease of the toughness.

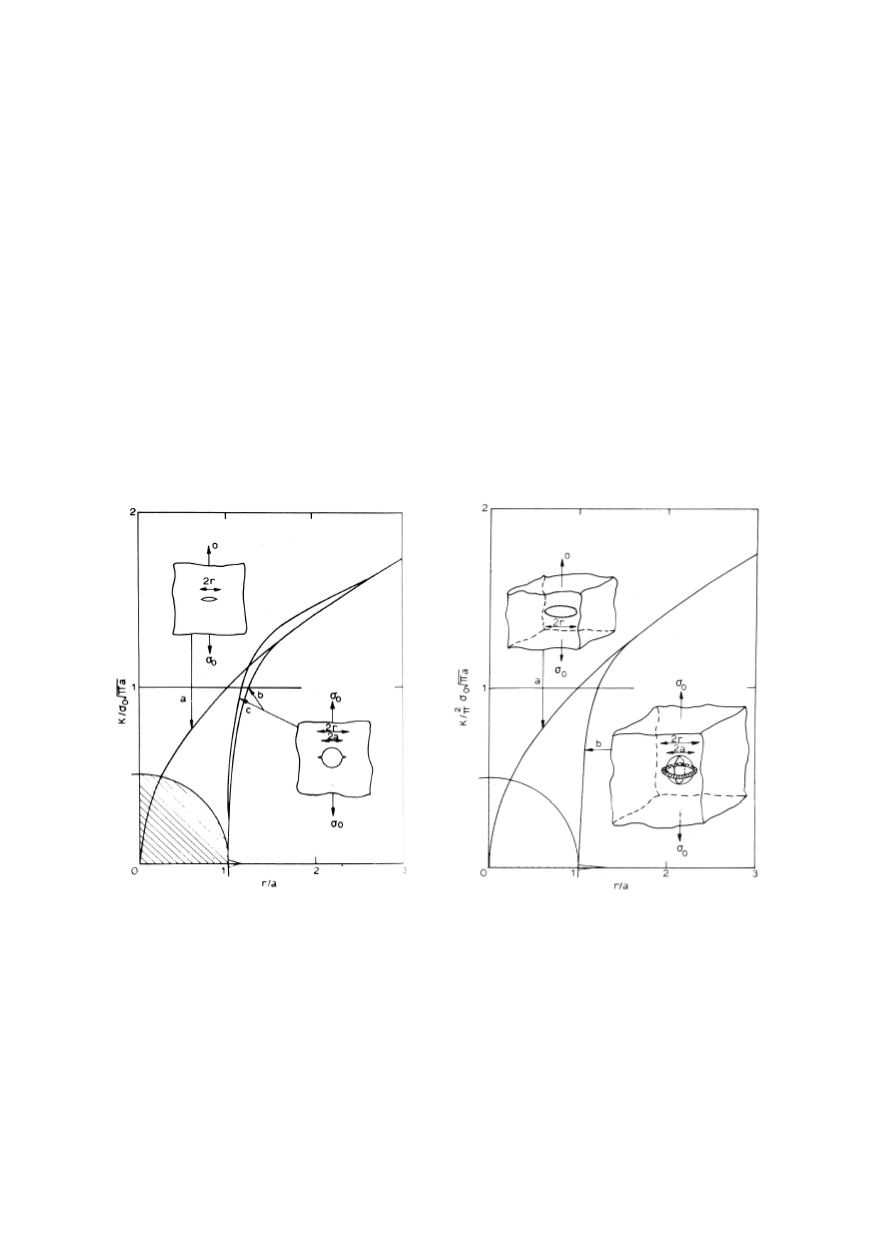

The effectiveness of the stress concentrator depends strongly on the shape. Figures 1

and 2 show the differences in normalized stress intensity for (1a) through thickness and

(1b) cylindrical cavity with symmetrical cracks and (2a) disk shaped crack and (2b)

spherical cavity with equatorial crack /4/. It is clear that when the stress concentrator is

related to minimum surface (1b and 2b), the particle size is detrimental for crack

initiation.

Figure 1: Normalized stress intensity factor for

through thickness crack (a) and cylindrical

cavity with symmetrical cracks (b) /4/

Figure 2: Normalized stress intensity factor for

disc shaped (a) and spherical cavity with

equatorial crack (b) /4/

2. NONMETALLIC INCLUSIONS

Non-metallic inclusions dominantly include sulphides, oxides, silicates, aluminates

and their compounds or composites. They can be formed both in liquid and solid state.

When formed in liquid state, the main challenge is to enable sufficient time for slag

formation and physical removal. If they are not removed from the steel melt before

solidification, they can cause defects in the casting products, give rise to processing

difficulties and failures, decrease productivity, degrade product properties, and reduce