283

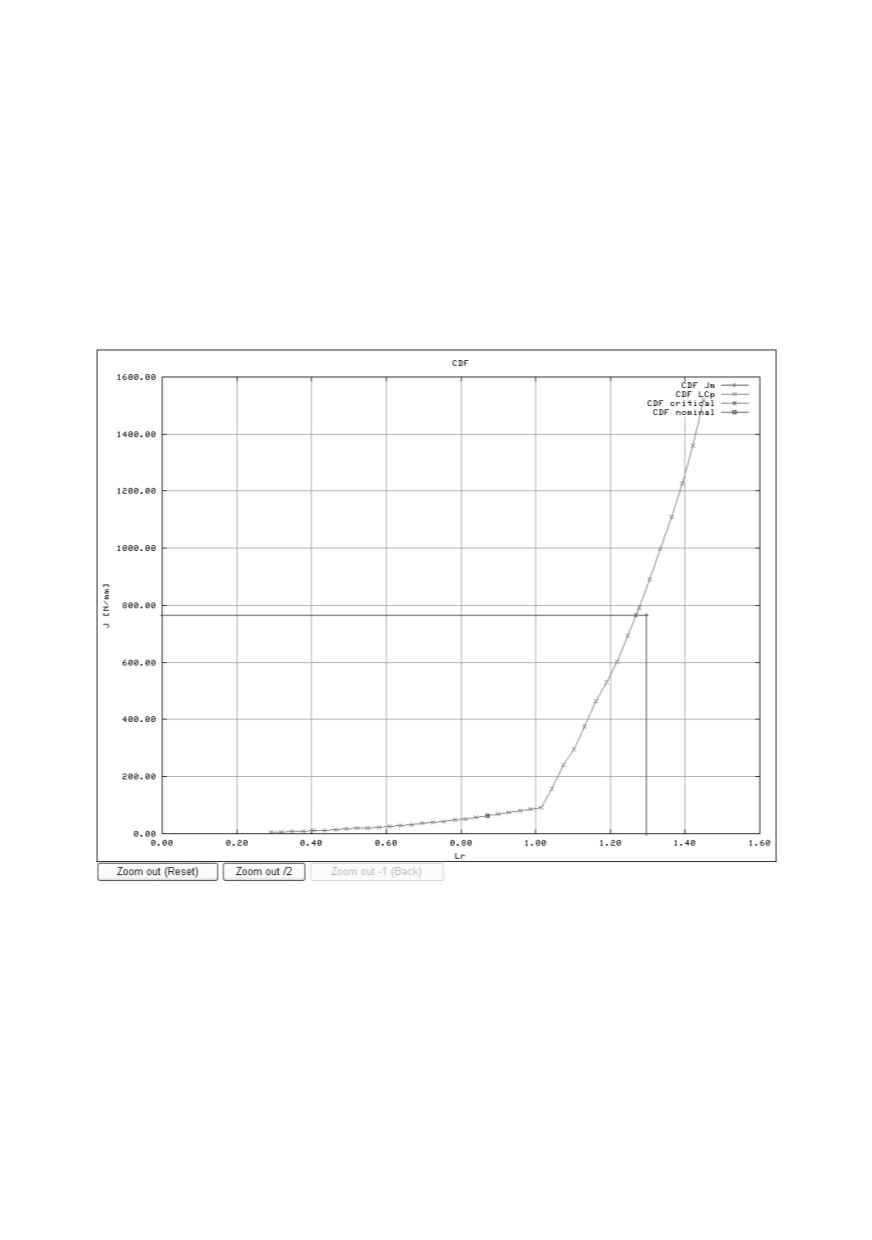

The CDF diagram (Fig. 27) also contains two main curves. The third curve is an

additional vertical straight line originating from the x-axis at the plastic collapse limit.

The first horizontal curve or line describes the fracture resistance J

mat

as the property of

the material in terms of J-integral. The area under the curve is considered as safe, the area

above it is considered as a "potentially unsafe". The second curve is the "Loading curve"

or the "Crack growth curve". It combines the properties of the material and developing

load or growing crack and describes the "Crack driving force". The nominal or operating

point with the initial crack length at designed load lies at this curve. The intersection of

both curves indicates the critical or failure point. With developing load or growing crack

the operating point slips from the "safe" towards the "potentially unsafe" region.

Figure 27: CDF diagram created from user input data

4 Conclusion

The application of the software of the Fracture module of the Procedure to real case

gives simple single but important information about materials properties requirements.

The software is possible to use in design stage (choice of right material) and using state.

Software is established with module structure which incorporates each component as

modul with known limit load solutions and stress intensity factor solution. In the software

is SINTAP concept /2/ applied for structure integrity analysis. Software check valid

conditions for solutions and provide possiblity to change stress intensity factor with new

solution or add new component. Material modul includes rutine for input mechanical