268

material parameters, the information about the shape of stress-deformation curve has to

be given (whether material exhibits continuous yielding or Lüders plateau).

The »Advanced level-A« demands a Stress-Strain curve that has to be added as two

columns of points as an R-e curve respectively (Fig. 8). Columns are separated by 'tab' or

»;«. The decimal delimiter is dot ».« or comma »,«. The Stress-Strain curve can be

described as an Engineering curve, an Engineering curve where a Ramberg-Osgood

approximation shall be performed or, as a true stress-strain curve. The Ramberg-Osgood

approximation can be used if one doesn't have enough points of the engineering R-e

curve. The minimal number of curve points is ten. However, the approximation is highly

recommended for such a small number of points in order to avoid the unusual shape of

the failure acceptance curve in FAD. That would make it useless for failure assessment.

2.4.2. Material # 2: Weld

If »Strength mismatch« was chosen, the »Material #2: Weld« is enabled and requires

the data to be filled in the same manner as in case of »Material #1: Base«. Consider that

only fields of Advanced level are enabled.

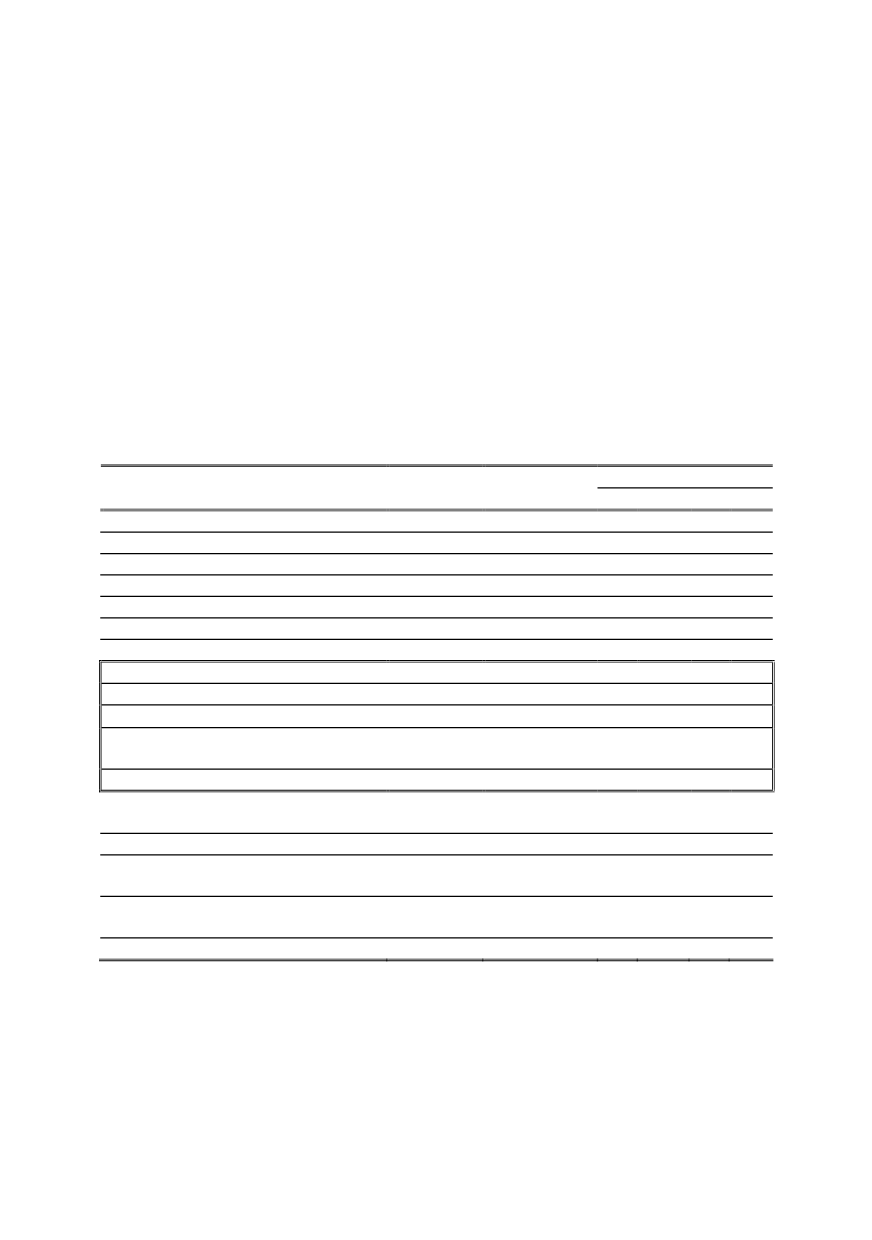

Table 1: Material properties for different procedure levels

Level

Description

Default

value

Unit

0

1

2

3

Young's Modulus of Elasticity (E)

210

GPa

9

9

9

9

Poisson's ratio (ν)

0,3

-

9

9

9

9

Plastic constraint factor (m)

1,5

-

9

9

9

9

R

el

-

MPa

9

9

9

9

R

p0.2

-

MPa

9

9

9

9

R

m

-

MPa

9

9

9

K

mat

, J

mat

, Δ

mat

-

-

9

9

9

Charpy impact energy (Cν)

J

9

or

-

-

-

-

-

Working temperature (T)

°

C

9

Temperature at 28J of Charpy impact

energy (T

28J

)

°

C

9

Probability of failure (P

f

)

%

9

Yield strength at 0.2% plastic strain

(R

p0.2

)

MPa

9

9

9

9

Tensile strength (R

m

)

MPa

9

9

9

Crack fracture resistance in terms of K,

J or δ (K

mat

, J

mat

, δ

mat

)

N/mm

1.5

,

N/mm, mm

9

9

9

Engineering stress-deformation curve

from single axis tensile test (R-e)

File

9

Stress-strain curve type

-

-

9

2.4.3. Sensitivity analysis

The variability influence of the maximum number of reached loading cycles on the

variability of input random quantities is studied by means of the sensitivity analysis.

There takes place an increase of crack initiation a

0

to critical size a

cr

.

The R-curve can be described in three ways. As a CTOD-Δa curve, as a J-Δa or in a

form of three parameters: A, C and D. In that case the parameters are entered in the field

»Crack growth fracture resistance data« in the forms using »=«, 'tab' or »;« as delimiter.