273

1

1

1

1

1

1

1

1

1

1

j

j

r i, j

j

r i, j

j

cr

c

r i, j

r i, j

r i, j

r i, j

Crack Crack

L

Crack L

Crack

k

n

L

L

L

L

−

+

−

+

+

−

−

+

−

+

−

⋅

−

⋅

=

=

−

−

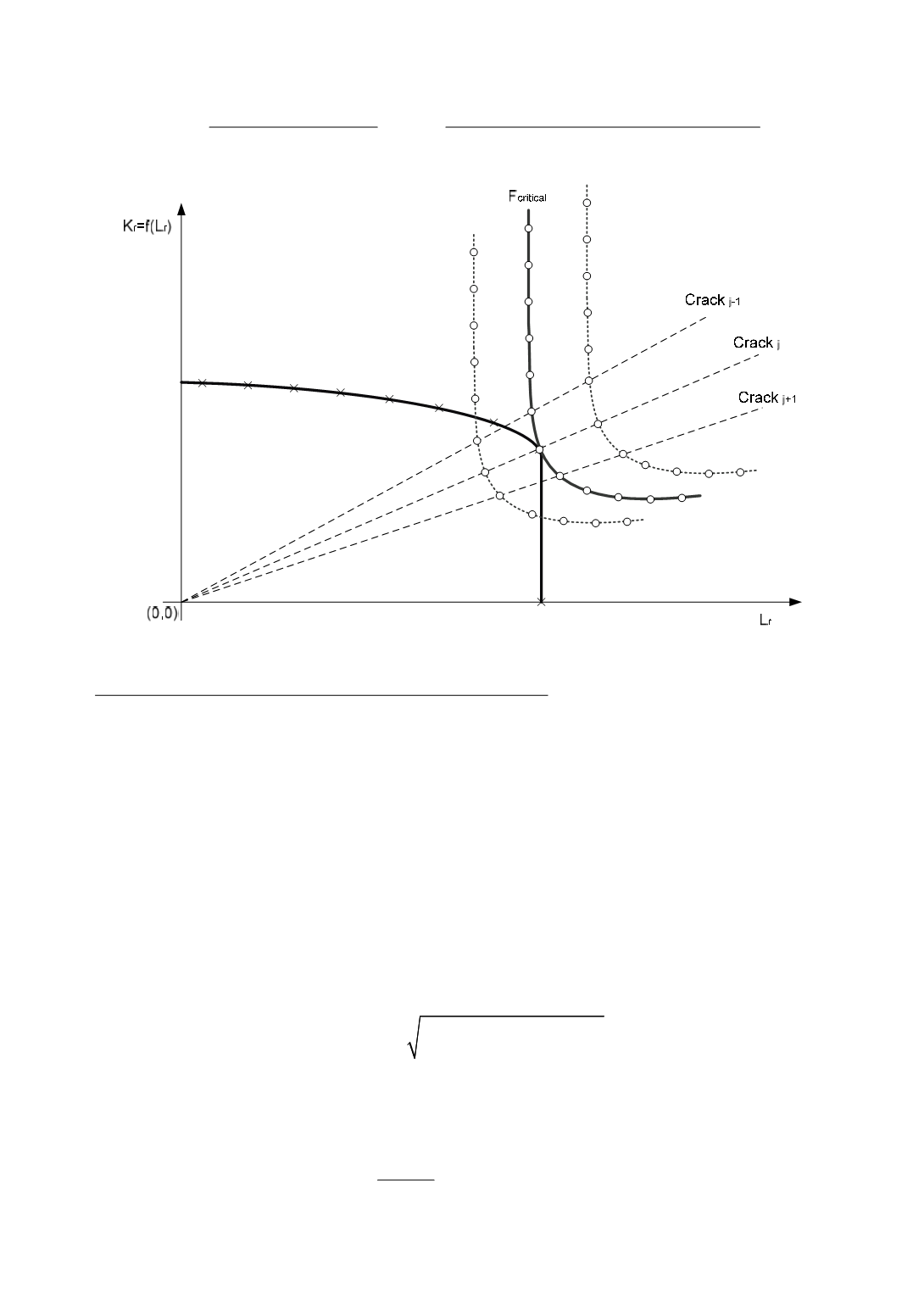

Figure 14: FAD diagrams (critical curve lies below the diagram break)

2. The critical curve lies above the FAD diagram break

First a cross-section between the FAD -

f (L

r

)

and a straight line through the knee of a

load curve is calculated (Fig. 15). Two additional curves are calculated in addition.

Taking a linear dependency between load and a same crack size, the critical load is

calculated as the knee point was the critical point. Then a short check up is performed if

all the points are really under the FAD -

f (L

r

)

curve. If the crack extension goes lower

than the knee, this is usually not the case. This depends on the user, how he or she sets the

crack parameters. Then, the maximum distance between the straight line between two

neighbouring points of FAD -

f (L

r

)

right to the knee of the load curve and the line

through the points of the load curve and (0,0) is calculated:

The load curve is moved in the direction of decreasing the dist to zero, the critical load

can be calculated by taking into account the linear dependency between the load and the

distance of the curve from (0,0). The critical crack value is defined by the point (crack)

that defines the maximum distance

dist

.

(

) (

)

2

2

i

j

i

j

i, j

dist max x x

y y

⎛

⎞

=

− + −

⎜

⎟

⎝

⎠

(8)

There exists a local minimum of the load curve. At that point the load curve will touch

the R-Curve when a proper loading is applied, as shown in Fig. 16. The local minimum is

calculated by differentiation of the load curve.

( 0)

d( J ) min

d( a )

=

=

Δ

(9)