267

and is commonly produced with yield strength,

σ

YW

, greater than that of the base plate,

σ

YB

, the case is designated with the mismatch factor

YW

YB

M

σ

σ

=

(1)

Undermatching (M<1) gives rise to a strain concentration in the weld metal and it is

therefore good practice to avoid undermatching since the local ductility in the weld metal

can be exhausted at low global deformations. Overmatching (M>1) reduces the strain in

the weld material as compared to the base plate, thus shielding a defect in the weld metal.

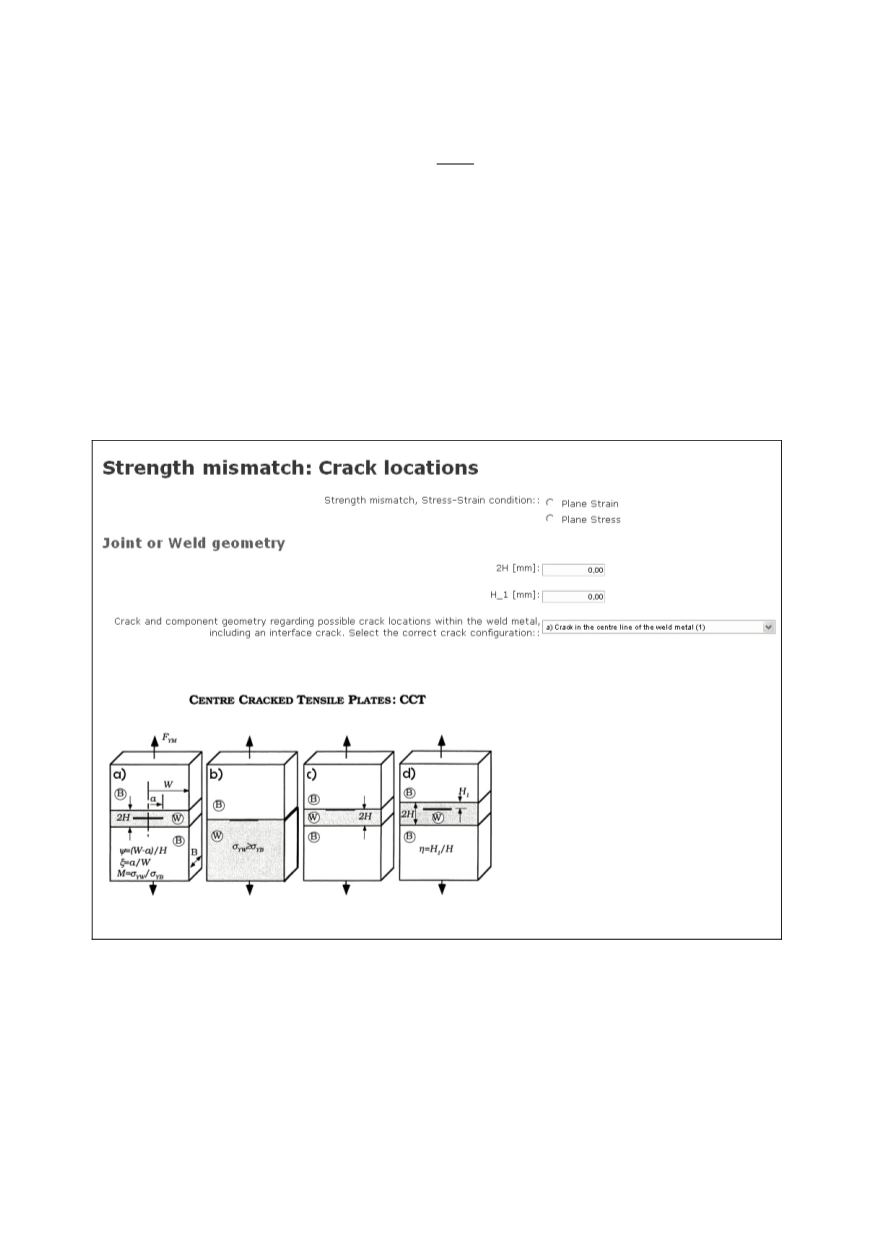

This option is only available if Strength mismatch is more than 10% (M<0.9 or

M>1.1). It is appearance depends on the selected configuration and normally requires the

following data (Fig. 7):

-

The stress-strain condition

-

Dimensions of the joint

-

Position of the crack according to the welding material

Figure 7: Crack location form (welded joints)

2.4. Material properties

The next step is to fill up the forms about the material properties.

2.4.1. Material # 1: Base

Several parameters are required accordingly to the selected procedure level, Table 1.

The dialog contains different fields to enable entering the material properties. There

are several options which depend on the level of SINTAP procedure. In addition to other