188

One mechanism proposed for striation formation during fatigue crack growth is

illustrated in Fig. 18. The crack tip blunts as the load increases, and an increment of crack

growth occurs as a result of the formation of a stretch zone. Local slip is concentrated at

45° from the crack plane. When the load decreases, the direction of slip is reverse, and

the crack tip folds inward. The process is repeated in subsequent cycles, and each cycle

produced a striation on the upper and lower crack faces. Width of striation depends on

fatigue crack growth rate in 7000 aluminium alloys with different content of (Fe+Si), Fig.

19. For the same

ΔK

, a greater striation spacing confirm the faster crack grow in the alloy

with maximum impurities content, Fig. 19.a

,

than in its high-purity versions, Fig. 19.b /9/.

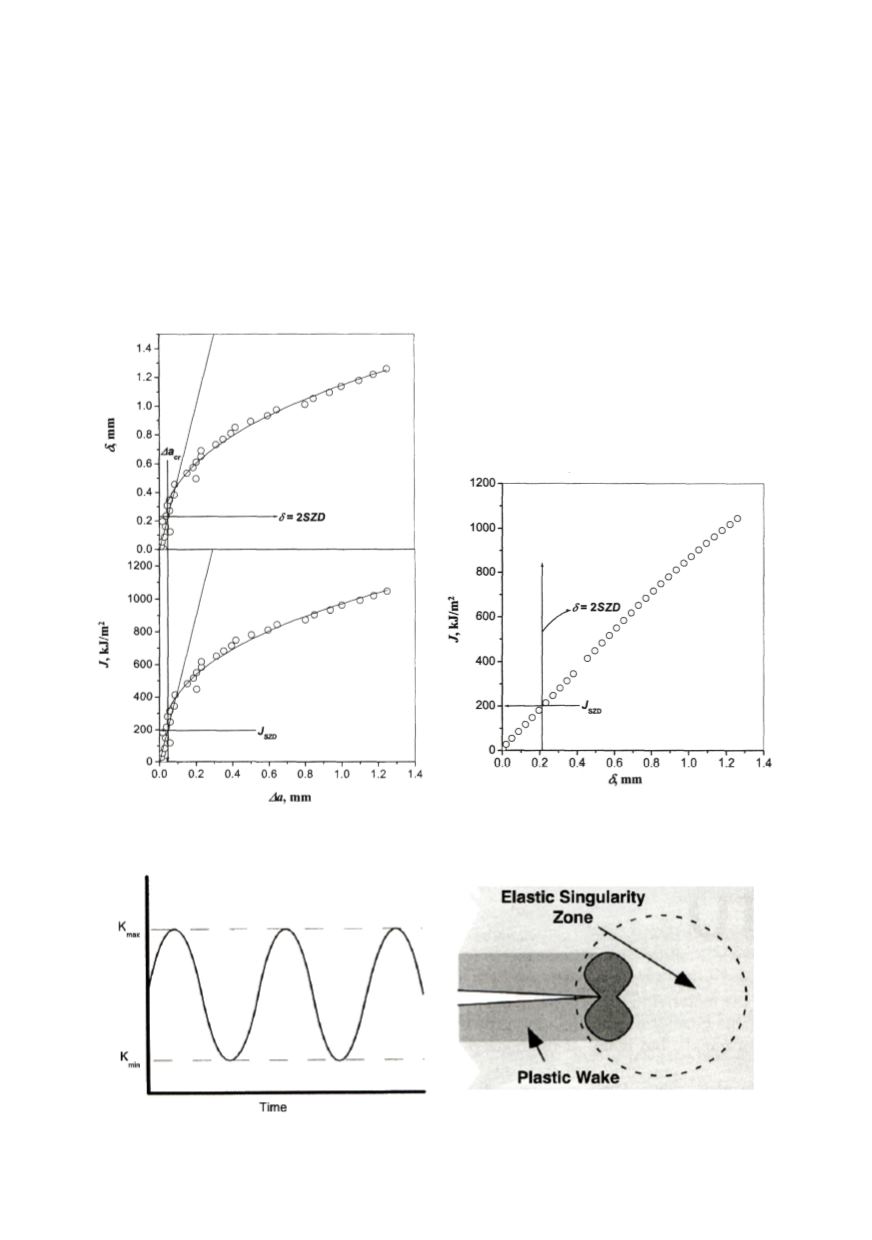

a. First method

b. Second method

Figure 16. Determination of

J

SZD

from SZD /9/

Figure 17: Constant amplitude fatigue growth under small-scale yielding conditions