147

deformation in post-weld machining, stress corrosion cracking and fracture /2/. The

tensile and compressive stresses are balanced in neighbouring areas to be in equilibrium.

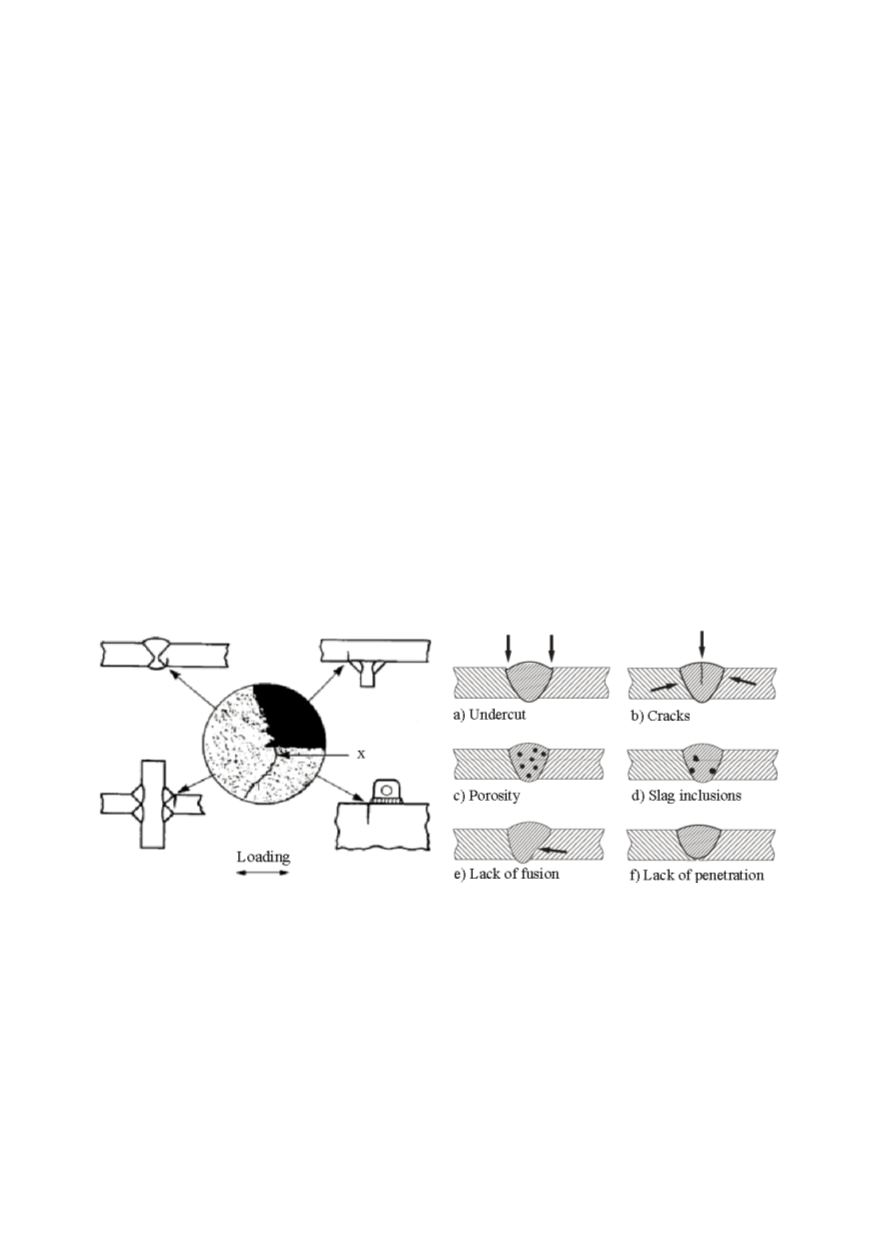

2. WELD DISCONTINUITIES AND THEIR EFFECTS

Different discontinuities and cracks in the deposited weld metal (WM) or in the heat-

affected-zone (HAZ) of the base metal (BM) can occur in produced welded joints /1, 3-4/

.

They introduce stress concentration regions, shown in Fig. 2 for different types of weld-

ments.

Codes and specifications define acceptance levels for discontinuities in terms of

their type, size, orientation, and distribution. Usually, cracks and crack-like discontinui-

ties are not acceptable. Discontinuities are designated as defects only when their size,

orientation, and distribution exceed specification limits and their presence affects the

integrity of the component, making it unsuitable for its intended application.

Various types of weld discontinuities, cracks, and imperfections, their causes and me-

thods to avoid them are considered in many references. In general, the weld discontinu-

ities might be caused by: (1) improper design that restricts accessibility for welding; (2)

incorrect selection of a welding process or welding parameters; (3) improper handling of

consumables, and (4) other causes including welding performance. These observations

are cited to emphasize that quality assurance in welding requires considerations and pro-

per decisions, starting with the design stage and continuing throughout the entire fabri-

cation process. Weld discontinuities can be classified in three basic groups:

1. Crack-like discontinuities (cracks, lack of fusion, lack of penetration, overlap)

2. Volumetric discontinuities (porosity, slag inclusions)

3. Geometric discontinuities (undercut, incorrect profile, misalignment)

Most frequent defects and crack-like discontinuities in weldments are shown in Fig. 3.

Figure 2: Stress-concentration regions weldments Figure 3: Defects and cracks in welded joint

The mere existence of discontinuities does not indicate a loos of product's fitness for a

given application. Product suitability for service is based on the severity of the disconti-

nuity, depending on their size, shape, and orientation, assessed according to applicable

specifications and analyses, and on the magnitude and direction of applied stresses. The

severity of discontinuity increases with its size, when it is closer to planar form and

loaded by perpendicular tensile stresses. Volumetric discontinuities are less injurious than

planar, crack-like discontinuities. The discontinuities oriented in stress direction might be

innocuous compared to that of same size perpendicular to the tensile stress, which can be

danger. Surface discontinuity with plane perpendicular to the tensile stresses is more