117

In the case of linear-elastic deformation behaviour, the crack tip loading can be

determined by superposition the K factor due to primary and the K factor due to

secondary stress:

I

I

p

s

r

mat

K K

K

K

ρ

+

=

+

(1)

and in the CDF route as,

2

I

I

1

p

s

'

r

K K

J

f ( L )

E

ρ

⎡

⎤ +

= × ⎢

⎥

−

⎢

⎥

⎣

⎦

(2)

2

I

I

1

p

s

Y

r

K K

E'

f ( L )

δ

σ

ρ

⎡

⎤ +

=

× ⎢

⎥

⋅

−

⎢

⎥

⎣

⎦

(3)

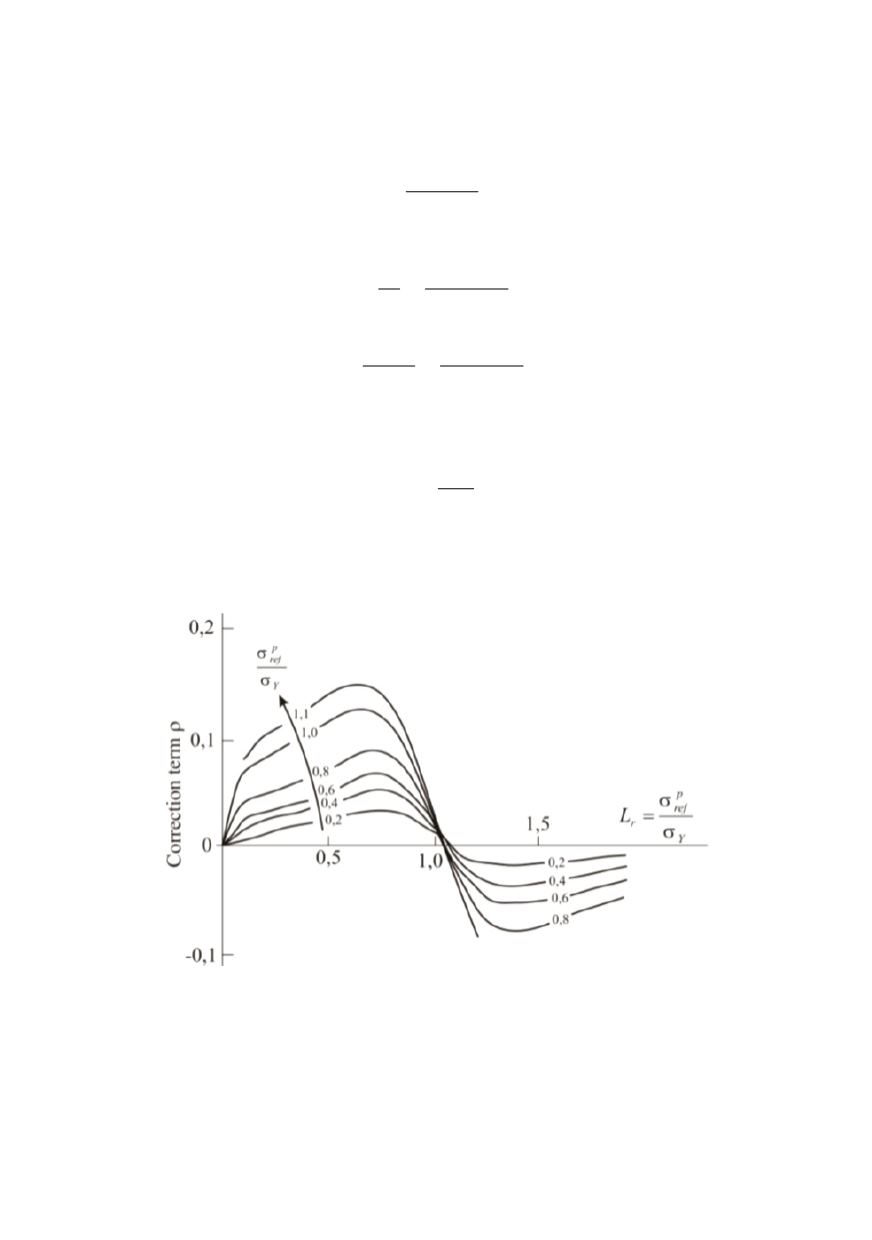

The quantity

ρ

characterizes the difference between the actual crack tip loading and

the crack tip loading which would result from simple superposition of

K

I

p

and

K

I

s

. Using

p

ref

r

Y

L

σ

σ

=

(4)

it is dependent on the ligament of plasticity,

L

r

(which is a function on primary loading,

on the magnitude of the secondary stress, and on the equation applied for

f

(

L

r

).

Therefore, the correction term

ρ

can be determined from the plot given in the Fig. 13.

Figure 13: Correction term

ρ

in function of

L

r

6.3. Crack type and orientation

Real flaw shapes are idealized by substitute geometries such as rectangles, ellipses and

semi-ellipses (Figs. 14 and 15). The idealization has to been done such that the crack tip

loading will be overestimated.