80

criterion and the CGM. First of all, it can be seen that the load-carrying capacity of the

material is overestimated if damage due to the voids is not taken into account (von Mises

criterion). These results can be improved using the node release technique, as explained,

but in this analysis it is chosen to model the crack growth by development of damage in

the ligament, using the CGM. It is shown that this procedure can give appropriate results,

and predict the weakening of the material caused by the nucleation, growth and coalesc-

ence of voids during the process of ductile fracture. Very good agreement with experi-

mental data is achieved for 6 and 12 mm wide joints, while certain differences exist in

case of the widest joint (18 mm), where the estimated values of force are larger, but with

correct trend that reflects the loss of load-carrying capacity of the material.

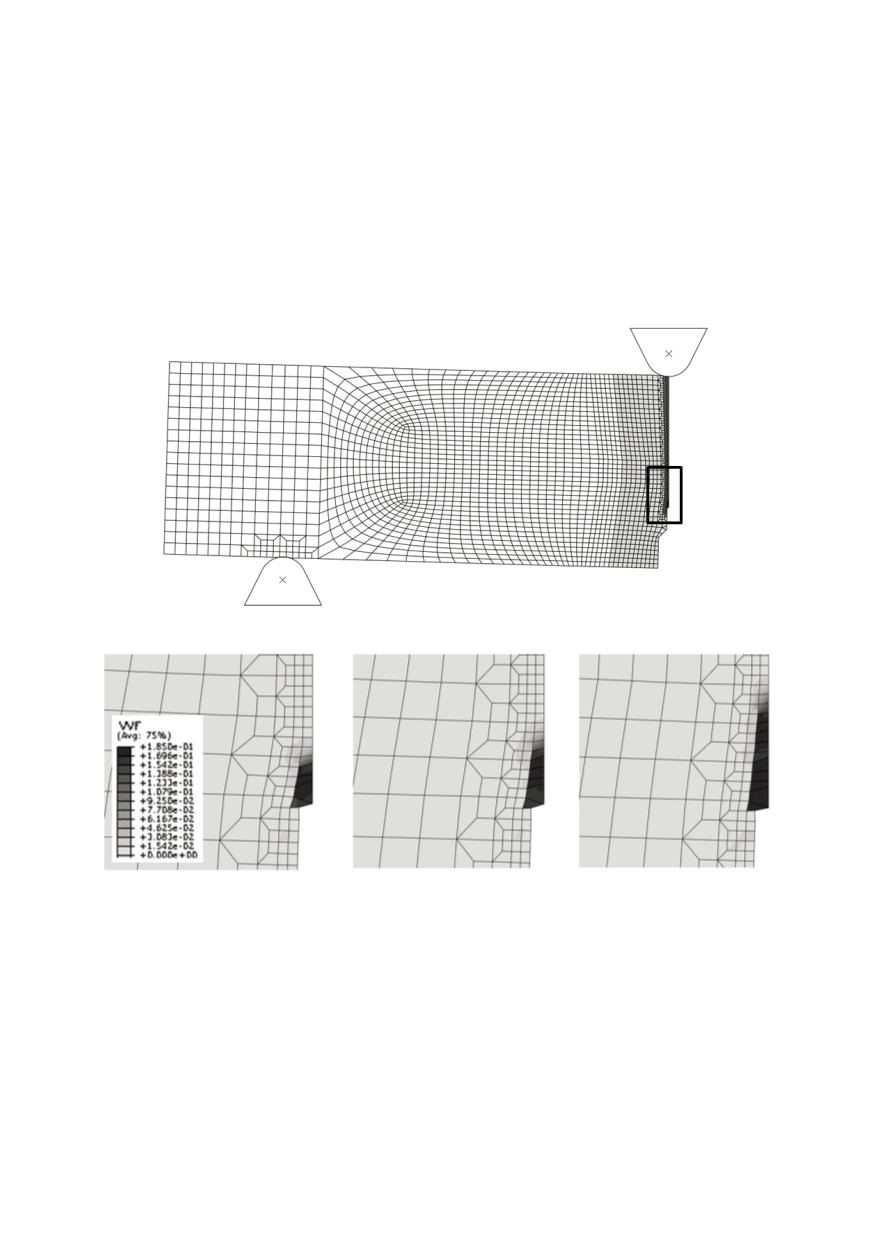

Figure 10: Deformed FE mesh of one half of SENB specimen, joint width 12 mm

(a)

(b)

(c)

Figure 11: Detail of deformed FE mesh in the ligament in front of the crack tip,

joint width 6 mm (a), 12 mm (b) and 18 mm (c)

The influence of the secondary voids formed around the Fe

3

C particles on the crack

growth initiation is also analysed using the CGM. Volume fraction of these particles in

the weld metal,

f

N

= 0.002257, is determined using the lever rule /41/. Results obtained

using the approach of Chu and Needleman /27/ are shown in Fig. 15. The adopted values

of

ε

N

and

s

N

are 0.3 and 0.1, respectively. It is concluded that secondary voids in the

analysed weld metal do not contribute to the decrease of the load-carrying capacity. Such

behaviour is not a surprise, having in mind the low contents of carbon, and therefore also

Fe

3

C particles.