304

the reprecipitation of M

23

C

6

carbides and MX carbonitrides during the subsequent

tempering treatment (PWHT) is very limited. In addition, the coherent MX particles

coarsen and coagulate and lose their strengthening effect to a large extent. These effects

also create a higher tendency towards recrystallisation in this area which, in connection

with the overaging of the precipitates, results in a significant softening of these fine

grained zones of the HAZ which were heated up to 900-950°C during the weld thermal

cycle after PWHT, /17/.

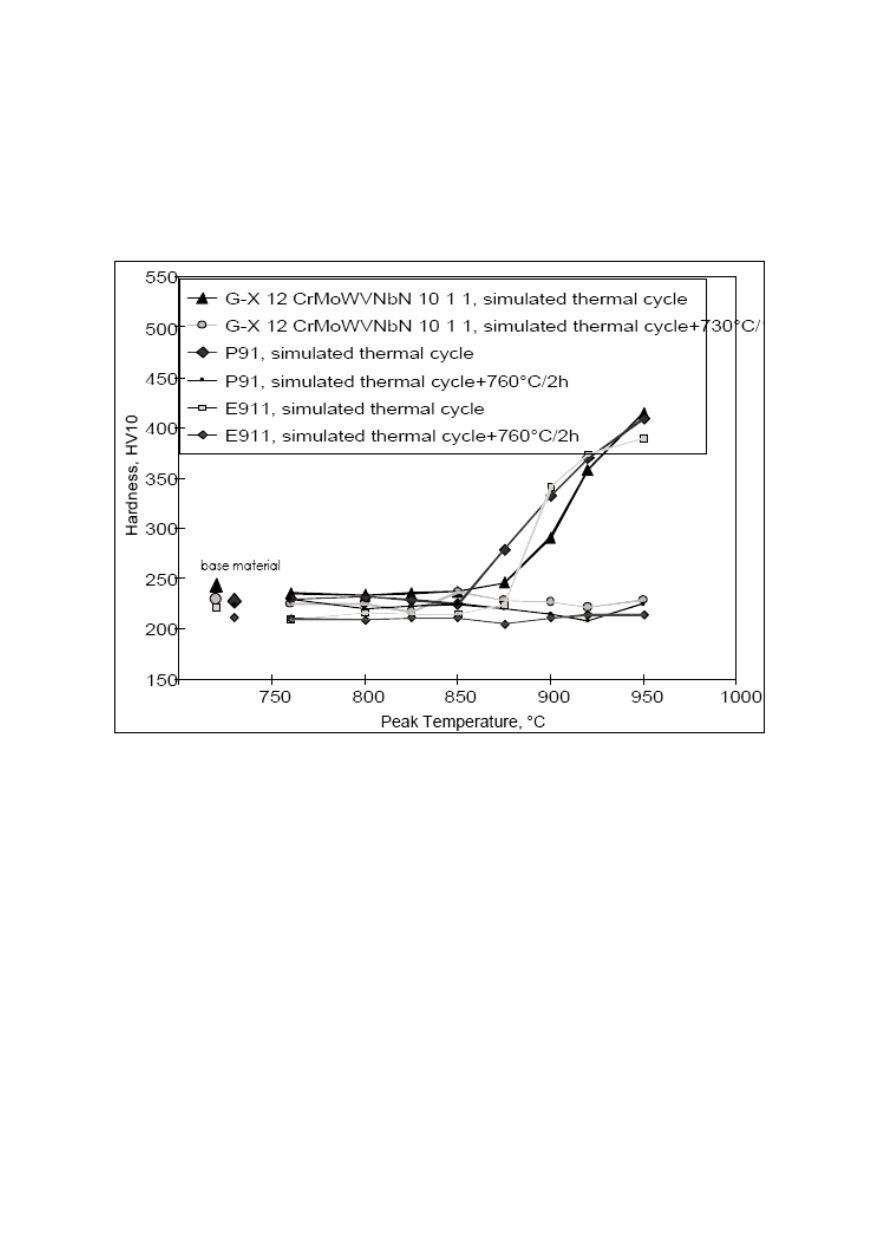

Figure 6: Results of hardness measurements on specimens of P91, E911 and G-X12CrMoWVNbN

10 1 1 subjected to weld thermal cycle simulations (determination of soft, intercritical zone) /17/

6. DETERMINING OF THE “SOFT ZONE”- CASE STUDY

For this investigation, a tube of steel P91, Ø 320 mm, with wall thickness of 14 mm

and 140 mm long was used, /23/.

Typical temperatures of transformation during the welding cycle were determined

from dilatometric curve, and these are A

c1

=835°C and A

c3

=930°C, Fig. 7. Heating rate

was 53.8 °C/s. During cooling, formation of martensite started at temperature of 375°C,

while martensite transformation completed at temperature of 210°C. Martensite formation

was preceded by separation of a smaller quantity of bainite, /21/.

6.1. Simulation

For testing of the effects of various thermal cycles of welding on microstructure and

mechanical properties of test material using thermal simulator SMITWELD, the

specimens 11x11x70 mm were used. Different HAZ regions were obtained by simulation

of single-pass welding at temperatures of 1386°C, 1300°C, and 1250°C up to 950°C,

graded by 50°C, 925°C, 900°C and 850°C and with cooling time between 800°C and