305

500°C, t

8/5

, 40 sec. After welding, the samples were subjected to PWHT at 730°C for 1

hour. Then all samples were subjected to inspection of microstructure and measurement

of hardness.

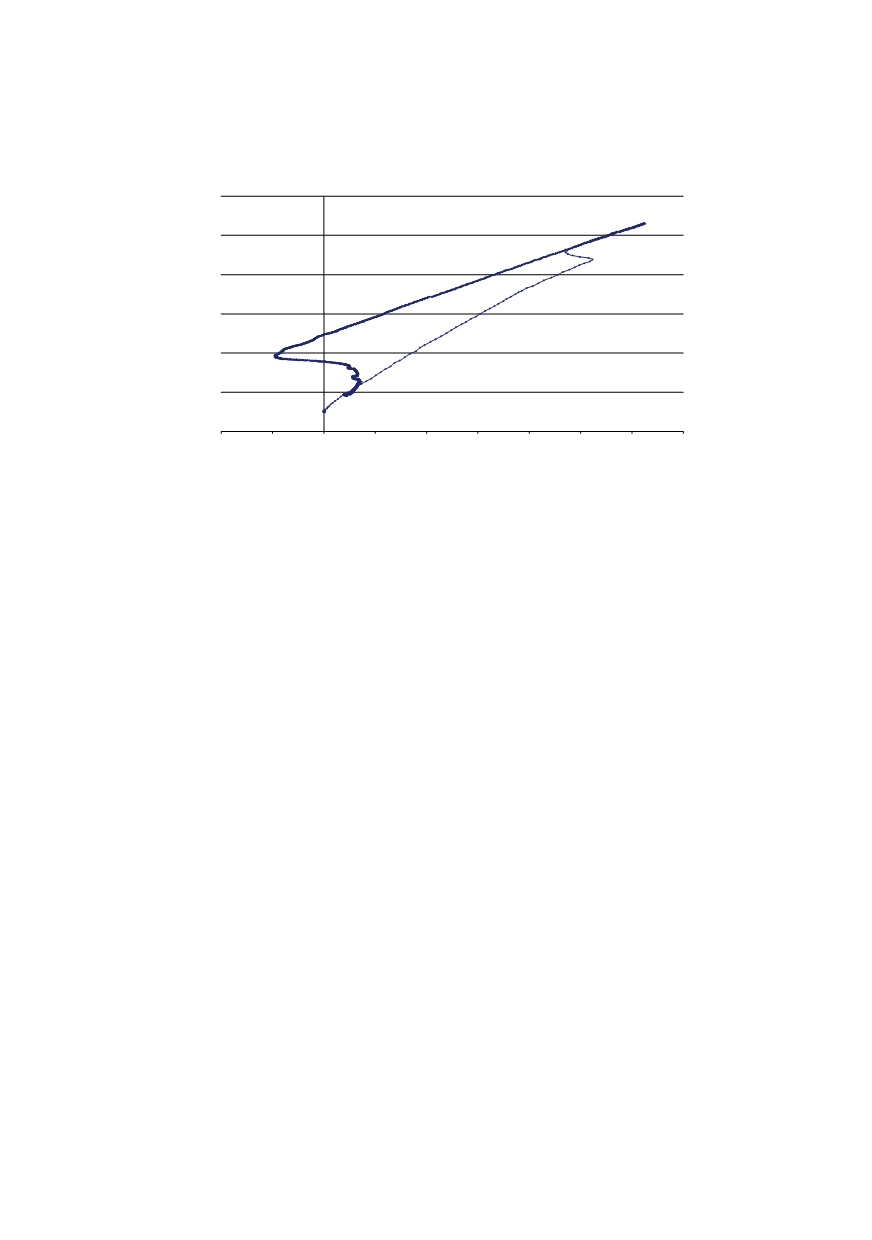

Figure 7: Dilatometric curve

6.2. Material

The appearance of microstructures at temperatures of 925°C, 1100°C, 1300°C and

1386°C is shown in Fig. 8. The microstructure corresponding to austenitisation

temperature of 925°C, Fig. 8 a, consists of martensite with less prominent martensite

laths. At some previous austenitic grain boundaries, the presence of coarser carbides

above 1 µm was observed. The presence of the carbides is most probably the result of

keeping at austenitisation temperature for a short time, considering that the carbides of

M

23

C

6

type completely dissolve at temperatures above 900°C /19/.

The microstructure corresponding to austenitisation temperature of 1100°C, Fig. 8 b,

consists of tempered martensite with clearly visible martensite laths. Coarser carbide

particles above 1µm are still present.

The microstructure corresponding to austenitisation temperature of 1300°C, Fig. 8 c

and 1386°C, Fig. 8 d, also represents tempered lath martensite. Carbide particles above

1µm at the boundaries of previously austenitic grains practically are not present.

6.3. Hardness

Hardness of parent metal of 230 HV1 was measured. Variation of hardness of

simulated samples with temperature of simulation showed a drop at 925°C, Fig. 9, and

that is why this temperature of 925°C was chosen as representative of “soft zone”.

A significant drop of hardness of almost 40HV occurs at simulation temperature of

850°C that is somewhat above A

C1

temperature. With an increase of simulation

temperature, ferrite fraction transforming into austenite increases. At temperature of

925°C, this fraction was approx. 90%. At this temperature, there was no considerable

dissolution of carbides and nitrides and transformation of C and N into solid austenite

solution. Therefore, martensite formed at cooling had significantly lower content of C and

N. Due to decreased content of C and N, repeated separation of M

23

C

6

carbides and MX

carbonitrides during subsequent heat treatment was limited resulting in hardness lower

than that of base metal.

Dilatometric curve at 1050°C

0

200

400

600

800

1000

1200

-40

-20

0

20

40

60

80

100

120

140

Dilatation [μm]

Tp [°C]