303

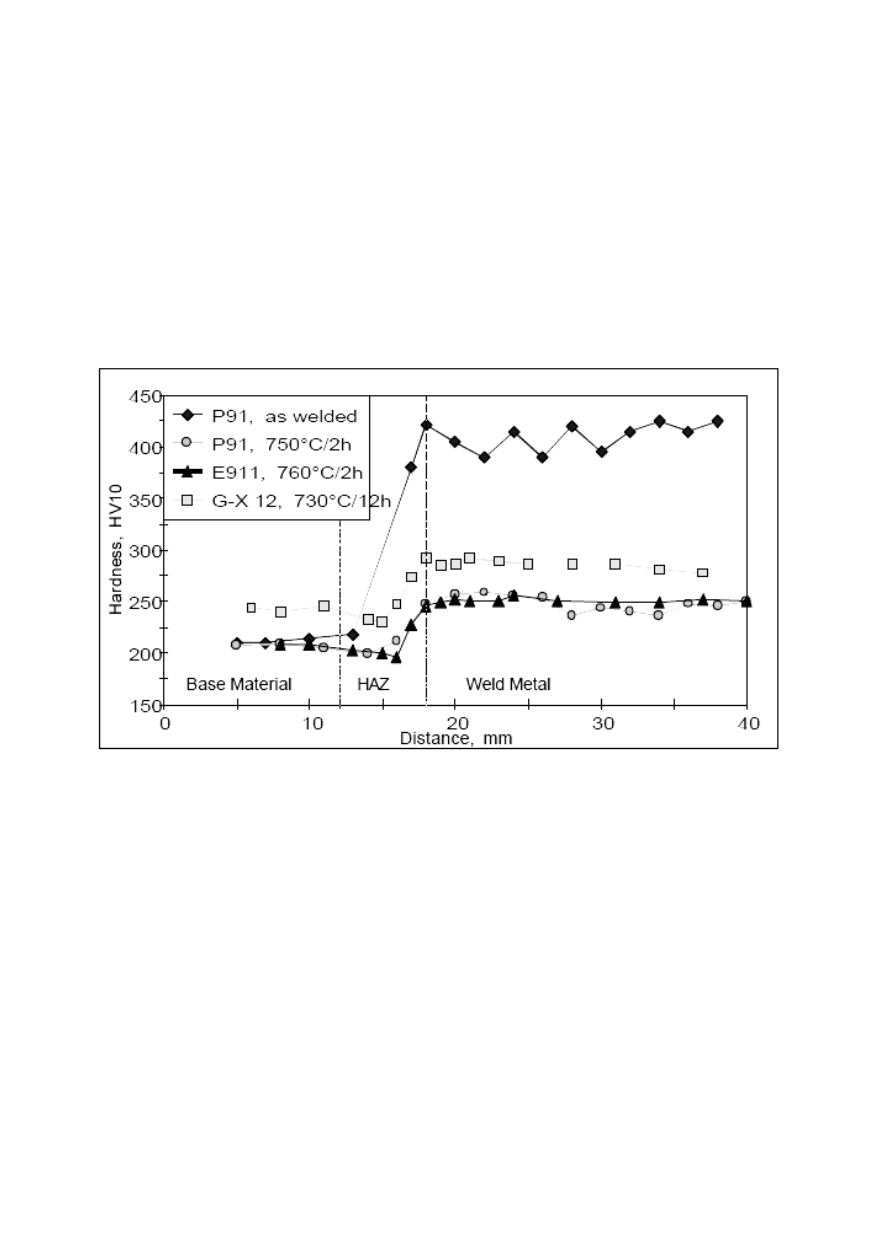

profiles of steel grades E911 and G-X12CrMoWVNbN 10 1 1 show a similar curve to

that of P91. To define the zone in which maximum softening occurs, specimens were

subjected to a HAZ simulation at different peak temperatures in the range between 760°C

and 950°C. The hardness was tested in the as-welded, simulated and in the simulated

PWHT conditions (760°C for 2 hours air cooled for P91 and E911 and 730°C for 12

hours for G-X12CrMoWVNbN 10 1 1).

The results of the hardness tests performed on the simulated microstructures of the

three mentioned materials are presented in Fig. 6

as a function of the peak temperature for

both, the as-welded and PWHT conditions. The beginning of α/γ-transformation as a

function of heat cycles can be observed by the increase of hardness in the as-welded

condition. After stress relieving, the hardening effect disappears and a small drop of about

10HV can be detected for peak temperatures between 850°C and 950°C.

Figure 5: Hardness of weld seam in as-weld condition and PWHT of P91, E911 and G-

X12CrMoWVNbN 10 1 1 /17/

5.2. Microstructural aspects

As described in /19-25/, the microstructure of the normalized and tempered P91 steel

consists of tempered martensite with a large amount of M

23

C

6

and MX precipitates.

Microscopic examination of the specimen subjected to HAZ simulation thermal cycles

revealed no significant change in the microstructures when the peak temperature did not

exceed 850°C. When the peak temperature becomes higher than the A

c1

temperature,

depending on the shape of the thermal cycle, more and more austenite will be formed and

transformed into martensite during cooling to room or preheating temperature. When

heating up to 920°C, the amount of martensite which was found under given conditions

of our tests is about 70-90%. At this temperature, slightly above A

c1

and the short times

caused by the weld thermal cycle, no significant amount of precipitates and hence carbon

(C) and nitrogen (N) go into solution. Therefore, the martensite formed under these

conditions lacks C. This is confirmed by the increase in hardness caused by higher peak

temperatures. Since very small amounts of C go into solution at these peak temperatures,