17

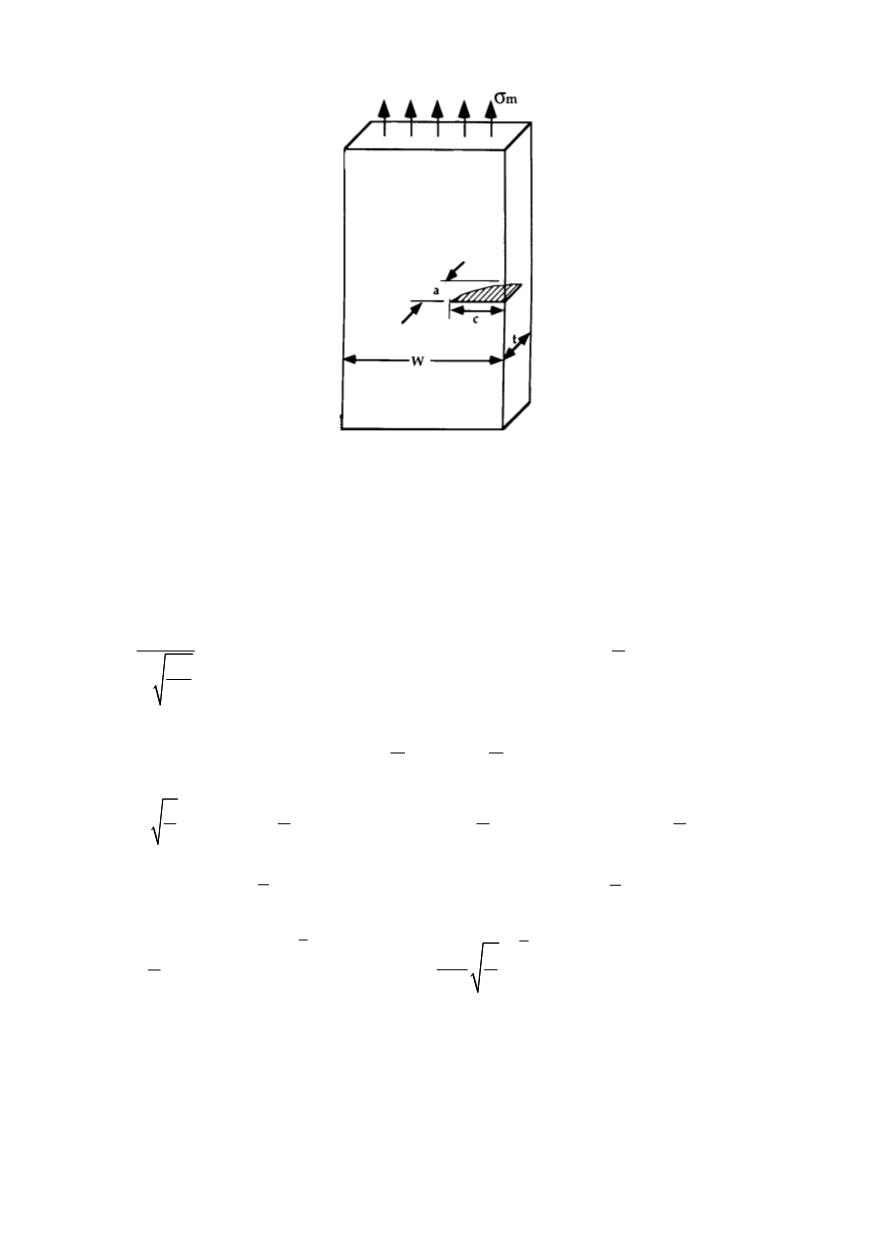

Figure 12: Model of tensile plate with an edge surface crack

For the evaluation of remote tensile stress

σ

(=

σ

m

),

necessary for the final fracture,

rectangular plate is assumed, of thickness

t

= 50 mm and width w = 135 mm in cross

section, through which contained semi-elliptic crack, 14x35 mm in size will propagate in

the material of plane strain fracture toughness

K

Ic

= 64.2 MPa

√

m.

The procedure based on linear elastic fracture mechanics for the angle position

φ

= 0

included following equations used in a sequence /4/:

m

K

a F

Q

σ

π

=

;

282.5

m

MPa

σ

=

(3)

1.65

1 1.464

1.323

c

Q

a

⎛ ⎞

= +

=

⎜ ⎟

⎝ ⎠

(4)

2

4

1

2

3

1 2

w

a

a

F M M M g g f f

t

t

ϕ

⎡

⎤

⎛ ⎞

⎛ ⎞

= +

+

⎢

⎥

⎜ ⎟

⎜ ⎟

⎝ ⎠

⎝ ⎠

⎢

⎥

⎣

⎦

(5)

1

1.08 0.03

0.69

c

c

M

a

a

⎡

⎤ ⎛ ⎞

=

+

= ⎜ ⎟

⎢

⎥

⎝ ⎠

⎣

⎦

;

2

2

0.375

0.06

c

M

a

⎛ ⎞

=

= ⎜ ⎟

⎝ ⎠

;

2

3

0.25

0.04

c

M

a

⎛ ⎞

= −

= −

⎜ ⎟

⎝ ⎠

(

)

2

3

1

1 0.08 0.4

1 sin 1.11

c

g

t

ϕ

⎡

⎤ ⎛ ⎞

= + +

−

=

⎢

⎥ ⎜ ⎟

⎝ ⎠

⎢

⎥

⎣

⎦

,

(

)

2

3

2

1 0.08 0.15

1 cos

1

c

g

t

ϕ

⎡

⎤ ⎛ ⎞

= + +

−

=

⎢

⎥ ⎜ ⎟

⎝ ⎠

⎢

⎥

⎣

⎦

1

2

4

2

2

sin cos

1

c

f

a

ϕ

ϕ

ϕ

⎡

⎤

⎛ ⎞ =

+

=

⎢

⎥

⎜ ⎟

⎝ ⎠ ⎢

⎥

⎣

⎦

,

1

2

sec

1

2

w

c a

f

W t

π

⎡

⎤

⎛

⎞

=

=

⎢

⎥

⎜

⎟

⎜

⎟

⎢

⎥

⎝

⎠

⎣

⎦

;

F

= 0.788

3.6. Conclusion

The examination and analysis of the carriage monoblock wheel fracture causes allows

the following conclusions:

- Fatigue crack emerged under the influence of cyclic stresses induced by braking and

is situated at the highest stress concentration location, chuck marks.