10

2.4. Analysis of weld thermal cycle effects on the bracing and flange plate materials

The material of main bracing was Nb -microalloyed, fine grained, high strength steel,

Table 1. In normalized conditions the steel contains a fine dispersion of NbC precipitate

which stabilizes and refines the grain size. The carbon content is high (0.17%), giving the

steel its fairly high C

equiv

value (0.41). Aluminium (0.044 wt %) is mainly present as a

deoxidizer, there evidently being little or no nitrogen present to form AlN or Nb(CN).

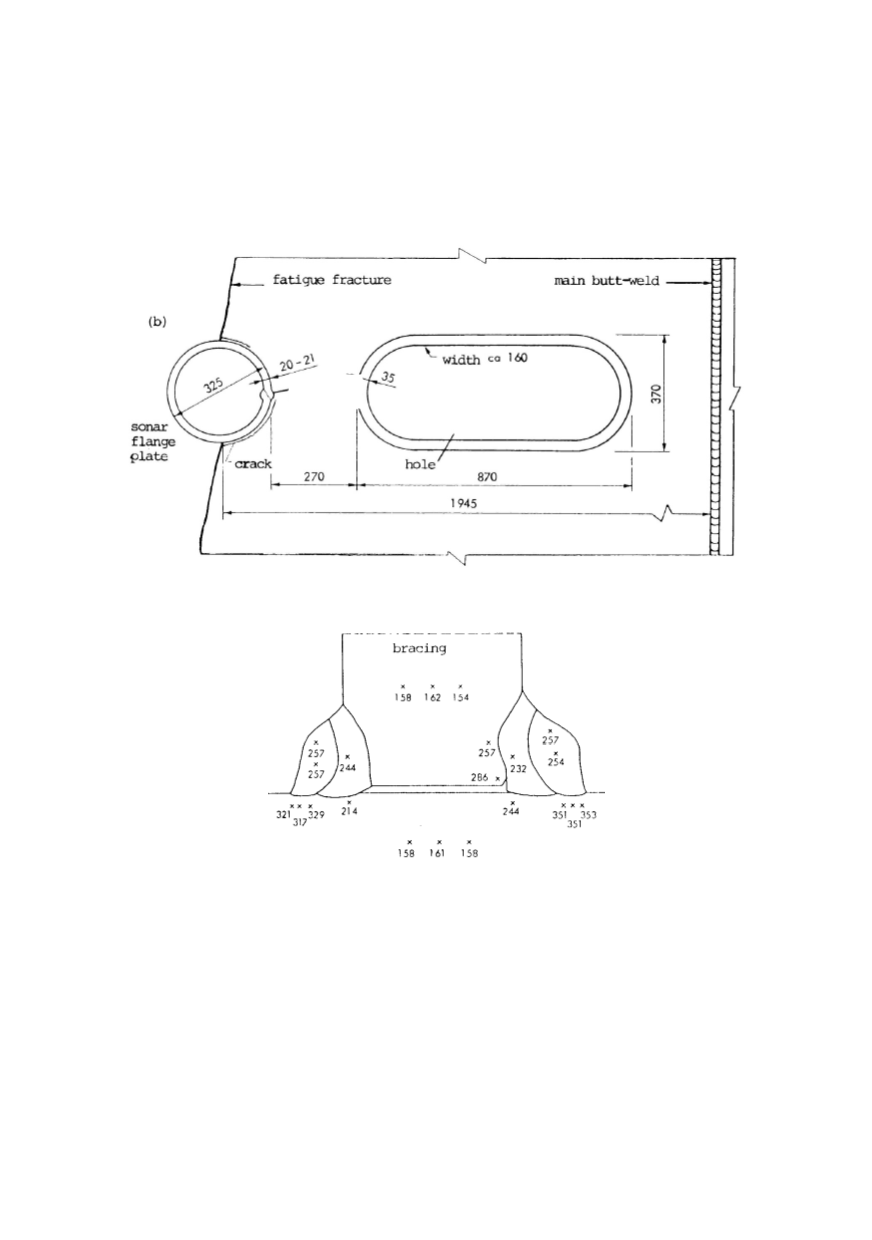

Figure 6: Crack initiating in a fillet weld of sonar flange plate and ending in cracked butt weld.

The position of final fatigue fracture is indicated

Figure 7: Hardness distribution in failed fillet welded joint between bracing and flange plate

The continuous cooling diagram for the steel is similar

to

that shown in Fig. 8 (for the

0.19% C content), in which it is seen that the relatively high cooling rates of MMA

welding are likely to give a mainly bainitic microstructure. The presence of Nb, if it is in

solution in the austenite, further tends to promote the lower bainite transformation. In

other words, this alloy is a typical example of today's sophisticated steels which aim to

possess the ideal combination of high strength and acceptable weldability.

The solubility temperature of NbC in steel is given by equation

[

][ ]

10

1og %Nb %C 2.96 7510 /

T

= −

(1)

and thus it is estimated to be

T

~ 1150

°

C. During a rapid thermal cycle, as in welding, the

carbide is effectively superheated. On this basis, knowing the welding energy

Q

used

Butt-weld

(Cracked)