134

service. The problem is that the quality of inspection might be poor and the conditions

in service stronger than in production, so the larger defects can pass unnoticed.

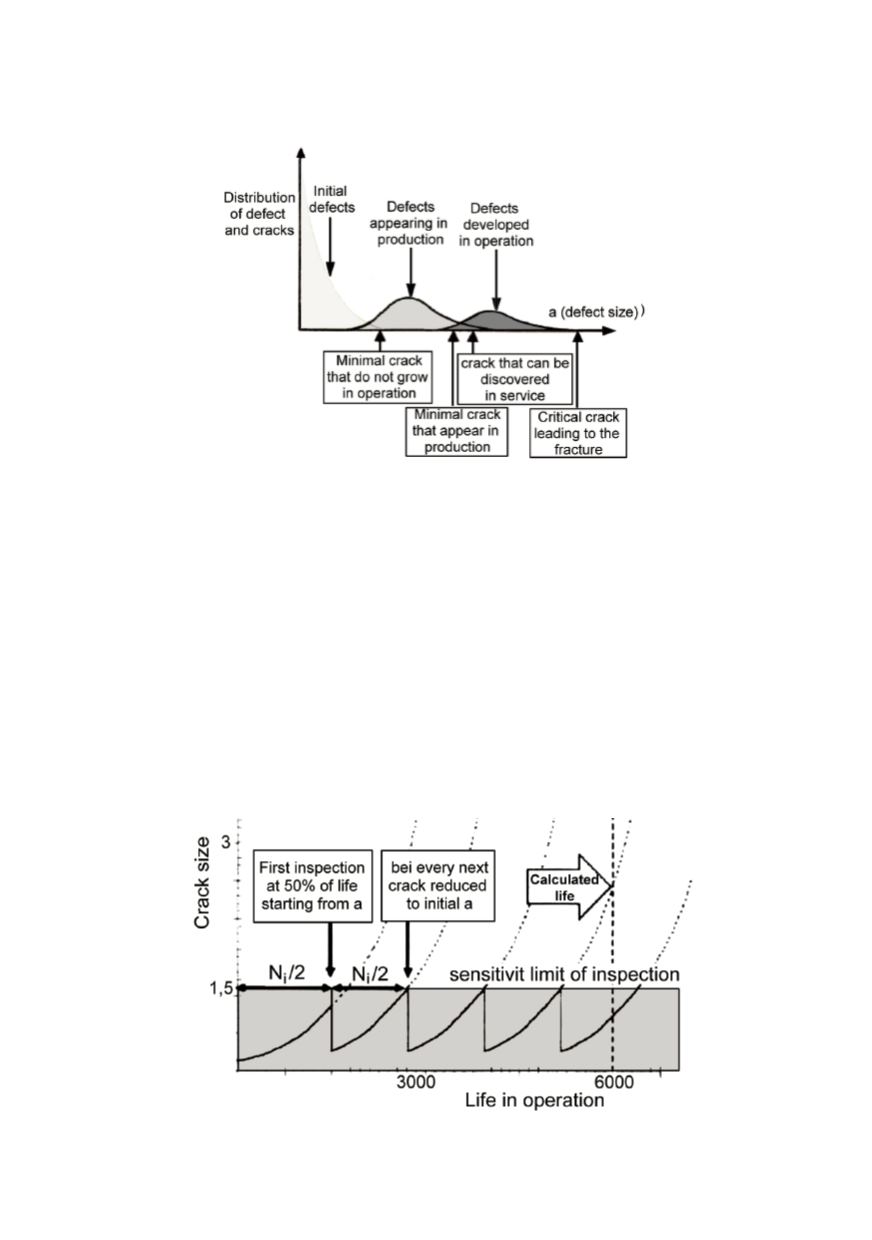

Figure 10: Defect distribution and limit values

Principle FFP-method will be demonstrated on one example whose details are shown

in Fig. 11. Calculated expected design life without cracks is amounted 6000 hours.

Performed analysis showed that crack sized

a

i

= 1.5 mm may stay undetected by applied

inspection sensitivity so that it can grow up to the critical value

a

kr

= 3 during 2800 hours.

For that the first inspection must be carried out by 50% of calculated life based on crack

growth, or after 1400 hours. If by this first inspection the crack still cannot be detected, its

initial size is again assumed to be 1,5 mm and the procedure is repeated. In this way

designed life will be achieved after four inspections. The number of inspections can be

reduced, supposing that the sensitivity of the first inspection is higher. For example, after

production the cracks size of 1 mm can be reliably detected, and in this case can be added

to the life tile first inspection is also half of life corresponding to the crack growth from 1

to 1,5 mm. Even better is if the inspection sensitivity in service can be improved. Direct

saving is measured in this case based on inspection cost reduction, slowdown in

exploitation and the like.

Figure 11: Safe life based on possible crack tolerance