139

detected during inspections before pass through the wall. In practical application LBB

must have sufficient life safety for the safe execution of the necessary action of leakage

establishment, component unloading and necessary repairs. If this is fulfilled LBB can be

accepted as the method of preventing failure or accident in equipment.

Today is the LBB important element of the general approach to the equipment safety,

which is applied to tolerate existing or assumed cracks in a structure for definite period of

operation. The starting point of the LBB procedure is normally a surface crack, which is

in the state for the wall penetration of the pressure containing component. To prove LBB

case for this type of the crack it is necessary to show that:

•

crack breaks the pressure barrier before it may cause fracture,

•

resulting leakage through the wall breakthrough is of sufficient rate, so that its

recovering is possible before crack reaches its critical size leading to the failure

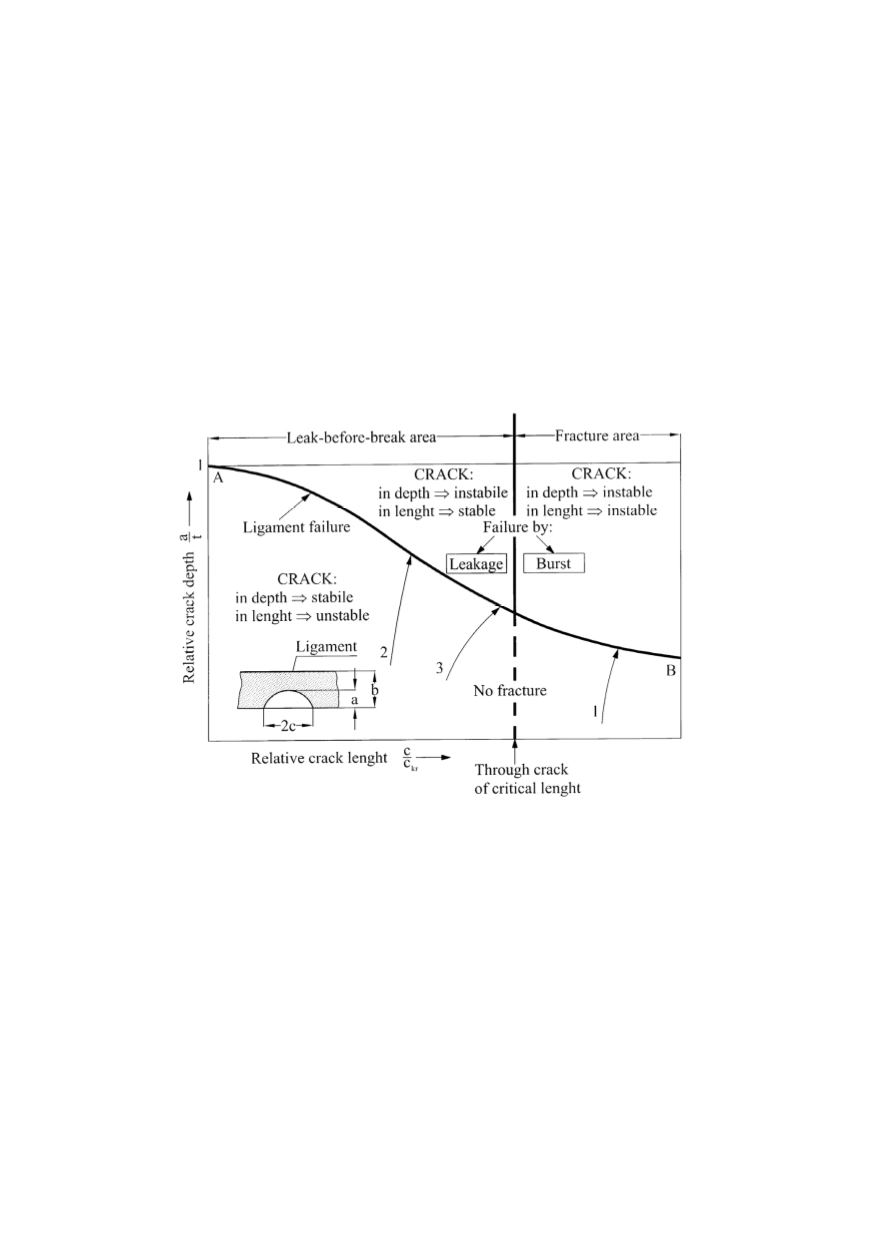

Behaviour of the structure and corresponding relationships can be shown on LBB-

diagram, Fig. 14.

Figure 14: Presentation of the LBB-method (LBB-diagram)

Axes of this diagram are: relative crack depth

a/t

and the relative crack length in

proportion to its critical length

c/c

Kr

. Curve AB defines fracture initiation (crack growth)

for the surface crack. Vertical line at

c/c

Kr

= 1

separates the regions of through crack,

which length is below and above critical size and, because of that, the safe area. However,

surface crack which is longer than

c

Kr

may not cause failure if below of the ligament line.

But if this crack grows in depth (Fig. 14, arrow 1) due to the fatigue or stress corrosion, it

will certainly cause unstable fracture, and for such crack is the LBB-concept not appli-

cable. Structure remains safe only if the crack growth is limited to the area below AB. In

second example (arrow 2) the line of ligament penetration is achieved by crack growth,

and after wall penetration the conditions for leakage can be realised through the further

crack growth along the surface, until the crack opening become sufficient for noticeable

leakage, before the critical length is achieved. The latest is only possible if the crack

growth route (arrow 3) is near to the limit (

c = c

Kr

) in which case catastrophic failure may