39

particularly in the ranges where the solution based on stress intensity factor

K

should be

valid.

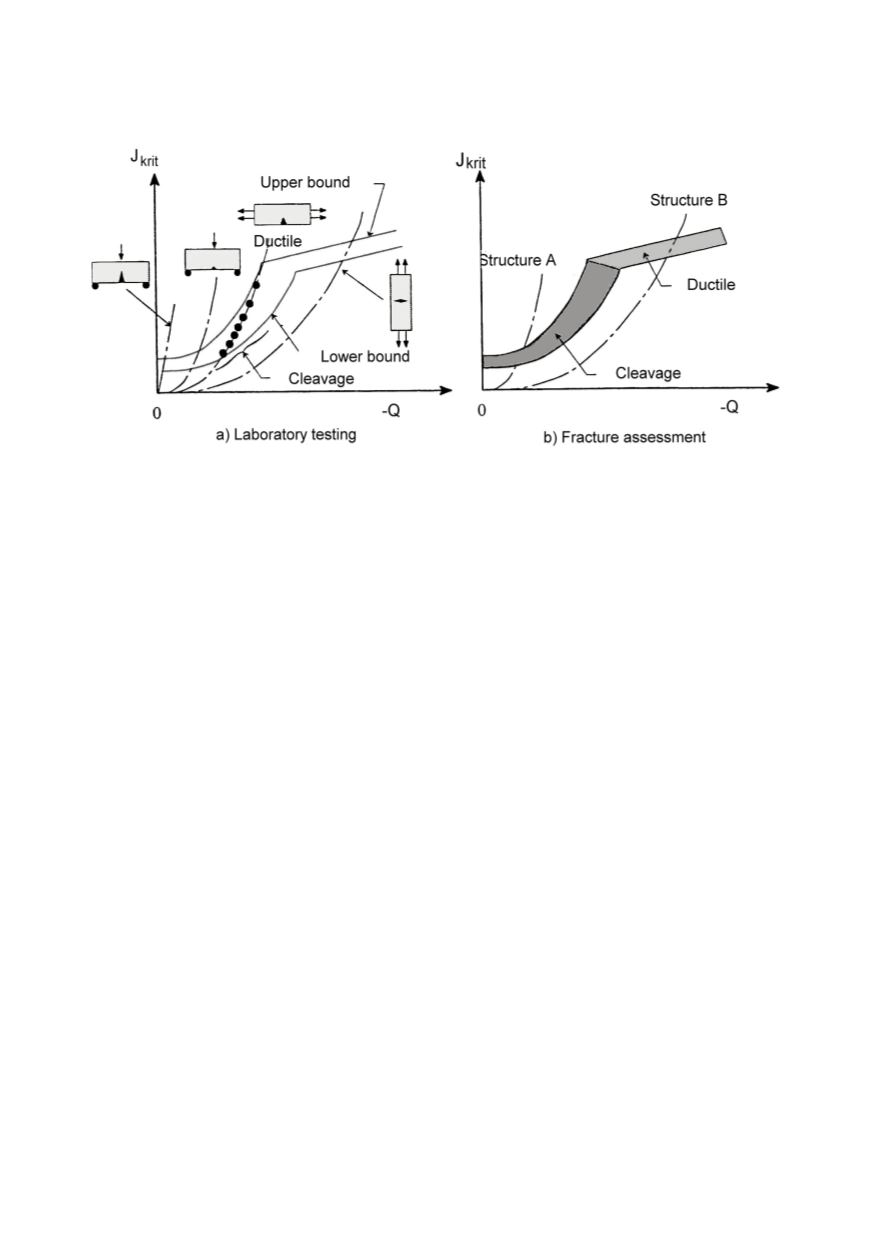

Figure 22: Scheme of J-Q approach (structure A

→

brittle fracture, structure B

→

ductile fracture)

Corresponding EPFM approaches for reliable structural integrity in this case are:

1. Solution based on evaluation of stresses and strains at crack tip (for example based on

HRR solution) and corresponding

J

- integral as criterion.

2. Crack opening displacement as criterion.

3.

Failure Assessments Diagram (FAD), based on fracture mechanics and considers

failure due to plastic collapse.

First two approaches are based on determination of crack driving force (CDF) and the

corresponding procedure can be summed up in following way:

1.

Calculate

J

- integral or Crack Tip Opening Displacement (CTOD)

δ

in dependence

on loading and geometry.

2.

The critical values of

J

- integral (

J

Ic

) and CTOD

(

δ

Ic

) can be determined empirically

by testing standard specimens.

3.

Calculated values of

J

- integral should not be higher than

J

Ic

or CTOD values should

not exceed the critical

δ

Ic

considering required safety margins.

Accordingly, fracture mechanics based on

J

and

δ

application follows the same way as

in the case of LEFM and

K

application. It is expected then that critical conditions at the

crack tip are accurately described by

J

(or

δ

), so that both parameters can be used for the

crack evaluation. Previously discussed limits in this respect should not be overlooked.

5.1. Stress-strain diagrams of material

Important parameter for the calculation that, at the same time, presents the essential

difference to the LEFM procedure is the evaluation and consideration of the elastic-

plastic material behaviour under load. Although the same material and measurement are

applied, this curve is not the same for different methods. Based on use of different

interpretations of the measurements (Fig. 23), the same curve can not be used, since this

will be not in agreement with method requirements. Most often assumption of this curve

is based on true or engineering stress and strain, Ramberg-Osgud curve (Fig. 24):