43

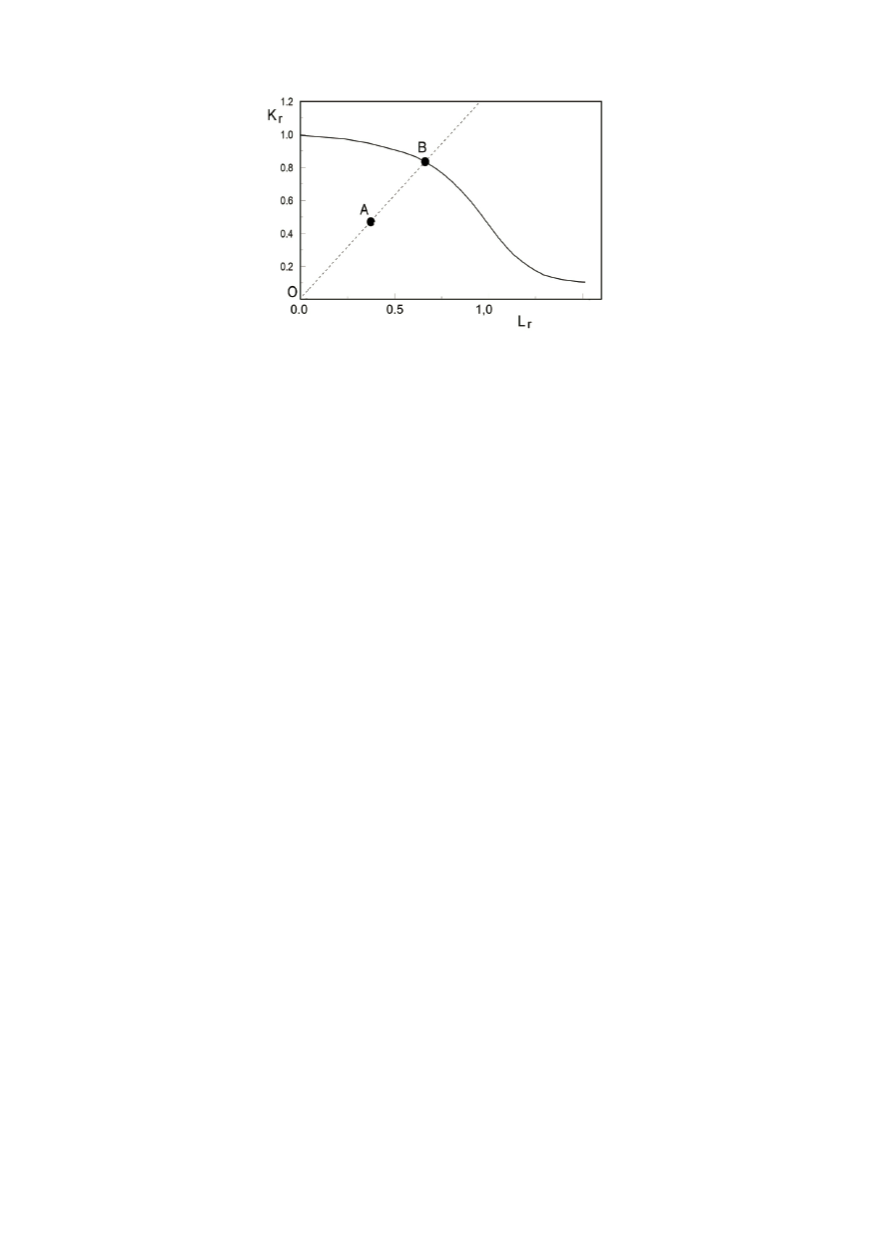

Figure 27: Procedure for determination of safety margins

6. END REMARKS

When the nominal stresses significantly exceed half of yield strength, pure LEFM-

analysis does not consider the risk of underestimation of the crack driving force and the

results could be unsafe. When the plasticity correction is not considered, the results of

LEFM do not give any warning and results validity is questionable. In most complex

cases is better to carry out a robust EPFM analysis, giving valid results from LEFM to

EPFM. In case of corresponding conditions elastic-plastic analysis passes in linear elastic

one and in this way not only become simpler, but gives the results without ambiguity.

REFERENCES

1.

Agatonovic, P.: Fracture Case Studies –Basic Principles, in From Fracture Mechanics to Struc-

ural Integrity Assessment, IFMASS 8, 2003, Ed. S. Sedmak and Z. Radakovic, pp. 159–192.

2.

Agatonovic, P.: Different strategies of remnant strength and life assessment, IVK (2/2001),pp. 5-89.

3.

Agatonovic, P.: Die Restfestigkeit bestimmen, Spannungs-Dehnungs-Annäherung – ein neues

Verfahren, Materialprüfung 41(1999), pp. 24-30.

4.

Agatonovic, P.: K

I

mittels Spannungs-Dehnungs-Annäherung abschätzen: Verifikation des

Verfahrens, Materialprüfung 41(1999), pp. 77-84.

5.

Agatonovic, P.: Development of residual strength evaluation tool based on stress-strain

approximation, International Journal of Fracture 98, pp. 129-152.

6.

Agatonovic, P. and T.K.Henriksen: Development of Residual Strength Prediction Tools for the

Structure Integrity of Launchers Based on Elasto-Plastic Fracture Mechanics, Conf. on

Spacecraft Structures, Materials and Mechanical Testing, 1996, ESA/ESTEC.

7.

Agatonovic, P. and U. Clormann: Analytical Prediction and Test Verification of the Multiaxial

Behaviour of High-strength Steel for Lightweight Structures, Proc. Int. Symp. “Advanced

materials for lightweight structures” ESTEC, ESA SP-336, Oktober 1992.

8.

Agatonovic, P and N. Taylor: Optimisation of a Life Prediction Method for Environmental

Assisted Damage of Components Operating at High Temperature, Kyoto, 1991.

9.

Agatonovic, P. and M. Windisch: Role of Combined Numerical and Experimental Investigation

in the Justification of the Structure Integrity and Damage Tolerance of Space Structure, ESA Int.

Symp. Spacecraft Structures and Mechanical Testing, Noordwijk,NL, 24-26

th

April 1991.

10. Agatonovic, P. et al.: Anwendung kleiner Proben mit Oberflächenriss zur Vorhersage der

Tragfähigkeit von rissbehafteten Bauteilen, In Werkstoffprüfung 1990, Bad Nauheim DVM

Dezember 1990, pp. 213-222.